2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

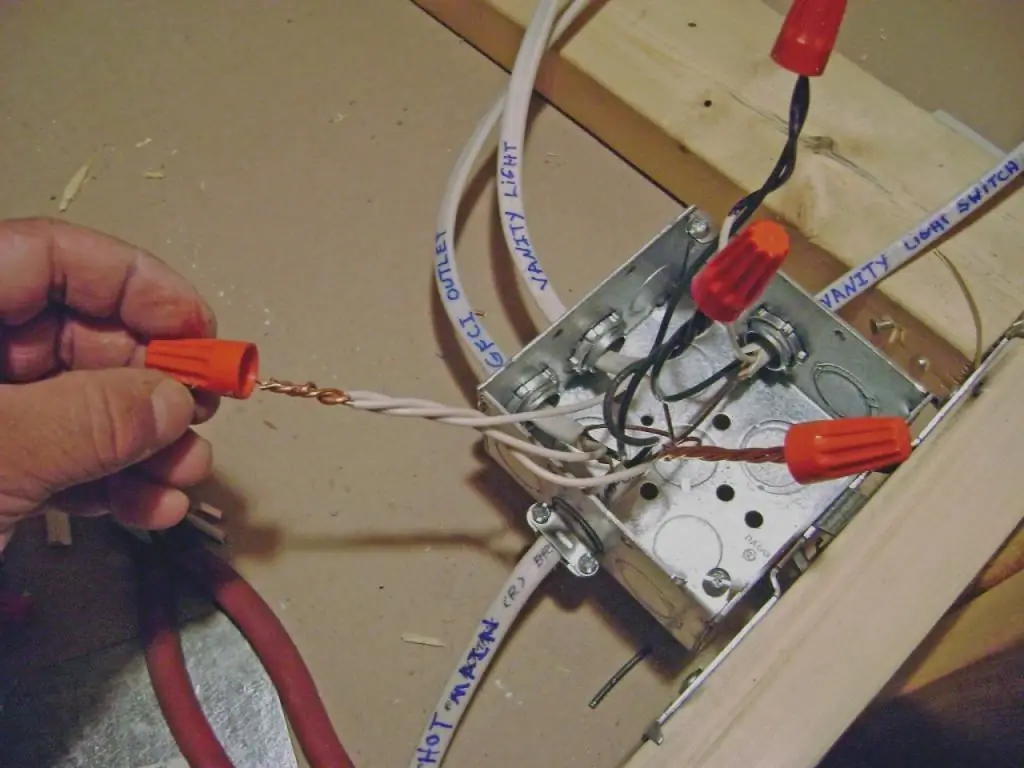

In the process of repair, the owners of a house or apartment are faced with the need to install junction boxes. The wires in them must be properly mounted. The most famous way in this case is twisting. It has certain advantages and disadvantages. Almost everyone can do the twisting in the junction box with their own hands. But at the same time, you need to learn about all the nuances of such work. How to twist will be discussed later.

Where to start?

One of the oldest ways to connect electrics is to twist wires in a junction box. How to perform such a procedure correctly? Before embarking on such a task, you need to consider all the features of this process.

You need to understand that an incorrectly made connection poses a potential threat to the residents of the house, their neighbors. Previously, twisting was the only way to connect wires. But over time, this technology has improved. People began to use more electrical appliances that have high power. Therefore, significant loads are acting on the electrical system today. Normal twisting, unfortunately, cannot withstand such exposure.

It must be remembered that the connection of wires in the junction box according to the PUE cannot be done using ordinary twisting. During the construction or reconstruction process, it is impossible to put into operation an object that has wires in this structure connected in the presented way.

However, twisting does not lose its relevance today. Its improved versions are used. The usual one is used by home craftsmen when connecting wires with a slight load. The connection is the weak point of the entire electrical system, so it must be done correctly. The consequences of a negligent attitude to the requirements of the PUE will be not only a possible electric shock to users of the power grid, but also the possibility of a fire. In this case, the unlawful actions of the owners of the house or apartment may become a reason for bringing them to criminal liability. To prevent this from happening, you need to do all the work on connecting electricians correctly.

