2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:26

Many are interested in what kind of work is a presser-vulcanizer. This specialist processes rubber products using volcanic hydraulic presses. Moreover, depending on the capacity, he can be entrusted with presses with electric or steam heating. What is it for?

In general, vulcanization is a chemical process that changes the performance of rubber. After processing on special equipment, it becomes harder and at the same time elastic.

Low rank employees prepare equipment, lay down and collect molds. Masters with a higher category carry out the process itself, taking into account the regulations and indications of instrumentation. What a presser-vulcanizer does at an enterprise depends on his category, qualifications, and the focus of the company's work.and other factors.

Knowledge

When applying for a job, an employee must have a good understanding of the technology of the process of pressing products from different types of polymers. He is obliged to study the equipment with which he will work, to know its device and the principle of use. He must also study what types of molds and materials exist, know their composition, properties, and where they are used. Also, his knowledge should include information about state standards and technical specifications for products manufactured by the company where he is employed.

Responsibilities

The job description of a vulcanizing presser suggests that this employee is engaged in the processing of complex polymer products. Moreover, depending on the type, special requirements may be put forward for them, including appearance, size, physical and mathematical indicators, pressing, etc. He must be able to press high thin-walled products with multiple cavities.

He is responsible for preparing equipment and accessories, including removable signs, fittings and more. The instruction of the vulcanizing presser implies that he preheats the product blanks using high-frequency current. This employee is responsible for determining and setting the pressing conditions, as well as screwing the signs that form the thread, using mechanical devices or, if possible, manually.

Rights

Since the position involves the presence of subordinate personnel,the employee has the right to give instructions to workers, control the execution of tasks and the quality of work performed. The specialist has the right to request and receive information and documents affecting him and his subordinates.

The presser-vulcanizer can interact with other company services, get acquainted with the decisions of the management and offer options for correcting the shortcomings identified in the course of the activity, if they are within his competence. He also has the right to report to the authorities about the violations found, to offer a pen alty or encouragement to the personnel subordinate to him.

Responsibility

The employee is responsible for poor quality or untimely performance of the tasks assigned to him or his subordinates. He can be held liable if he violated the company's regulations, committed violations of the current legislation and for causing material damage to the enterprise. Also, the presser-vulcanizer may be punished for failure to comply with the requirements of technological instructions, violation of fire and electrical safety rules.

He is responsible for the observance by him and his subordinates of the established order of production, labor discipline and for the breakdown of tools, equipment and other devices that are assigned to him. He can be held liable if an accident, accident or other violations occurred due to his fault or negligence.

Instructions forlabor protection for the presser-vulcanizer

Only those workers who meet age standards, in accordance with applicable law, and have undergone a medical examination confirming that they are allowed to perform this type of work, are allowed to perform work. They also need to be trained to confirm their theoretical knowledge and practical skills. Before an employee is allowed to independently perform tasks, he undergoes a mandatory internship from 2 to 14 shifts.

Their number depends on the nature of the work performed and the qualifications of the hired worker. The internship process must be supervised by another employee of the enterprise, appointed by management. Only those who have received an electrical safety group can work with power tools. Also, employees must periodically undergo a medical examination, in accordance with the procedure established by the Ministry of He alth.

Knowledge test

The presser-vulcanizer must annually pass a knowledge test on labor protection. In addition, such tests can be arranged if he has not worked for a period of more than six months or transfers to the same position in another enterprise. His knowledge can be checked if required by the company's management, state supervisory authorities and regulatory agencies. And also if new legal acts are put into effect, gross violations of labor protection have been identified or new machinery and equipment have been introduced at the enterprise.

When is the briefing?

Presser-The vulcanizer must undergo a mandatory safety briefing at the time of employment. Immediately he should be given introductory material, and then conduct an initial clarification of the norms already at the workplace. He must be re-instructed at least once every six months. It is also necessary if new or modified regulations have been introduced, the technological process, equipment, tools, raw materials or any other factors affecting labor protection have changed. It should be carried out in case of identified violations, the requirement of management or control and supervision bodies, as well as during breaks in work for more than six months.

Knowledge on labor protection

The employee is obliged to study all the passports and technical instructions of the equipment with which he will work. He must also know what danger and harmfulness exists in the workplace. The vulcanizing presser has no right to start work without knowing how to protect himself from adverse production factors, including high temperatures of materials, equipment and air, dust and dirt in the working area, as well as high noise levels.

