2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:32

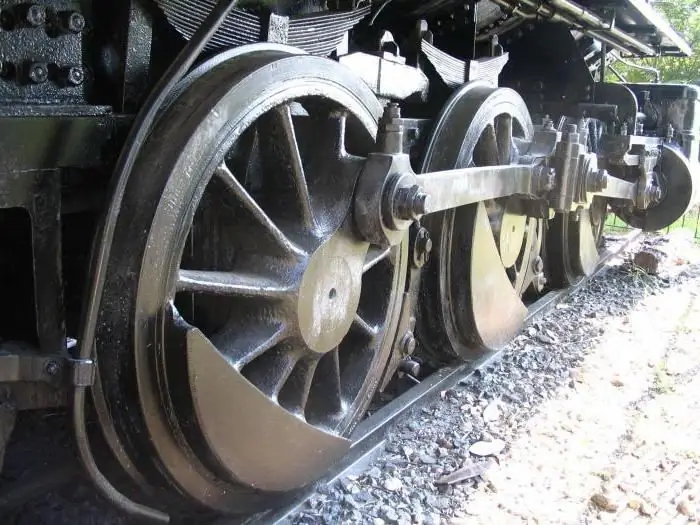

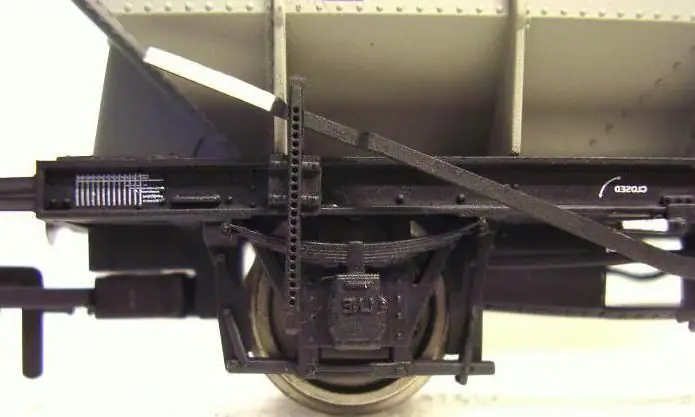

The undercarriage of railway trains includes many elements in its design, but the key of them is the wheelset. There are different versions of this component, and they differ not only in size and shape, but also in the ability to withstand various loads. In many ways, this characteristic is decisive for the working life of the chassis. Manufacturers initially endow its elements with high operational potential, but, of course, this does not guarantee the complete elimination of breakdowns and malfunctions. Regardless of the purpose and characteristics of the use of transport, the wheel sets of wagons require maintenance in good condition. By the way, elementary wear and tear is a normal phenomenon - another thing is that service personnel are required to timely detect areas close to breakdown and perform appropriate repair operations.

Causes of malfunctions

Despite the use of a robust design with high-strength metal alloys, strong dynamic and static loads can lead not only to wear, but also to deformation. The most susceptible to such phenomenawheel pairs of freight cars, since during the movement of the train there is an increased voltage in the contact zone of the rails and wheels. Therefore, in order to minimize the negative consequences of such an interaction, technologists include carbon in large proportions in the alloy. Either way, the loads can increase if the crew is traveling over a curved terrain - this generates additional stress as a result of centrifugal forces.

At the same time, one should not think that pairs for passenger trains have serious advantages in the form of low loads. In part, of course, the risks are lower in this case, but all shocks and shocks during the movement are also transmitted to the running gear, as a result of which the wheelset of the passenger car gradually wears out. It is worth noting other factors that affect the condition of the wheels. Among them are braking forces, skidding effect, unwanted contacts of the axle with the drive part, switch transitions, etc. Now you can get acquainted with the most common types of faults in more detail.

Wear of solid-rolled pairs of wheels

There are several groups of such wear. First of all, this is the formation of a uniform rolling, which the wheel sets of cars are subjected to even in normal operation. The appearance of such a deformation is due to the fact that upon contact with the rails and brake pads, a strong stress is created, which entails rolling on the surface of the wheels.

Uneven rolling is also common. It is characterized by the appearance of deformation zones notover the entire area of the contact zone, but only in certain axes. This indicates that the wheelsets of the wagons were manufactured with an uneven distribution of properties over the entire mass of the alloy. That is, the appearance of such a rolling testifies, first of all, to marriage in the couples themselves. Next, it is worth noting the circular influx. It can be observed outside the contact rim of the wheel when the mass moves away on the sides of the chamfer.

Tread wear

Deformation of this kind also occurs in the area of the contact zone. A feature of wear is that it occurs when skidding. Therefore, the deformation of the rolling surfaces is often associated with violations in the operation of the brake pads. Visually, such malfunctions of wheel sets appear in the form of a slider - this is a flat area on a white metal surface. Despite the fact that during operation such defects do not cause serious problems, they can turn into troubles of another kind.

