2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

Transformer substations in a system with distribution plants form the necessary voltage regulation nodes in electricity delivery networks. This is a multi-component infrastructure, on which the stability of the supply of industrial, public and private buildings, as well as communications and equipment for various purposes depends. Maintaining the proper functioning of the network allows timely maintenance of the transformer substation and related operating components. These activities are governed by technical documentation and design recommendations developed for the operation of a particular facility.

Basic requirements for maintenance organization

Documents for the operation of electrical distribution installations include the following provisionsregarding maintenance, repair and maintenance of transformer substations:

- Measures aimed at maintaining the working condition of the equipment should focus on protecting the object from premature wear. The same applies to the constituent and auxiliary parts of the substation.

- Repair operations should be aimed at restoring the primary performance of the equipment. These goals are achieved not only by technical means, but also by setting up and calibrating equipment.

- Maintenance for 10/0.4 kV transformer substations should also include control of building structures. In particular, the condition of load-bearing platforms, enclosing structures and foundation platforms is assessed.

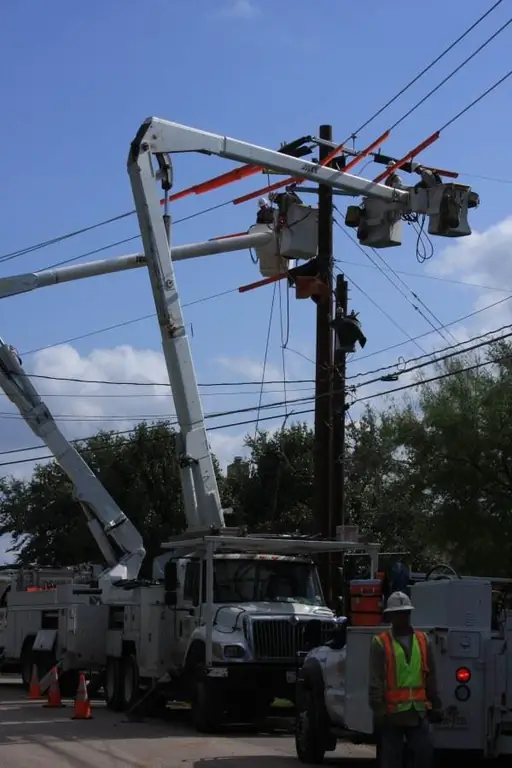

- Specialized teams are allocated for the performance of work, having the appropriate qualifications and provided with the necessary vehicles, installation tools, rigging equipment, communication devices, protective devices, etc.

- If possible, work combined with preventive inspection or repair of adjacent power lines.

Maintenance Schedule

There are regulatory requirements regarding maintenance intervals, but they may be adjusted depending on the current situation and the condition of the equipment. Possible adjustments to the schedule of maintenance activities are made by the chief engineer at the facility. As regards the basicrequirements for the frequency of maintenance of transformer substations, they set the following intervals:

- Regular scheduled examinations - once a year.

- Extraordinary inspection after a disaster - immediately after repair or the next day.

- Extraordinary inspection after failure of a critical component - immediately after the device is repaired or the next day.

- Seasonal inspection - before and after the heating season.

- Checking the grounding - each time a scheduled check of the integrity of the elements of the substation.

- Measurement of network performance - twice a year.

- Major overhaul - once every 6 years.

- Checking the condition of the insulating winding - once every 3 years.

- Comprehensive inspection of protective equipment - once every 3 years.

- Individual work activities (cleaning, tightening, lubrication, etc.) - as needed.

Admission groups for maintenance activities

In accordance with the rules for the operation of electrical installations, there are five qualification groups according to the degree of electrical safety. When taking up a position, service personnel are assigned a status according to their training and professional skills. Sole inspection of substations can be carried out by employees with a tolerance group of at least 3. Only electrical personnel have this qualification. In addition to inspection, employees of this category can connect and disconnect equipment from the network withvoltage of about 1000 V.

As for powerful installations operating with substations on lines with a voltage of more than 1000 V, they can be serviced by administrative and technical personnel of the 4th electrical safety clearance group, but only as part of a team. Workers are allowed to inspect such substations only on the basis of a written order from the management.

Conditions and work order

Maintenance is carried out on the basis of an order for a work permit in accordance with the assigned list of operations within the current operational process. Before performing several work activities at one facility, work order organizers must first coordinate the actions of employees. When servicing a transformer substation in a network with a voltage of up to 1000 V, the following conditions must be met:

- The working area is fenced off, and current-carrying circuits are isolated as far as possible.

