2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

All poultry farmers know that the process of plucking carcasses is quite laborious and lengthy. It is good if there are few carcasses and you can clean them manually. But if you need to pluck a large number of them, it is very problematic to deal with this manually. In this case, you can not do without a plucking machine.

Types of pen devices

Technologists have developed an amazing mechanism that allows you to clean the bird from feathers in a few minutes. All removable structures are divided into:

- industrial;

- household.

Industrial devices are large, they are equipped with poultry farms. Household vary depending on the power and volume. Some of them allow you to load several carcasses. Others are designed for only one. The price of the structure will also depend on the volume.

Household machines can be purchased at stores that offer special equipment for farmers. The removable structure can be made independently. The in-house manufacturing process requires materials and blueprints.

How does a picking machine work?

The feather-plucking machine ensures the speed of removing the feather from the bird. AtIn this case, the carcass is not damaged, and the feathers are completely removed. Before immersion in the apparatus, the carcass is scalded with boiling water, put into the machine and the engine is turned on.

Unfortunately, such a device has a high cost - about 25-35 thousand rubles. Not every farmer can afford to buy it. But do not despair, because it is quite possible to make such a design on your own.

The plucking machine consists of a drum studded with rubber fingers inside and operates on the principle of a centrifuge. After switching on, the bottom rotates, the carcass turns over. Rubber processes pick up feathers, pull them out. The water washes the feather out. It takes no more than a couple of minutes to process one carcass. Up to 30 carcasses can be plucked in an hour.

Search Parts

To make a do-it-yourself plucking machine, you should start by preparing all the necessary details. The most important question that arises before the master: where to get beats? Farmers with experience in self-manufacturing of the unit are advised to order these parts. Yes, the purchase will not be cheap, but this is the biggest waste in the manufacturing process. Each finger costs about 10 rubles, and one design requires about a hundred beats. All other items can be found almost for free.

When ordering, please note that beaters vary in size. The largest ones are suitable for plucking turkeys and geese, the smaller ones for broiler carcasses, the smallest ones for assembling a quail plucking machine. You can order pickle fingers online at farm supply stores.

Reconstruction of the washing machine

For a plucking machine from a washing machine, you will need an old but working Oka. The process of its alteration will be minimal. You will need to move the engine and electrics outside. To do this:

- dismantle the engine;

- remove the activator and drive device;

- take out all the electrics and carefully set aside.

Then you need to prepare a rubber hose and put a shower head on it.

Preparation of tools

To create a plucking machine, you need tools:

- open-end wrenches;

- adjustable wrench;

- ratchet with different heads;

- angle grinder;

- drill;

- pliers;

- ruler;

- multimeter;

- felt pen.

This is the main list of tools. Perhaps something else will be required in the process of work.

Assembly process

Some craftsmen advise making a plucking machine for geese from plastic containers, supplementing it with beaters and a drive structure. Using a washing machine is convenient because it already has a drive and activator mechanisms, as well as an engine.

However, there is some difficulty. Through the holes for rubber fingers and for water drainage, water will flow out and fall on the engine and electrics. It is unacceptable. That's whyyou need to do this:

- motor must be protected with a plastic case from any appropriate box, a metal corner will do as a base;

- to test the engine, you need to plug it into an outlet;

- metal corners are used to make a reliable base;

- two pulleys of the washing machine are put on the shafts of the motor and the activator device and connected by a belt;

- when checking the operation, the engine must start the activator;

- next, gaps are made into which rubber beaters will be installed, the distance between them is 3 cm;

- need also larger holes to drain water and feathers;

- gaps for beaters need to be lubricated with machine oil, beaters can be installed;

- the hose is attached to the edge, while the shower head should look inside.

The plucking machine is ready.

The watering system of the carcass will help to clean it much faster than the process performed without water.

If a washing machine is not available, you can replace it with any other cylinder made of metal or plastic. Usually containers with parameters of 70 by 80 cm are used. If a metal cylinder is selected, the thickness of the metal should be more than 1.2 mm. They also drill holes for the fingers, while taking into account that the beaters must hold very firmly. The bottom of the cylinder is cut off, fingers are also attached to it. The bottom is connected with a sleeve with a circle of plywood. A disk is put on the sleeve from below, which is connected to the engine.

As a basis, you canmake a wooden structure. An ordinary wooden frame with four legs connected by crossbars will do. To prevent water from splashing up, a plastic cover is needed. In conclusion, the cylinder is fixed in a wooden frame.

The process of creating your own feather design is simple. The main thing is to show care and patience, and you can enjoy the created device for a long time.

Recommended:

Large-caliber machine guns of Russia and the world. Comparison of heavy machine guns

Even in the First World War, a fundamentally new and terrible weapon appeared on the battlefield. Large-caliber machine guns. In those years, there was no armor that could protect against them, and the shelters that were traditionally used by the infantry (made of earth and wood) generally made their way through with heavy bullets

RPK-16 machine gun: specifications. Kalashnikov light machine gun

At the international presentation of weapons "Army-2016", held in September 2016, the RPK-16 machine gun, the brainchild of domestic gunsmiths, was demonstrated. It will be discussed in this article

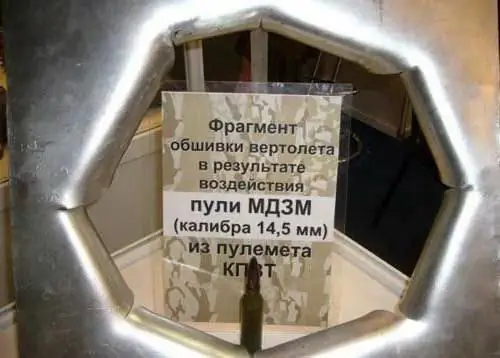

KPVT, machine gun. Heavy machine gun Vladimirov KPV

The idea of defeating aircraft and lightly armored vehicles led to the creation of heavy machine guns with a caliber of more than 12 mm. Such machine guns were already able to hit a lightly armored target, get a low-flying aircraft or helicopter, as well as shelters behind which there was infantry. According to the classification of small arms, the 14.5-mm KPVT machine gun is already adjacent to artillery weapons. And in design, heavy machine guns have much in common with automatic guns

Balancing machine: instructions for use. Balancing machine errors

Balancing machine: characteristics, instructions, operation, features. Do-it-yourself balancing machine: recommendations, device. Balancing machine errors: description

DIY metal bending machine: features, drawings and recommendations

At present, when many buildings and products are made of metal, the relevance of the metal bending machine is becoming more and more. Buying such a device will be quite expensive, but the plus is that it is quite possible to assemble it yourself