The fact is that in the places of the slider there is almost always an increased formation of heat, which is transmitted deep into the wheel rim. As a result, the so-called dents are formed, which entail a specific color in the place of the roll. Over time, the wheelset begins to react sensitively to any irregularities in the "canvas", which leads to the appearance of shocks in the chassis. Therefore, if sliders larger than 1 mm are detected, then serious restrictions are imposed on the speed of the train. By the way, the wheelset of a diesel locomotive and a freight car are most susceptible to such deformation. It is noteworthy that the intensity of the formation of a creeper also depends on the season - for example, in winter and early spring, the risks of its formation are higher.

Axis failures

Faults in the necks and pre-hub parts are expressed as undersized axles. There may be several reasons for this. First of all, deformation occurs due to an insufficiently strong connection and in cases where the cleaning of metal surfaces from rust formations was incorrectly performed. Also, the axle of the wheelset is often subjected to fractures and cracks in places with the highest loads. Such processes arise due to cyclic stress, the presence of sections with transitional sections, and the discontinuity of the metal itself. Of course, the usual failures in the form of insufficiently strong fastenings of bolts and nuts are not excluded.

Metal build-up

This is a damage of a thermomechanical nature that affects the wheel sets of cars in the rolling surfaces. During inspections, such deformations fix the shear zones of the material with a U-shape. In essence, this is a kind of plastic deformation processes. The maximum shift falls on the central part of the contact strip. In turn, the minimum shift can be found at the edges. The reason for this damage is the distribution of loads with pressure on the contact area.

General wheel maintenance measures

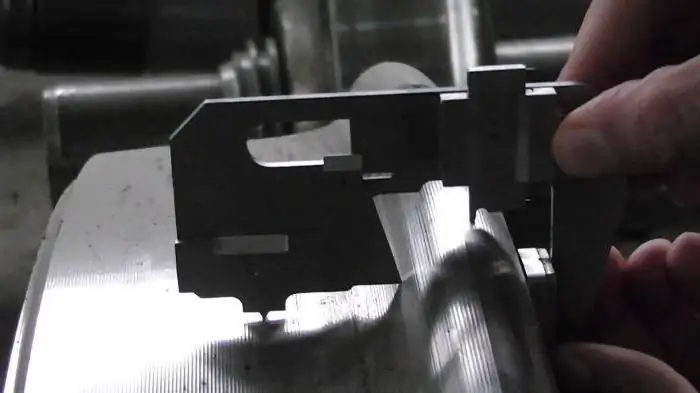

Preventive measures help prolong the life of your wheels. Maintenanceprovides for inspection, certification, indications for repair operations, etc. If we talk about technical measures, then the main one will be the correct turning of wheel sets with a minimum layer of metal removal. The number of turnings is reduced due to special measures aimed at improving the reliability of the wheelsets and eliminating existing weaknesses in the undercarriage. In particular, specialists seek to eliminate force factors that occur during operation and appear due to previously occurring defects. For example, malfunctions in the spring-spring part, which affect the quality of the running base, are eliminated.

Repair and recovery operations

Repair operations are carried out in a special mechanical area after the elements have been thoroughly washed. In a special department, wheel changes, turning or welding events are carried out. If it is planned to repair wheel sets in order to change the profile of the elements, then the work is carried out using special templates. It should be noted that the permissible deviation in the parameters of the wheels from the template is 1 mm along the ridge height, and 0.5 mm along the inner edges and the skating area. As already noted, electric welding operations can be used in repairs. Such equipment is used for cutting axial threads and surfacing center holes.

Conclusion

There are special regulations that describe in detail the malfunctions of wheel sets, as well as methods and technologies for their elimination andprevention. It is important to note that the undercarriage as a whole is affected by many factors of mechanical properties. As a result, the performance and service life of the wheelset depend not only on the quality of the tracks, but also on the brake system, the spring-spring unit, the mode of movement of the crew, and even the time of year.

Recommended:

Railway station. RZD: map. Railway stations and nodes

Railway stations and junctions are complex technological facilities. These elements form a single track network. Later in the article we will consider these concepts in more detail

Axlebox units: description, malfunctions, design and repair

Currently, railway communication within the country and between countries is quite well developed. The fact that trains carry a large number of people or valuable goods suggests that they must always be in perfect technical condition in order to avoid huge problems. One of the most important elements is the axle box

Wagons: types of wagons. Classification of cars in Russian Railways trains

Types of passenger and freight cars, as well as subway cars. Features, description and application of each type of wagons and tanks

Generator sets: diesel power plant. Characteristics, maintenance, repair

The article is about diesel generator sets. The characteristics of such equipment, the nuances of maintenance and repair are considered

Malfunctions and repair of hydraulic carts: features, device and recommendations

Of course, the operation of any device leads to the fact that it gradually fails. Some parts break, grease dries out, etc. All this also applies to hydraulic carts, the repair of which is quite simple, but you need to know how and when to carry it out