Common mistakes

Before starting work, you need to familiarize yourself with the established requirementsregarding the twisting of wires in the junction box according to the PUE. This will avoid mistakes. A novice electrician should study all the requirements that are put forward by such rules for making connections.

Some masters neglect the requirements for personal safety. They use an unsuitable tool that is not protected against electric shock. It is also important to work in rubberized shoes, turning off the power in the apartment or house. These are simple rules to follow as you work.

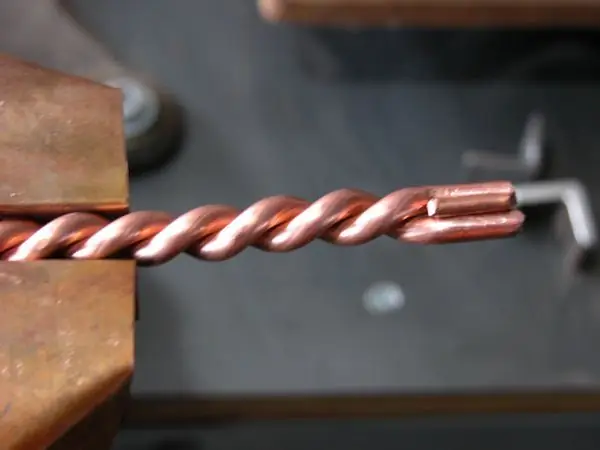

Twisting electrical wires in the junction box must be done according to the established methodology. It is unacceptable to wind one wire onto another. This mistake is often made by novice electricians. The cores must necessarily be wound evenly one on top of the other. Only in this case can the entanglement guarantee sufficient mechanical strength of such a connection. The current in this case will pass through the conductor correctly. Such a connection, if properly maintained, will last for many years.

Many masters make a mistake when choosing the length of the twist. Its size must comply with the requirements of the instructions. A connection that is too short breaks easily. There is a certain relationship between the length of the twist and the thickness of the wire. The thinner it is, the shorter the connection can be. Thick strands require a long twist.

Varieties

How to twist wires in a junction box? For this, several methods are used. By doing them correctly, you can create a high-quality connection that will be safely operated for several decades.

It is worth adhering to a simple rule, which says that only wires of the same type can be connected using twisting. If they are different, you will need to use special terminals, clamps. Electricians most often use the following types of twisting:

- simple;

- groove twist;

- bandage.

The above methods can be applied in parallel, in series or with a branch. Each subspecies has its own characteristics. So, a simple method of connecting wires using twisting is widely used by home craftsmen to make connections in a junction box. However, to increase its reliability, additional elements are used, for example, special caps.

If it is necessary to connect large diameter cores, a bandage twist is used. The groove technique is mainly used for aluminum wire. It is very important to make such a connection with a great degree of accuracy.

It is worth noting that the twisting of wires in the junction box using the presented methods is used only if the cross section of the wires does not exceed 10 mm². Typically, in domestic conditions, wires with a cross section of 1.5 or 2.5 mm² are used.

When twisting is unacceptable

In some cases it is unacceptable to use the twisted wires in the junction box. Howmake the connection correctly, as indicated in the PUE. Of course, regardless of the requirements of the standards, twisting remains the most popular type of connection. Both professional and novice masters will not refuse it.

But it should be remembered that over time, this fixation gradually weakens. This is due to the residual elastic deformation of the cores. At the attachment point, the contact resistance increases, which leads to overheating of the wire. In this case, the connection is broken. Only a well-executed twist will last a long time.

In some situations, due to the peculiarities of such a connection, one cannot even think about using it when connecting. Such a limitation may be the current in the electrical circuit, which exceeds 3 A. It is also strictly excluded to use the presented type of connection if the box is in combustible material.

If the master is a professional electrician, he is also prohibited from using this switching method. Otherwise, he will be liable, up to criminal punishment. The master connecting the wires using the presented technique exposes customers to potential risk. If a fire occurs (which is not uncommon when using a twist), the blame lies entirely with the electrician. Therefore, masters today avoid using this method in the performance of their professional duties.

Simple twist

If, for example, you need to twist copper wires in a junction box, which areof the same type, you can use the following instructions. It is necessary to turn off the voltage in the network. Next, both cores must be cleaned with high quality. But at the same time, you need to act carefully so as not to damage the core.

