2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:26

Some believe that reinforced concrete and concrete structures are the most reliable. But this belief is wrong. Such structures are subject to destruction and damage when exposed to certain factors. This can be affected by frost, groundwater, soil deformation, rain and chemicals. Salvation in this situation is sulfate-resistant cement. It is popular in those countries where the weather dictates its laws to builders.

Cooking

This type of cement is obtained from crushed clinker, which is mixed with calcium and silicate aluminate. Particular attention in this matter is given to the dosage. Aluminate, for example, should not be contained in a volume greater than 5%, as for silicate, its volume is 50%. This ratio is not random. In nature, there are many sulfates that, when in contact with tricalcium hydroaluminate, cause sulfate corrosion. The feedstock contains the minimum amount of iron.

Application

Sulfate-resistant cement is used for concreting underground and underwater massifs. It has unique properties, therefore it is resistant to external chemical and natural factors. This cement is immune to harsh chemicals that are indispensable in construction.

In those conditions where ordinary building materials are not able to create a strong structure, the described cement helps. It has a low degree of hardening, which distinguishes it from conventional cement. Density is the main factor that determines the permanence of the work done.

State standards. Varieties. Composition

Sulfate-resistant Portland cement can have a different composition and happens:

- Slag Portland cement;

- with mineral supplements;

- pozzolanic Portland cement.

This building material is resistant to chemical and natural factors. The composition contains components that allow you to get a building that is not subject to destruction due to changeable temperature and moisture.

When choosing sulfate-resistant Portland cement, you need to familiarize yourself with the composition, because certain soil requires a certain material. The described one is created on the basis of clinker, silicate and calcium aluminate. It is widely used in the construction of hydraulic structures. Such cements are manufactured in accordance with GOST 22266-2013.

Specifications of SSPTs 400-D0

Sulfate-resistant cement SSPTs 400 DO is a type of Portland cement. It is resistant to sulfate waters. Even ordinary groundwater contains a large amount of sulfates. They contribute to the destruction of concrete. To protect concrete structures from sulphate aggression, SSPC is used.

Cement is widely used in the construction of foundations, bridge supports with a high level of groundwater. Along with certain advantages, this type of Portland cement has all the main characteristics of PC 400-D0. The compressive strength grade is mentioned in the marking and is 400 on the 28th day. Hardening speed - normally hardening. This material is made according to GOST 22266-94. The compressive strength on the third day is not standardized. At the age of 28 days, the compressive strength is 39.2 MPa. The tensile strength in bending on the 28th day is 5.4 MPa. The beginning of the setting occurs at the 45th minute, not earlier. There are no mineral additives in this cement.

Cement additives

The described product is obtained by grinding clinker of a normalized mineralogical composition and gypsum. On sale you can find Portland cement with mineral additives in the form of electrothermophosphate slag and granulated blast-furnace slag. These substances are added in a volume of 20% of the total mass. Active additives can be contained in the range from 5 to 10%. Such cement, the GOST of which was mentioned above, has a relatively low alumina modulus, as well assaturation factor.

Clinker is used for manufacturing, in which there is no more than 5% CsA and no more than 50% C3S. The total sum of C3A and C4AF must not exceed 22%. Additives for cement are C3A and C3S. In this regard, the material has a reduced heat release, since the mentioned substances are contained in a moderate amount. On sale you can find a sulfate-resistant variety marked 400. If there are mineral additives, then the brand can be 500. The compressive strength on the 28th day is 40 MPa, if there are mineral additives, then this figure rises to 50 MPa.

This material is used to create concrete structures, hydraulic structures exposed to sulfate-containing waters.

Deciphering the markings

Building cements have their own marking approved and described in SNiLS and GOSTs. The material can also be produced according to other regulatory documents. If among the first letter designations you saw PC, then you have Portland cement in front of you. Portland slag cement is abbreviated ShPCs. To understand that you have sulfate-resistant Portland cement, you can spell SPC or SSPC.

When mineral additives are present in the material, the letter D is added to the abbreviation, then the marking looks like this: SPCD. Sulphate-resistant Portland slag cement is designated by the SSSHPTs marking. If you have pozzolanic and stress cement in front of you, you will see the following letters: PPC and NC, respectively. White Portland cement andwaterproof expanding cements are designated by the letters PCB and WRC.