Employee must study electrical, explosion and fire safety, be able to use fire extinguishers. The employee must use personal protection, specialized footwear and clothing when performing work. He is also required to be able to provide first aid, comply with all the rules and regulations established at the enterprise.

Occupational safety requirements

According to the instructions, the vulcanizer has no right to endanger his life and he alth, including being in those parts of the workshop that do not belong to his working environment. He must report all accidents to management in order to organize assistance to the victim, send him to a medical service point.

He is also obliged to preserve the situation, the condition of the equipment and other details until the commission arrives and investigates the incident. The only exception is when the situation could lead to an accident or threaten the lives of other workers. If an employee finds a malfunction of devices, tools or other devices, he is obliged to report this to the management and not start work until the problem is resolved. These are the basic rules and instructions for the vulcanizing presser.

They can be supplemented or modified within the framework of the current labor legislation. The basis for the change are the requirements of the company, the focus of its activities and other factors. Before starting work, the employee must familiarize himself with all management documentation and job descriptions.

Recommended:

Safety precautions for a welder during work: standards, rules and instructions

Welder is not an easy profession, but very necessary and in demand. However, we all know that this type of activity is not the safest. Today we will look at the safety precautions that professionals must follow in order to avoid accidents while working

Industrial safety engineer: job description and vacancies

There are a lot of vacancies for an industrial safety engineer on the labor market, but in order to get this job, the applicant must have certain professional and personal qualities. Employers often prefer to hire specialists with higher education

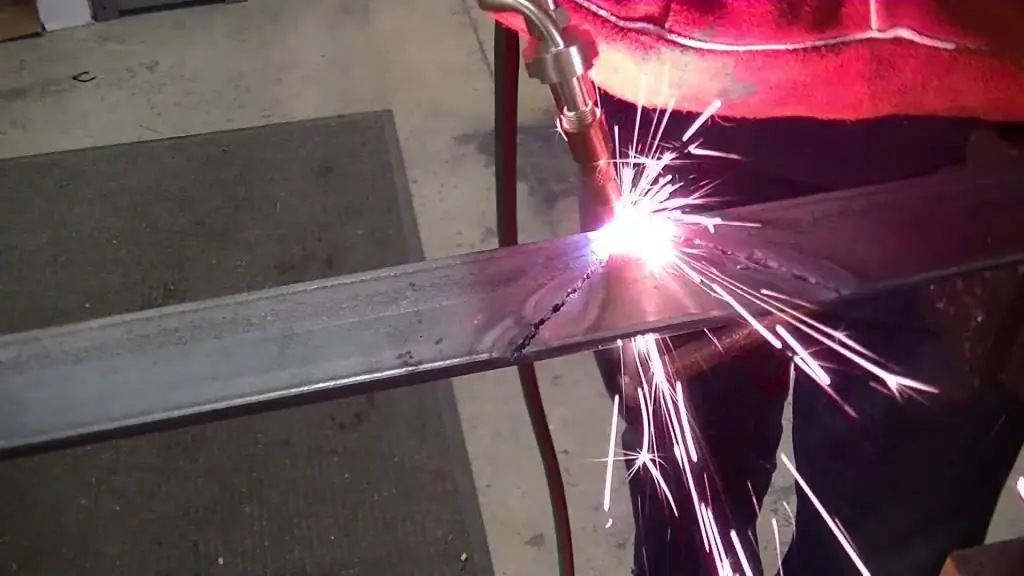

Oxyfuel cutting of metal: technology, necessary equipment, safety precautions

Oxy-fuel cutting of metals (in the literature you can find the term "oxy-fuel cutting") is actively used in industry for cutting sheet material from steel and other alloys into workpieces of the required length. The article contains information about the technology itself, about the necessary equipment and basic safety precautions for oxygen cutting of metals and other materials

Occupational safety engineer job description: basic functions

The article describes what is included in the job descriptions of an engineer for labor protection and safety at the enterprise

Occupational safety specialist: job description. Occupational Safety Specialist: Key Responsibilities

As you know, every employee in any enterprise should have their own job description. The labor protection specialist is no exception to this rule. He, like other employees, has a number of duties and functions that undoubtedly require a detailed presentation on paper