The length of the twisted wires in the junction box can be different. But 5 cm is considered the standard. This is enough to create a strong connection on wires of 2.5 mm².

You can use a special tool for twisting wires in the junction box. With it, it is easy to strip the insulation from the wire without damaging it. After that, the exposed contacts must be wiped with a cloth soaked in acetone. After degreasing the surface, you need to clean the ends with sandpaper. Processing is carried out until a metallic color appears.

First, the strands are crossed, and then they are twisted with pliers. You need to act carefully so that the turns are uniform. You should get at least 5 turns. The finished twist is isolated. For this, electrical tape is used. It is better to use heat shrink tubing instead. They are also called cambric. Such materials will qualitatively protect the junction from the adverse effects of the environment. If you follow all the steps in accordance with the instructions, you can get a secure fixation of the wires. This method is best used for copper wire.

Twisting solid and stranded wires

The more difficult task is to fix the solid and stranded wire. In this case, it is also recommended to resort to a different method. But if there is no other way out, then it is possibletwisting in a junction box 6 wires of stranded type with a single-core cable. You need to act according to the instructions, without neglecting any stage of the work.

First, the wires are exposed using a special tool. If not, you can use a knife, but you need to be careful. The length of the bare core should be at least 5 cm. Next, the ends of a single or stranded wire are treated with acetone and sandpaper.

When the preparatory work is done, the two wires are crossed and at a distance of 2.5 cm from the edge, the stranded wire is started to be wound.

Considering the method of how to twist wires in a junction box, it is worth paying attention to the winding process. All thin cores must lie flat on the monocore. Further, with the help of pliers, the free end must be bent towards the turns. A single-core wire will tightly press the section on which the stranded one is wound. The connection is insulated with cambric.

The same technique is used if you need to fix two stranded wires. It is worth remembering that it is impossible to connect aluminum and copper conductors. Such an action will lead to the rapid destruction of the junction. As a result, a short circuit will occur, the wire will overheat. This could start a fire. Therefore, only identical materials should be combined.

Pro Tips

Experts give advice on how to twist wires in a junction box. If the owners of the house are allwe decided to choose this particular technique for connecting the cable cores, it is best to additionally solder or weld the attachment point. This will greatly increase the security of the connection. It will become inseparable, and therefore reliable. If the conductors have a large cross-sectional diameter, the application of the additional steps presented is mandatory.

Experts advise using Wago terminals when connecting wires. This will greatly simplify the mounting process, as well as make the operation of the electrical system safe. With the help of such devices for twisting wires in a junction box, you can switch cables made of copper and aluminum, conductors of different sections.

Another reliable fixation method is the use of PPE clips. These are inexpensive devices that increase the security of the connection several times. Don't skimp on your own safety. Modern fixtures are affordable. They provide a high level of security.

If the fixation was done by twisting, do not immediately hide the wires in the box. You need to turn on the network, and then electrical appliances. For several hours, at maximum load on the line, it is necessary to observe the place of twisting. Only if everything is in order with him, you can install them in the place intended for this. If the mount gets hot, you need to redo the job again. This means that the junction turned out to be unreliable.

Soldering or welding

Twisting wires in a junction box will be reliable if it is soldered or welded. For this you need to usespecial tools and materials. After cleaning the ends, they are twisted. Actions are similar to a simple twist. But after creating such a connection, the twisted ends are dipped into pre-molten solder. The cores are then lowered into the solder bath. When the material cools down, you need to additionally protect the attachment point with a cambric. You can also use electrical tape.

It is also acceptable to use a soldering iron. But this method is almost impossible to apply if you need to solder 3-4 cores with a standard cross section (2.5 mm²). In this case, soldering is possible only if the tool has a thick copper tip. It must have a high heat capacity. The power of the soldering iron must be at least 40W (60W is better).

It is worth noting that it is strictly forbidden to cool the fixation site when using the cold water soldering method. Fastening in this case will turn out to be of poor quality. Microcracks appear in the material due to a sharp temperature drop.

Advantages and disadvantages

The twisting of wires in the junction box, reinforced by soldering, has high reliability and quality of the fixation point. But this technique also has certain drawbacks. You need to know about them before starting work.

