2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

Cement is one of the most common and important building materials, without which modern construction cannot do. As a component, it is used for the manufacture of various solutions and mixtures. All buildings erected over the past 200 years were created with his participation. What is made of cement, what types exist and where are they used? Let's try to answer all these questions.

Composition

The starting material is a dry powder substance of artificial origin. It is obtained by grinding and mixing clinker, gypsum, as well as various fillers and additives. However, it is clinker that is the basis of the mixture. It is obtained by grinding and roasting limestone, clay and various mineral components. Depending on the percentage of content in the composition of these elements, the properties and area of \u200b\u200buse of cement will differ.

What is made of cement during construction is based on a chemical reaction in whichpowder when interacting with water turns into a doughy mixture. In the future, under certain physico-chemical processes, the liquid mixture is transformed into a solid one. As a result, the cement mixture acquires a stone-like structure.

Speaking of what is made of cement, one can first of all single out ready-mixed concrete, reinforced concrete products created at the factory or directly at the construction site. It is also used to produce asbestos-cement materials, plaster, masonry and other building mixtures and mortars.

At the moment, about 40 types of cement are known, each of which finds its application to create a particular structure. Consider some varieties.

Portland cement

This is the most common type used for precast concrete products. High-quality ready-mixed concrete is made from it, which is used in construction to create load-bearing elements of buildings and structures. If you believe the statistics, then it accounts for about 60% of the total volume of produced types of cement per year. In addition, it is Portland cement clinker that is the basis for the manufacture of other types of cement. Structural columns, walls, and cement slabs can be made from this building material.

White and colored Portland cement

Obviously, ordinary Portland cement is gray, as it contains a large amount of iron and manganese. But if the content of these oxides in the clinker is insignificant, and whenits production used white clay, then the Portland cement mixture acquires a light white hue. It is not used to create durable load-bearing structures. Most often it is used for decorative and finishing works.

A feature of the production of the material is that raw materials are fired on a special ash-free fuel.

As for non-ferrous raw materials, they are made on the basis of white Portland cement. A small amount of gypsum and a special colored filler are simply added to it. It is easy to guess that it is used for decorative purposes, in particular, for obtaining colored surfaces, making textural elements and details, and making facing materials.

Slagportlandcement

This belongs to the group of hydraulic binders. It is made by grinding and subsequent grinding of Portland cement clinker, blast furnace slag and building gypsum. It is known that various wall blocks, building dry mixes and plaster bases are made from this type of cement.

Expanding

This material also belongs to the group of hydraulic binders. It has one difference from other materials, which, when used, decrease in volume and mass. Expanding cement does not shrink. Moreover, the hydration and hardening process is accompanied by volume expansion, especially in the first stage after setting.

This type of cement is used for the manufacture of injection and repair compounds that are used in the overhaul of damaged reinforced concretedesigns.

Conclusion

Given the properties of this material, anything can be made from it. Nothing prevents you from creating a wall panel or cement-sand tiles based on it. Almost any correct and even irregular shape of building elements can be created in factories and even on construction sites.

This versatile material is the backbone of any building structure. Buildings always begin to be built with a foundation, which is necessarily based on high-strength concrete created from a cement mixture. Further, during the construction, reinforced concrete structural elements are used, and the construction is completed with a roof covering device, in the form of which cement-sand tiles can act. It has become very popular lately. Also, decorative finishing works are often applied using cement mortar.

Consequently, the importance of this material in modern construction cannot be overestimated. This is the cheapest, most convenient and durable element, the use of which is 100% justified.

Recommended:

What is milk made of? How is milk powder made?

Surely everyone is concerned about the question of what milk is made of. In this article we will try to find answers to it and learn a lot about this product familiar from childhood

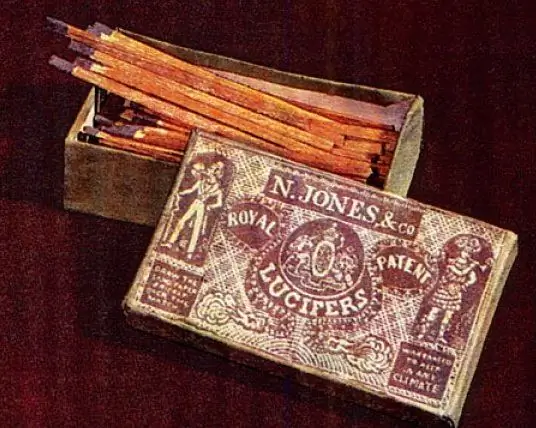

How were matches made before and how are they made today? Swedish matches

The article is devoted to the history of the creation of matches - from their very first prototypes to modern ones. It also tells about the famous Swedish matches, the evolution of the chemical components of the match head and stickers for the box

Types of investors: institutional, private and foreign. Enterprise valuation for different types of investors

In the modern world, people have access to many different sources and ways of earning income. Someone prefers to choose the traditional path, getting hired. And there are those who find alternative options for themselves. For example, investing. This method allows you to receive passive income. However, for many, it still seems difficult

Maximum and average weight of a ram at different ages: an overview of different breeds

Sheep are very popular farm animals. Sheep are bred in almost all corners of the world, including in unfavorable natural areas. These animals were domesticated a very long time ago - in the 6th-7th centuries BC. In addition to unpretentiousness, farmers also attribute the ability to quickly gain muscle mass with low feed costs to the pluses of sheep

Preparing for repairs: what cement is made of

If you plan to build or do repairs on your own, then you need to know what cement is made of, as well as how to properly prepare its solution