2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Most often, to work with metal blanks, a person needs a metal bending machine. This is a fairly simple device, but its usefulness cannot be overestimated. In addition, it is quite possible to make it yourself. This will save a significant amount of material resources, but it will also require certain knowledge, skills and, of course, time.

Description

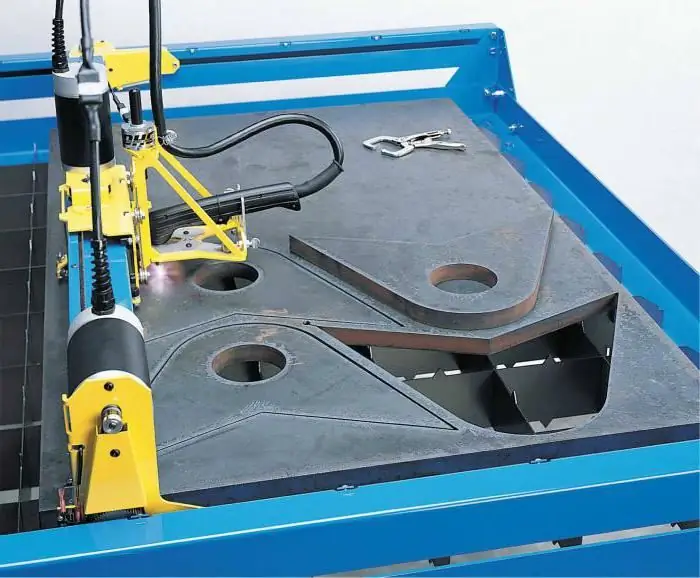

Metal bending machine, as its name implies, is used to produce bent metal parts. It is worth adding that, in addition to this function, it can also have one additional one - material cutting. Such machines are most often used to produce strips of metal. In addition to these two functions, the presence of such a machine will allow the production of various kinds of profiled metal. The advantage of using a metal bending machine is that it allows you to change the shape of the material at any required angle, but at the same time it does not harm the surface coating or the protective layer of the product.

Work on the unit

You can work on such a machine not only with steel products, but also with copper, brass, aluminum and iron. If a workpiece made of any material is characterized by the fact that its thickness is less than 0.8 mm, then its width must necessarily be not less than 40 cm, but not more than 2.5 m. With such dimensions, the height of the shelf (for bending) must be no more than 2 cm. If you want to cut blanks with the same thickness, then it is important that their width is from 80 mm to 40 cm and no more.

Another important condition that must be observed in order to work on a metal bending machine is the absence of defects on the surface of the sheet that will be bent. Compliance with this condition is important so that those parts and samples of products that will be produced on a home-made machine with your own hands are not inferior in quality to those blanks that are produced on an industrial scale in factories. In order to protect the polymer or paint coating on the material itself, it is recommended to install silicone or rubber pads on the machine.

The design of the machine for bending sheet metal, made by hand

A homemade machine for bending metal products has a fairly simple but very functional design, consisting of several basic elements.

Knife. Since the machine has an additional cutting function, this part is also the main one. It should be installed on movable rollers, and is intended for cutting workpieces. Here it is importantnote that this element must be made of very strong steel, on the Rockwell scale, the strength level should be about 100. The service life of such a product is quite long, but it will be difficult to sharpen. But this drawback is completely offset by the fact that the knife will allow you to cut a huge number of linear meters of material before it becomes dull. To make it easier to move the rollers, they must be weighted.

Component parts of the machine

A do-it-yourself metal bending machine must also have several of the following constituent elements:

- The required part is a working beam (table). The purpose of this element is quite clear, it plays the role of a working surface on which the workpiece lies. The width of the beam can be almost any. It is worth noting that if the dimensions are quite large, then the machine for bending metal with your own hands can be turned into a full-fledged workbench. Masters recommend making or covering the surface of the beam with rubber or silicone so as not to scratch the surface of the workpieces.

- Next comes the sheet bender itself. The design is quite simple and should be made in the form of a frame made of wood material, and also have a weighting agent.

- It is necessary to acquire various supports and stops that will prevent the material from slipping.

- Another important element is the sheet fold stops. These details will adjust the fold width of the sheet and set the fold angle.

- Tocut blanks, it is recommended to add stops to indicate the width of the cut.