The disadvantage of soldering is the need to purchase a special tool that you need to be able to handle correctly. The fixing process in this case is very laborious. The end result is ultimately indestructible. To disconnect the wires, they will need to be cut. This shortens the conductors.

EICs also limit the application of this approach to residential premises. In combustible materials, the use of this type of connection is unacceptable. Over time, the soldering point loses voltage, and the electrical conductivity decreases.

Using a screwdriver

Using a screwdriver, you can create a uniform twist. In this case, no additional devices are required. The wires are prepared for the connection. The ends of the cable are bent and installed in the screwdriver chuck. He needs to be clamped down. Next, you need to click on the tool button. Turnovers should be set small. The wire must be held with pliers. When the twist is completed, the ends are cut off. Then you can isolate the twist with a cambric or electrical tape. But it is better to further strengthen the connection with soldering. The screwdriver ensures uniform winding of wires on top of each other. This improves the quality of the connection.

Recommended:

How to pay off a credit card: step by step instructions, ways and methods, tips

Today, there are practically no people left who have never encountered credit cards. For many, they turn out to be evil, but this is because people do not know how to use them correctly. You also need to be able to pay off credit cards, which we will teach in this article

How to get Sberbank card details at an ATM: step by step instructions, tips and tricks

Wishing to transfer wages to a Sberbank card, customers often ask themselves what is required for this? In order for an employer or an individual to transfer funds to a plastic card, you must provide its details. You can recognize them by your passport at the bank office, but for this you will have to stand in line. It is much faster to look at the information in one of the thousands of terminals of the company. To do this, you need to have an idea of u200bu200bhow to get the details of a Sberbank card at an ATM

What is a safe deposit box? Is it worth renting a deposit box?

We continue to understand popular banking services. This article will discuss the rental of deposit boxes. You can also find answers to frequently asked questions and tips on choosing the right bank to trust your valuables

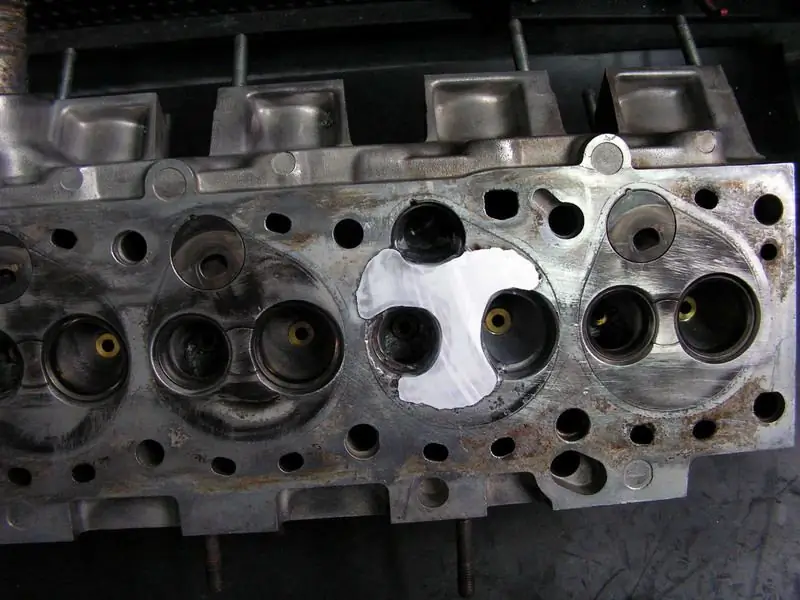

Repair of the engine block: step-by-step instructions with a description, device, principle of operation, tips from the masters

The block is the main part of almost any internal combustion engine. It is to the cylinder block (hereinafter referred to as the BC) that all other parts are attached, starting from the crankshaft and ending with the head. BCs are now made mainly of aluminum, and earlier, in older car models, they were cast iron. Cylinder block failures are by no means uncommon. Therefore, it will be interesting for novice car owners to learn how to repair this unit

Welding wires in a junction box: step by step instructions, rules, tips and tricks

Features of welding wires in a junction box with your own hands. The main advantages of the welding connection of wires and the technology of the welding process. Electrodes that are used in the welding of copper conductors. Apparatus for welding. DIY step-by-step instructions for making a welding machine