2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:30

Modern industry cannot be imagined without such material as steel. We encounter it at almost every turn. By introducing various chemical elements into its composition, mechanical and operational properties can be significantly improved.

What is steel

Steel is an alloy that contains carbon and iron. Also, such an alloy (photo below) may have impurities of other chemical elements.

There are several structural states. If the carbon content is in the range of 0.025-0.8%, then these steels are called hypoeutectoid and have pearlite and ferrite in their structure. If the steel is hypereutectoid, then pearlitic and cementite phases can be observed. A feature of the ferrite structure is its high plasticity. Cementite also has considerable hardness. Perlite form both previous phases. It can have a granular shape (inclusions of cementite are located along the grains of ferrite, which have a round shape) and lamellar (both phases look like plates). If steel is heated above the temperature at whichpolymorphic modifications occur, the structure changes to austenitic. This phase has increased plasticity. If the carbon content exceeds 2.14%, then such materials and alloys are called cast irons.

Types of steel

Depending on the composition, steel can be carbon and alloyed. The carbon content less than 0.25% characterizes mild steel. If its amount reaches 0.55%, then we can talk about a medium-carbon alloy. Steel that has more than 0.6% carbon in its composition is called high-carbon steel. If, in the process of producing an alloy, the technology involves the introduction of specific chemical elements, then this steel is called alloyed. The introduction of various components significantly changes its properties. If their number does not exceed 4%, then the alloy is low-alloyed. Medium-alloyed and high-alloyed steel has up to 11% and more than 12% of inclusions, respectively. Depending on the area in which steel alloys are used, there are such types of them: tool, structural and special steels and alloys.

Production technology

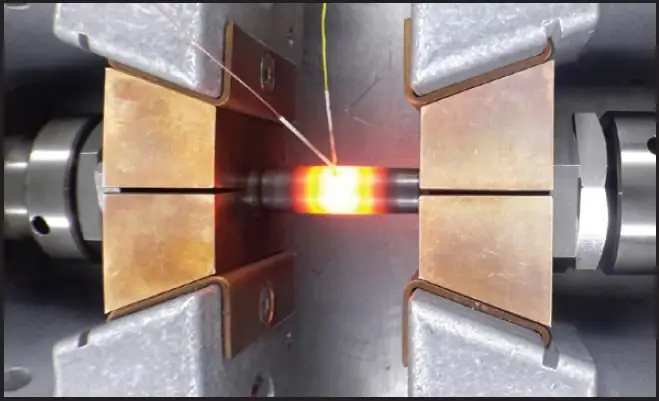

The process of smelting steel is quite laborious. It includes several stages. First of all, you need raw materials - iron ore. The first stage involves heating to a certain temperature. In this case, oxidative processes occur. In the second stage, the temperature becomes much higher. The processes of carbon oxidation are more intensive. Additional enrichment of the alloy with oxygen is possible. Unnecessary impurities are removed inslag. The next step is to remove oxygen from the steel, as it significantly reduces the mechanical properties. This can be carried out in a diffusion or precipitating manner. If the deoxidation process does not occur, then the resulting steel is called boiling steel. Calm alloy does not emit gases, oxygen is removed completely. An intermediate position is occupied by semi-quiet steels. The production of iron alloys takes place in open-hearth, induction furnaces, oxygen converters.

Steel alloying

In order to obtain certain properties of steel, special alloying substances are introduced into its composition. The main advantages of this alloy are increased resistance to various deformations, the reliability of parts and other structural elements increases significantly. Hardening reduces the percentage of cracks and other defects. Often this method of saturation with different elements is used to impart resistance to chemical corrosion. But there are also a number of disadvantages. They require additional processing, there is a high probability of the appearance of flocs. In addition, the cost of the material also increases. The most common alloying elements are chromium, nickel, tungsten, molybdenum, cob alt. The scope of their application is quite large. This includes mechanical engineering, and the manufacture of parts for pipelines, power plants, aviation and much more.

