2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:25

A cozy home is a home that is warm and light. The indicator of comfortable temperature in it depends on the heating scheme. In apartment buildings there are centralized heating systems. Therefore, the temperature in the premises depends directly on the work of utilities.

Heating schemes in private dwellings are arranged differently. In the past, most houses were heated with wood. For this, stoves and fireplaces were built.

Now heating systems have been significantly upgraded. Not only they are being improved, but also the fuel that is used.

Briefly about the main sources of heat in homes

Electricity or gas, wood or briquettes are often used to heat private housing. To select the most efficient type of fuel, it is worth briefly familiarizing yourself with some of them.

Electricity

Heating starts the last stage of construction. This is one of the finalhousing communications. Electricity is used when it is impossible to connect other types of space heating. In the process of building a house, rooms are often heated using electric heaters or from various power generators.

Gas

Natural gas is used if it is possible to bring it to the house, the availability and connection of the appropriate certified equipment. It should be noted the high cost of arranging a private dwelling with gas.

Firewood

In Russia and neighboring states rich in forests, firewood is a popular type of fuel. It is inexpensive, environmentally friendly, affordable. To use it, you do not need to purchase special boilers, batteries. But this fuel has become significantly inferior to briquettes.

What is compressed fuel, what are its pros and cons, is it worth using?

Briquettes

First of all, briquettes are pressed fuel from the husks of agricultural materials, from peat, coal chips, and waste from the woodworking industry. Regardless of the material from which the production of briquettes is carried out, the processes of shrinkage and pressing of the feedstock are mandatory steps.

Types of briquettes

Recently, wood briquettes are gaining more and more popularity. Until recently, a significant proportion was occupied by coal and peat species. But the production of fuel briquettes is not always harmless to the ecosystems in the places of production.

Charcoal briquettes

Several decades ago, many people heated their homescoal based fuel. The production of briquettes from this raw material is carried out next to the coal mining enterprises. In this case, the starting material is coal chips, dust. Mining waste is poured into the press, and the output is smooth, regular shaped briquettes. Then they are dried to obtain a moisture index in accordance with government standards.

Peat briquettes

Production of fuel briquettes from peat is a long process. The main deposits are located in swampy areas. Before taking peat, these lands need to be dried out by means of land reclamation, which harms the flora and fauna of these places.

The process begins with the construction of channels through which water is pumped out. All vegetation is removed. This takes about three to four years. The top layer of earth is milled, then turned over and dried in the sun. After that, it is raked into shafts, which are removed and mountains of peat are already poured. Properly collected and folded raw materials are not afraid of rain or snow.

After the extraction and processing of peat on the site, it is fed to the production workshops. First, the raw materials are poured into dryers, where its moisture content is reduced to twenty percent. Then the press lays it in the troughs, where it goes in a continuous band. At the end of the gutter, the peat falls off under its own weight in pieces of equal length.

The formed bars go to the warehouse or immediately for shipment and delivery to the buyer. Consumers know that such briquettes are more convenient to use than loose peat. They are less dustymore convenient to fold in storage spaces.

What are wood briquettes

All chips, wood trimmings obtained by sawing trees are sent to special crushing units. Few people know that such briquettes as wood briquettes are made from these wastes of woodworking enterprises. The resulting crushed secondary raw material is dried to a moisture content of four percent. After that, it is fed into the main equipment for briquettes (i.e., for their manufacture) - a pressing machine. Under a pressure of 300 atmospheres, a bar of a given shape is formed. The secret to long burning lies in the high density of the briquette and the low oxygen content compared to wood.

Advantages of briquettes

The main advantage of compressed fuel production is the minimization of waste emissions. Most briquettes are made from recycled materials from coal and wood mining and processing enterprises.

For end users, the undoubted advantage of fuel bars is their compactness. They take up much less space than wood or coal. Wood briquettes have the lowest ash content. They leave little to no ash or clog chimneys.

