2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

The most effective, and sometimes the only way to obtain high-precision parts is grinding. For many years, the principle of grinding as a technological process has not undergone any fundamental changes and for several centuries has been the processing of a product with an abrasive material in order to achieve the required accuracy.

. The feed of the workpiece to be ground, which is fixed on a special reciprocating table, can be carried out either manually or hydraulically. Or automatic hydraulics if it is a CNC cylindrical grinder. Also, such equipment can be used for grinding or polishing pipes, on which scratches usually remain during their bending on a pipe bender. For these purposesa circular grinding machine with a special planetary grinding technology is used. It is not a part that rotates in it, but the working parts of the mechanism, as a result of which it is possible to grind bends, including complex configurations.

Cylindrical grinding machine consists of:

- frame, which houses the hydraulic drive;

- turntable;

- of the headstock, which has a drive to the spindle, which transmits rotational motion to the workpiece;

- grinding headstock, which contains the drive to the grinding wheel.

The circular grinding machine is controlled by the handle for changing the speed of the table, the handwheel for manual movement and the reverse handle. Also, the controls include stops, handles for turning on the automatic movement of the table and retracting the quill, a throttle handle that controls the feed of the grinding headstock, a flywheel for regulating the manual feed of this mechanism, as well as a handle for quickly retracting and supplying the grinding headstock and a push-button station.

Cylindrical grinding machines are divided into the following types:

- Simple. For these machines, all nodes are made according to a non-rotary pattern.

- Universal. Depending on the version, they can have both a rotary table and a rotary front and headstock.

- Mortise. The cylindrical plunge grinding machine is devoid of longitudinal feed of the workpiece. The grinding wheel overlapping the workpiece surface additionally receives a continuous feed to the workpiece due towhat is its grinding along the entire length.

- Special. Used for processing products for a specific purpose (for grinding surfaces of turbine blades, tooth profiles, cam shafts, etc.).

Cylindrical grinding machines, most commonly used in our country, are produced both in Russia (for example, the products of the Maikop Machine-Tool Plant named after Frunze or JSC "Shlifverst" in Lubny), and are purchased abroad - in the countries of the former USSR (Ukraine, Lithuania) and far abroad (USA, Switzerland, etc.).

Recommended:

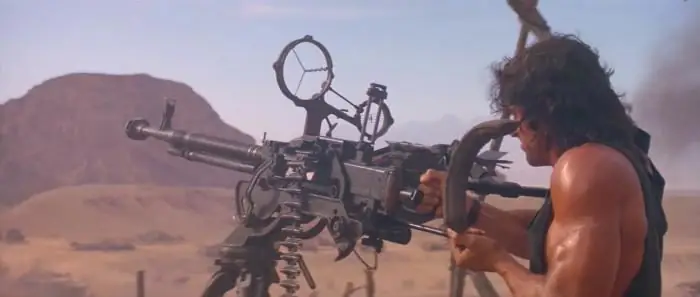

Large-caliber machine guns of Russia and the world. Comparison of heavy machine guns

Even in the First World War, a fundamentally new and terrible weapon appeared on the battlefield. Large-caliber machine guns. In those years, there was no armor that could protect against them, and the shelters that were traditionally used by the infantry (made of earth and wood) generally made their way through with heavy bullets

Grinding machine: varieties and uses

The grinder is a very useful piece of equipment that is used to process wood and stone. Thanks to him, the surface of the processed material becomes even and smooth

What is a technology project? Development of a technological project. Example of a technological project

As part of the article, we will find out what a technological project is, and also work out the issues of its development

Shaft grinding: technique, necessary materials and tools, step-by-step work instructions and expert advice

Today, shaft grinding is quite widely used in such an industry as mechanical engineering. This operation allows the preparation of parts that will have a small roughness, a slight deviation from the shape, etc

Restoration of parts by welding and surfacing: methods and methods of restoration, features, technological process

Welding and surfacing technologies allow efficient restoration of metal parts, providing a high degree of reliability and durability of the product. This is confirmed by the practice of using these methods when performing repair operations in a variety of areas - from car repairs to the production of rolled metal. In the total amount of work on the repair of metal structures, the restoration of parts by welding and surfacing takes about 60-70%