2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:30

Transmission or transformation of movement in various mechanisms and devices is carried out using gear or worm gears. This is the most common method in modern mechanical engineering and the design of various devices.

The main element of a worm or gear drive is a gear wheel. Modern engineers have not yet found a simpler and more cost-effective alternative to such a design invention. Motion converters, in which a gear wheel is involved, are reliable and durable in operation, compact and have a high efficiency. This type of transmission can transmit significant power for all its ease of use.

However, the manufacture of gears requires high precision. In case of incorrect calculations and design errors or incorrect installation of these parts, operation leads to rapid wear and tear of equipment, excessive noise and destructive vibrations.

In modern devices and mechanical engineering, various types of improved,specially treated steels, which have long established themselves as a durable, wear-resistant material. However, advanced technologies of Western and domestic manufacturers make it possible to replace metal alloys with lighter plastics and composites.

A gear wheel, in the manufacture of which textolite, polyurethane, nylon or wood-laminated plastic was used, will facilitate the design, avoid vibration or additional noise and rumble. In mechanisms where the transmission of large loads is not required, plastic will be more reliable and durable. The use of gears made of these materials will be much cheaper. And excellent anti-corrosion properties will extend the life of the part.

The classification of these elements is made depending on the location of their axes, the method of engagement, design and profile shape. There are spur, helical and herringbone gears, with external or internal gearing, bevel, cylindrical, worm and screw gears.

Each gear wheel of the mechanism can rotate both in one direction and in the opposite direction, convert the rotation of the shaft into translational motion using rack and pinion. The choice and calculation of a particular part is carried out depending on the purpose, technical characteristics and types of transmission of movement.

For the precise design of a gear, it is necessary to carry out mathematical calculations according to certain formulas, using information from normative documentation and manuals for mechanical engineering. ToThe main parameters of the part required for design include the number of teeth, the diameter of the wheel in terms of external projections and cavities, the pitch diameter of the wheel, the height of the tooth, which is the sum of the height of the head and the root of the tooth, and the engagement pitch.

When choosing a material for a gear wheel, bending strength is calculated in dangerous sections at the base and in the gearing pole of the teeth.

Recommended:

Large-caliber machine guns of Russia and the world. Comparison of heavy machine guns

Even in the First World War, a fundamentally new and terrible weapon appeared on the battlefield. Large-caliber machine guns. In those years, there was no armor that could protect against them, and the shelters that were traditionally used by the infantry (made of earth and wood) generally made their way through with heavy bullets

Wheel sets of wagons. Malfunctions of wheel sets of railway wagons

The article is devoted to malfunctions of wheelsets in railway transport. Describes common types of wear and deformation, as well as the nuances of maintenance and repair

RPK-16 machine gun: specifications. Kalashnikov light machine gun

At the international presentation of weapons "Army-2016", held in September 2016, the RPK-16 machine gun, the brainchild of domestic gunsmiths, was demonstrated. It will be discussed in this article

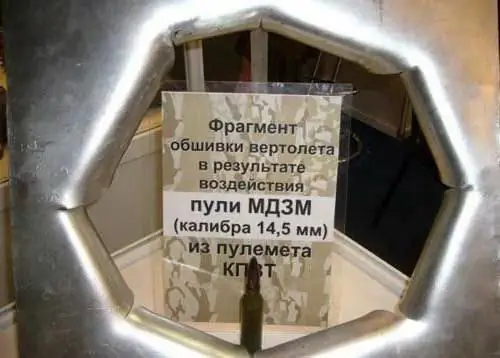

KPVT, machine gun. Heavy machine gun Vladimirov KPV

The idea of defeating aircraft and lightly armored vehicles led to the creation of heavy machine guns with a caliber of more than 12 mm. Such machine guns were already able to hit a lightly armored target, get a low-flying aircraft or helicopter, as well as shelters behind which there was infantry. According to the classification of small arms, the 14.5-mm KPVT machine gun is already adjacent to artillery weapons. And in design, heavy machine guns have much in common with automatic guns

What is the funded and insurance part of the pension? The term for the transfer of the funded part of the pension. Which part of the pension is insurance and which is funded

In Russia, the pension reform has been in effect for quite a long time, a little over a decade. Despite this, many working citizens still cannot understand what the funded and insurance part of a pension is, and, consequently, what amount of security awaits them in old age. In order to understand this issue, you need to read the information presented in the article