Cement marking and decoding is important for the consumer. So he can buy the goods he needs. After the first letters, numbers will be indicated, which in the marking look like this: ПЦ-500. This suggests that you have brand 500 cement in front of you. Other numbers and letters may follow the marking. For example, if there is a maximum content of additives in cement, then you will see: D0, D5, D20. This corresponds to a percentage of 0, 5 or 20%.

Quick-hardening cement is denoted by the letter B. Plasticizing cement is PL, hydrophobized cement is GF. Material with normalized composition of clinker - H. At the end of the marking, a regulatory document is indicated. These may be technical specifications or state standards on the basis of which the material is made.

Plasticized and hydrophobic Portland cement

Plasticized Portland cement differs from ordinary cement in its ability to impart increased mobility to concretes and mortars. This effect can be achieved by introducing clinker in a volume of 0.25%. Hydrophobizing additive is sulfide-yeast mash. It also increases the plasticity of the cement paste. Concrete structures with the addition of such cement receive a plasticizing effect, which allows to reduce the water-cement ratio and increase the density, as well as the water resistance of the structure.

Hydrophobic Portland cement is produced by introducing clinker in the amount of 0.1%, asidol, and alsosynthetic fatty acids. The composition may also contain water-repellent additives. These substances are able to reduce hygroscopicity, so cement differs from ordinary cement in that it does not deteriorate when stored in humid conditions. It does not crumple and retains its activity. Therefore, hydrophobic-type sulphate-resistant Portland cement is recommended for use in areas with high humidity. The main substance there is retained in the hardened materials and increases their water resistance, increasing resistance to external aggressive conditions.

Sulfate-resistant concrete

Today, such concrete can be obtained in two ways. The first is to add cement with special modifying agents. The 2nd technology is expressed in the preparation of a solution using sulfate-resistant cement. This method is more preferable and reliable. After all, the cement described above, the GOST of which was mentioned in the article, is able to protect the material at all stages of the life of the structure.

Concrete made using the first technology will also be protected from negative factors, but such protection can be compared with the treatment of shoes with a water-repellent composition. As for the sulfate-resistant solution, it is an analogue of rubber boots. The difference here is significant. Among other things, there is also a gradation of compression strength on the 28th day.

In closing

Sulfate-resistant Portland cement is a variation of regular Portland cement. It is resistant to sulfate waters. After all, even ordinary groundwater contains a huge amount ofsulfates. They ultimately contribute to the destruction of concrete.

In order to effectively protect concrete structures from such impacts, special-purpose cement is used. Today, it has found its wide distribution in the construction of foundations and bridge supports, which are operated at high groundwater levels.

One of its additional advantages is that it can be stored in more difficult conditions. This applies, for example, to high humidity, in which there is no clumping and caking over time.

Recommended:

Cement slurry: properties, preparation rules, composition, compliance with GOST requirements, purpose and application

During the drilling process, special solutions are used to flush out cuttings and products from the development of local rock. This operation is necessary to increase the efficiency of the mechanical impact of the drilling rig and to clear the bottom hole. Washing out is carried out using cement slurries, which are prepared using special technologies

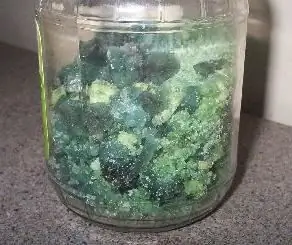

Ferrous sulfate: physical and chemical properties, production, application

Ferrous sulfate is a chemical compound that is extremely common in nature and widely used in various fields of economic activity. There are divalent and trivalent modifications of this substance. The first variety, also called ferrous sulfate, is an inorganic binary non-volatile compound having the formula FeSO4

Polymer cement mortar: composition, technical characteristics, compliance with GOST requirements, purpose and application

Polymer cement mortar is one of the modifications of conventional sand-cement mortar. Polymers can also be added to mixtures that are used when laying plaster and other facing materials. The addition of this substance to the composition helps to improve its characteristics

Aluminum (sulfate, or sulfate) - a brief description, areas of use

Aluminum sulfate (colloquial, correctly - aluminum sulfate) is a complex inorganic substance. It is white s alt with a characteristic bluish tint (let's say pink). The crystalline hydrate is colorless. Hygroscopic. Dissolves fairly quickly in water

Flux for welding: purpose, types of welding, flux composition, rules of use, GOST requirements, pros and cons of application

The quality of the weld is determined not only by the ability of the master to organize the arc correctly, but also by the special protection of the working area from external influences. The main enemy on the way to creating a strong and durable metal connection is the natural air environment. The weld is isolated from oxygen by a flux for welding, but this is not only its task