The concept of heat resistance and heat resistance

The concept of heat resistance refers to the ability of a metal or alloy to retain all of its characteristics when working at high temperatures. In such an environment, oftengas corrosion is observed. Therefore, the material must also be resistant to its action, that is, be heat-resistant. Thus, the characterization of alloys that are used at significant temperatures must include both of these concepts. Only then will such steels provide the necessary service life for parts, tools and other structural elements.

Features of Heat Resistant Steel

In cases where the temperature reaches high values, the use of alloys is required that will not collapse and succumb to deformation. In this case, heat-resistant alloys are used. The operating temperature for such materials is above 500ºС. Important points that characterize such steels are high endurance limit, plasticity, which persists for a long time, as well as relaxation stability. There are a number of elements that can significantly increase resistance to high temperatures: cob alt, tungsten, molybdenum. Chromium is also a required component. It does not so much affect the strength as it increases the scale resistance. Chromium also prevents corrosion processes. Another important characteristic of alloys of this type is slow creep.

Classification of heat-resistant steels by structure

Heat-resistant and heat-resistant alloys are of the ferritic class, martensitic, austenitic and with a ferritic-martensitic structure. The former contain about 30% chromium. After special processing, the structure becomes fine-grained. If the heating temperature exceeds 850ºС, then the grainsincrease, and such heat-resistant materials become brittle. The martensitic class is characterized by the following chromium content: from 4% to 12%. Nickel, tungsten and other elements may also be present in small amounts. Parts of turbines and valves in automobiles are made from them. Steels that have martensite and ferrite in their structure are suitable for operation at constant high temperatures and long-term operation. The chromium content reaches 14%. Austenite is obtained by introducing nickel into heat-resistant alloys. Steels with a similar structure have many grades.

Nickel based alloys

Nickel has a number of useful properties. It has a positive effect on the workability of steel (both hot and cold). If a part or tool is designed to work in an aggressive environment, then alloying with this element significantly increases corrosion resistance. Nickel-based heat-resistant materials are divided into the following groups: heat-resistant and actually heat-resistant. The latter should also have minimum heat-resistant characteristics. Working temperatures reach 1200ºС. Additionally, chromium or titanium is added. Characteristically, nickel-alloyed steels have a small amount of impurities such as barium, magnesium, boron, so the grain boundaries are more strengthened. Heat-resistant alloys of this type are produced in the form of forgings and rolled products. It is also possible to cast parts. Their main area of application is the manufacture of gas turbine elements. Nickel-based heat-resistant alloys contain up to 30% chromium. They lend themselves well enough to stamping, welding. In addition, the scale resistance is at a high level. This makes it possible to use them in gas pipeline systems.

Heat-resistant titanium alloy steel

Titanium is introduced in a small amount (up to 0.3%). In this case, it increases the strength of the alloy. If its content is much higher, then some mechanical properties deteriorate (hardness, strength). But the plasticity increases. This facilitates the processing of steel. With the introduction of titanium together with other components, it is possible to significantly improve the heat-resistant characteristics. If there is a need to work in an aggressive environment (especially when the design involves welding), then alloying with this chemical element is justified.

Cob alt alloys

A large amount of cob alt (up to 80%) goes to the production of materials such as heat-resistant and heat-resistant alloys, since it is rarely used in its pure form. Its introduction increases plasticity, as well as resistance when working at high temperatures. And the higher it is, the higher the amount of cob alt introduced into the alloy. In some brands, its content reaches 30%. Another characteristic feature of such steels is the improvement in magnetic properties. However, due to the high cost of cob alt, its use is rather limited.

Influence of molybdenum on heat-resistant alloys

This chemical element significantly affects the strength of the material at high temperatures.

It is especially effective when used together with other elements. It significantly increases the hardness of steel (already at a content of 0.3%). The tensile strength also increases. Another positive feature that heat-resistant alloys alloyed with molybdenum have is a high degree of resistance to oxidative processes. Molybdenum contributes to the grinding of grain. The disadvantage is the difficulty of welding.