The burning time of compressed fuel is several times higher than that of conventional fuels. This is an excellent option for heating private houses. It is enough to put briquettes in the furnace, set fire to it. gradual uniformcombustion of the sticks will make it possible to maintain a comfortable temperature in the premises for a long time.

Disadvantages of compressed fuel

Some consumers are frustrated by the low ash content of briquettes. This is frustrating for gardeners who use the remains of the fire as fertilizer.

The disadvantage of briquettes is their high hygroscopicity. When pressing raw materials, a dense layer is formed on the surface of the bars, preventing moisture from penetrating inside. But if the manufacturing or storage technology is violated, they can become vulnerable. Therefore, purchased briquettes are recommended to be kept in dry, well-ventilated areas.

Briquettes from coal and peat have a higher percentage of ash content, compared to firewood or wood briquettes. When using them, it is necessary to periodically clean pipes and chimneys to prevent obstruction.

Charcoal briquettes smell unpleasantly of sulfur. They are very dirty. When laying in the firebox, you can get dirty.

Cost

The price of briquettes depends on the raw materials from which they are made. PiniKay brand wood blocks are the most expensive - from ten and a half thousand rubles.

Briquettes made of RUF wood cost from eight and a half thousand rubles per ton. The price of peat briquettes "Standard" is approximately 8,000 rubles per ton.

Anthracite coal used for space heating costs about eleven thousand per ton, and grade D costs about nine thousand.

Before installing and connecting fuel equipment, it is worthconsider what kind of fuel will be used. In the absence of conducted gas, lack of money for the purchase, installation, connection of equipment, it is more convenient to use wood briquettes. Due to the long combustion process, they can provide a constant temperature in living rooms. They have the lowest ash content. Use does not lead to pollution of chimneys of fireplaces. According to consumer reviews of briquettes, most of them consider them an environmentally friendly, convenient, economical type of fuel.

Recommended:

Amphoteric surfactants: what they are made of, types, classification, principle of action, additives in household chemicals, pros and cons of use

Today there are two opinions. Some say that amphoteric surfactants are harmful substances that should not be used. Others argue that it is not so dangerous at all, but their use is necessary. To understand why this dispute arose, it is necessary to understand what these components are

Solid fuel is Types, characteristics and production of solid fuel

Non-fossil solid fuel based on wood and industrial waste - affordable and efficient fuel. The modern market offers a wide range of solid fuels, differing in efficiency and characteristics

Biodiesel fuel: properties, pros and cons

Biodiesel fuel has been around for a long time. However, not every person can explain what is the difference between conventional diesel fuel and biodiesel. This article will dispel myths and give a clear idea of the methods and stages of biodiesel synthesis, as well as its disadvantages and advantages

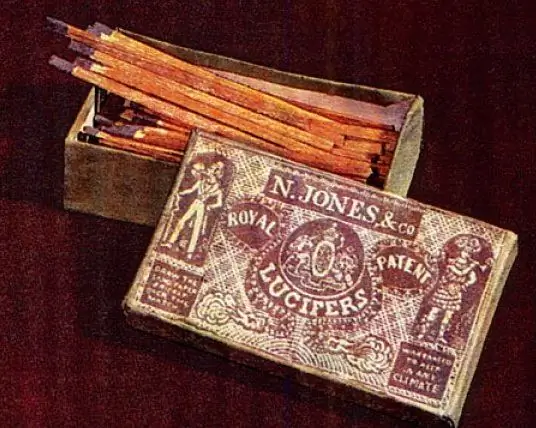

How were matches made before and how are they made today? Swedish matches

The article is devoted to the history of the creation of matches - from their very first prototypes to modern ones. It also tells about the famous Swedish matches, the evolution of the chemical components of the match head and stickers for the box

Fuel consumption of an aircraft: types, characteristics, displacement, amount of fuel and refueling

Fuel consumption of an aircraft is one of the important indicators of the efficient operation of mechanisms. Each model consumes its own amount, tankers calculate this parameter so that the airliner is not loaded with excess weight. Various factors are considered before allowing a departure: flight range, availability of alternate airfields, weather conditions of the route