Start making a homemade metal bending machine

It is recommended to start work by drawing up a diagram of the unit. It is also necessary to purchase and manufacture all the necessary elements and parts before proceeding with the assembly. The first thing you need to buy is two pieces of channel No. 5 and No. 6 with the same length. Also, these two elements must have a straight edge. These elements are used to prepare the base. Piece No. 5 is used for clamping, and No. 6 for arranging the base. To choose the length of the channels, it is necessary to build on the length of the workpieces with which you plan to work, this parameter must match. Most often, experts recommend taking a length of about half a meter. This is enough to make almost any part that can be useful in everyday life.

Production and assembly of the machine

Further, for the manufacture of a machine for manual bending of metal, it is necessary to make holes on the channel, which is clamping. The number of holes should be from 2 to 4, and their diameter should be equal to 9 mm. The hole closest to the end of the workpiece of the clamping part should be located 3 cm from the edge. Another important point is that the clamping device must be shorter than the base, by about 5-10 cm.than future preparations. A lever handle is best made from materials such as rebar or timber. If a beam is used, then its cross section must be no less than 15 mm, and if a beam is taken, then its dimensions must be at least 50x50. The shape of the lever is recommended to be U-shaped. This element is attached to the corner by welding or bolts.

Final works

After all the previous manipulations have been completed, you can start making such an element as cheeks. They are made of rolled steel, and the thickness of the parts should be about 5 mm. It is important that these elements have chamfers, the thickness of which should be equal to 0.6 cm. The length of this section should be from 3 to 3.3 cm. It is important that the ends of the punch are also chamfered with parameters such as 0.5 cm deep and 3 cm long. They must be removed from the punch to allow the axle to be installed. The production of such an element as an axis is carried out from metal rods, whose diameter is 1 cm. The axis is fastened by welding. When installing, it is necessary to ensure that the axis line is parallel to the corner ribs. All this finished structure, together with the punch, is connected using a vice. When combining, it is important to ensure that the free shelf of the corners is located in the same horizontal plane in which the free channel shelf is located.

After that, the assembly work can be considered completed. In order to check the performance of the machine, it is recommended to take a blank of mild steel withup to 1.5 mm thick. It is worth noting that the price of a purchased metal bending machine can reach up to $2,000.

Sheet bending process

The design of a homemade machine can also consist of such parts as a bed, a flywheel nut, a bending sheet, a clamp, a pipe, a punch for crimping. In order to work on this type of machine, certain knowledge and skills are required. The advantage of using this unit is that it will keep the metal intact, unlike the same welding.

In the process of bending the metal, the following happens: the outer layers of the metal blank are stretched, but the inner ones, on the contrary, are compressed. It is important that in order to bend a metal workpiece, it is necessary to apply such a force that will be greater than the ultimate elasticity of the material. With the help of metal bending machines, this condition can be achieved. The advantages of the finished product, that is, bent sheets, include the following factors:

- presence of high strength end product;

- possibility of obtaining a one-piece structure without welds, bolted joints, etc.;

- the possibility of corrosion is excluded, since there is no damage to the metal during the bending process;

- possibility to get the desired angle without creating a weld.

Conclusion

The presence of such equipment at home greatly simplifies the work with metal blanks. However, when operating this device, it is extremely important to know and adhere to the techniquesecurity. The price of a do-it-yourself sheet metal bending machine will also be significantly lower than a purchased one. You will have to spend money only on those materials that will not be at hand and will have to be bought.

Recommended:

Sheet metal cutting: description, types. metal bending

Today, sheet metal cutting is one of the fairly common technological processes that allows you to get blanks of the desired size and shape. However, there are many methods for performing this procedure and a wide variety of equipment

Pipe bending: technology description, features and methods

A plastic pipe is a PVC product with a reinforcing layer inside. Thanks to the rapid development of modern technology, such materials quickly replaced heavy and bulky cast iron pipes from the construction industry. Therefore, at home, when arranging underfloor heating and installing a water supply system, the question often arises of how to bend pipes. You will find a description of the technology, features and methods of working with PVC pipes in our article

Connection of HDPE pipes with a metal pipe: features, practical recommendations and reviews

If you decide to connect HDPE pipes to metal pipes, then it is important to familiarize yourself with the basic technologies for the work. When threading metal HDPE pipes of small diameter up to 40 mm, it is best to use fittings that have a thread for a metal pipe

Metal cutting machine. Plasma metal cutting machine

The article is devoted to the apparatus for cutting metal. The technology of plasma cutting, as well as the device and features of the equipment are considered

Reinforcement of the floor slab: step by step instructions, features and drawings

The example of reinforcing a monolithic floor slab described in the article involves the use of a mesh that binds itself. The rods must be laid along the length, while gaps should be excluded. If there is a need for a tie, the metal elements must be laid with an overlap of 0.5 m