- Electricians perform technical operations on an insulating platform, in galoshes made of dielectric material or on a rubber coating.

- Use the tool without insulation only with dielectric gloves.

- Work in clothes with rolled up or short sleeves is not allowed.

- When performing work, positions are excluded in which live parts are located behind the fitter.

Inspection of the transformer substation

Visual inspection involves checking the condition of tires onhigh-voltage bushings near arresters and porcelain insulators. The master must determine the absence or presence of chips, cracks and dirt on the fuses of the transformer substation. The requirements for in-service inspections of operating installations also prescribe the assessment of the condition of thermometers, membrane elements on pipes, the position of automatic valves and indicator silica gel. The oil level is also checked and, if possible, the intensity of its consumption is estimated using measuring equipment.

Online maintenance features

Based on the results of the initial visual inspection of the transformer substation, a decision can be made on the operational (unscheduled) maintenance of the equipment. Operational mobile teams with the appropriate permit are allowed to perform such work. Individual service, in particular, can be performed by employees with the 4th electrical safety clearance group, and as part of the brigade - with the 3rd group.

Online maintenance usually involves setting up or switching electrical installations. For example, if you need to transfer the unit to full voltage when plugged into the network after repair. In this case, the maintenance of the transformer substation will consist in alternately connecting the equipment to the network - with a jogging voltage supply and idling the unit for several hours.

Substation decommissioning

After the inspection, a decision can also be made to withdraw the equipment fromoperation. Such decisions are made due to the physical obsolescence or wear of a number of critical functional elements of the transformer system. But working installations are often written off. For example, if the maintenance and repair of transformer substations is impractical due to high financial costs, with the possibility of using less demanding, but equally productive models. Before the substation is decommissioned, based on the results of the technical examination, the expert commission draws up an appropriate act. Further, based on the recommendations of the manufacturer, the operating organization can dispose of the unit. Moreover, for capacitors impregnated with trichlorobiphenyl, there are special disposal requirements.

Commissioning of the transformer substation

One of the most important activities in the maintenance of electrical installations is commissioning. This set of measures provides for the implementation of commissioning and is carried out after the successful completion of the tests. Specialists check the equipment for operability under maximum load conditions in various modes. Also, after servicing the transformer substation, grounding and lightning protection are provided. Arresters connected to earth are connected to the tested installation. Usually, the short circuit is made to the metal case of the transformer or to adjacent parts of the structure that are connected to the ground.

Conclusion

Organization of maintenance activities at the objects of operation of power grids is technologically complex and multifaceted. The scope of such work may include directly installation operations that require high qualifications from the performers, and the simplest tasks of a preventive nature. For example, initial electrical safety clearance groups do not require special training and allow employees to perform simple verification procedures. In most cases, several groups are combined for comprehensive equipment checks. In parallel, various maintenance activities can be carried out, the general purpose of which will be to detect faults in the transformer substation and then eliminate them.

Recommended:

Air conditioning system maintenance: choosing a company, concluding a contract, rules for registration, act of work performed, maintenance instructions, regulations and safe work

The main task of the ventilation system is to provide access and exhaust air, as well as its filtration and temperature control. In order for these tasks to be fully completed, it is necessary to install special equipment, as well as equip the blower system. Maintenance of the air conditioning and ventilation system is mandatory for both civil and industrial facilities

Workplace maintenance: organization and maintenance of the workplace

An important part of the process of organizing labor in production is the organization of the workplace. Performance depends on the correctness of this process. An employee of the company should not be distracted in his activities from the fulfillment of the tasks assigned to him. To do this, it is necessary to pay due attention to the organization of his workplace. This will be discussed further

Electricity distribution: substations, necessary equipment, distribution conditions, application, accounting and control rules

Everyone knows that electrical energy is supplied to the place of its consumption from a direct source. However, such sources can be located at a great distance from the consumer. Because of this, the distribution of electricity and its delivery is a rather complicated process

Briefing at the workplace: program, frequency and registration of the lesson in the journal. Introductory, primary and repeated briefing at the workplace

The purpose of any briefing is to ensure the safety of the employees of the organization, as well as the property, equipment and devices that are in its ownership. In order for the production process to run smoothly, and the result of the organization's work to be at the highest level, it is necessary to carry out briefing at the workplace

What is an electrical substation? Electrical substations and switchgear

Trams and trolleybuses require voltage not alternating, but constant. This means that a separate very powerful substation is needed. Electrical energy is converted on it, that is, it is rectified