Other special steels and alloys

To perform certain tasks, materials are required that have certain properties. Thus, we can talk about the use of special alloys, which can be both alloyed and carbon. In the latter, the set of required characteristics is achieved due to the fact that the manufacture of alloys and their processing takes place using a special technology. Even special alloys and steels are divided into structural and tool. Among the main tasks for this type of materials, the following can be distinguished: resistance to corrosion and wear processes, the ability to work in an aggressive environment, and improved mechanical characteristics. This category includes both heat-resistant steels and alloys with high operating temperatures, and cryogenic steels that can withstand up to -296ºС.

Tool steel

Special tool steel is used in the production of tools. Due to the fact that their working conditions are different, materials are also selected individually. Since the requirements for tools are quite high, the characteristics of alloys for theirproduction is appropriate: they must be free of third-party impurities, inclusions, the deoxidation process is well carried out, and the structure is homogeneous. It is very important for measuring instruments to have stable parameters and resist wear. If we talk about cutting tools, then they work at elevated temperatures (there is heating of the edge), constant friction and deformation. Therefore, it is very important for them to maintain their primary hardness when heated. Another type of tool steel is high speed steel. Basically, it is doped with tungsten. Hardness is maintained up to a temperature of about 600ºС. There are also die steels. They are designed for both hot and cold forming.

Special Alloy Applications

Industries that use alloys with special characteristics are many. Due to their improved qualities, they are indispensable in mechanical engineering, construction, and the oil industry. Heat-resistant and heat-resistant alloys are used in the manufacture of turbine parts, spare parts for cars. Steels that have high anti-corrosion characteristics are indispensable for the production of pipes, carburetor needles, disks, and various elements of the chemical industry. Railroad rails, buckets, tracks for vehicles - wear-resistant steels are the basis for all this. In the mass production of bolts, nuts and other similar parts, automatic alloys are used. The springs must be sufficiently elastic and wear-resistant. That's whymaterial for them is spring steel. To improve this quality, they are additionally alloyed with chromium, molybdenum. All special alloys and steels with a set of specific characteristics can reduce the cost of parts where non-ferrous metals were previously used.

Recommended:

How profitable is it to use a credit card? Overview of credit cards and terms of use

The decision to issue a credit card comes to the client within a few minutes after sending the application for receipt. If approved, issuing a card can take up to three days, some financial institutions issue them to customers immediately upon application. A borrower over the age of 18, in order to issue a credit card to him, must provide a banking organization with his passport data, documents confirming income (certificate 2 personal income tax)

Heat energy tariff: calculation and regulation. Heat energy meter

Who approves and regulates heat tariffs? The main factors affecting the cost of the service, specific figures, the trend of increasing cost. Thermal energy meters and self-calculation of the cost of the service. Prospects for billing. Varieties of tariffs for organizations and citizens. Calculation of REC tariffs, documentation required for this

Heat resistance and heat resistance are important characteristics of steels

Ordinary structural steels, when heated, abruptly change their mechanical and physical properties, begin to actively oxidize and form scale, which is completely unacceptable and creates a threat of failure of the entire assembly, and possibly a serious accident. To work at elevated temperatures, materials engineers, with the help of metallurgists, created a number of special steels and alloys. This article gives a brief description of them

Types of heat transfer: heat transfer coefficient

Because the heat of different substances may differ, there is a process of transferring heat from a hotter substance to a substance with less heat. This process is called heat transfer. We will consider the main types of heat transfer and the mechanisms of their action in this article

Heat treatment of alloys. Types of heat treatment

Heat treatment of alloys is an integral part of the production process of ferrous and non-ferrous metallurgy. As a result of this procedure, metals are able to change their characteristics to the required values. In this article, we will consider the main types of heat treatment used in modern industry