2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

The root cause of the birth of the mechanism was the need to irrigate the fields of the ancient farmers of Egypt, Mesopotamia, China, India. It is known that farmers in these countries have long been forced to artificially water their crops. And then a way was found with the help of primitive devices to organize the transportation of water. They were called differently in different countries, but the principle was the same. A little later, with the invention of the wheel, people learned to use the power of water for such work.

In the days of Ancient Greece and the Roman Empire, mills, water pipes, and other mechanisms were set in motion with the help of slaves, and later with the help of animals.

Stages of cultivation

But the proper conveyor belts, familiar to us and intended for industrial use, appeared only in the 18th century. At first, a board served as the basis for them, along which a ribbon of leather or canvas moved. In 1908, Heiml Goddard patented the roller base for conveyors. But the real "parent" of the conveyor belt was Henry Ford,who noticed that workers were wasting too much time getting parts to the job site and installed conveyor belts that moved parts from one shop to another. This contributed to the increase in labor productivity, reduced the cost of production and became the starting point in the development of conveyors.

Over time, the mechanisms for moving goods became more and more perfect. Belt conveyors received a new round of development with the development of industrial development of various deposits (during the extraction of gold, coal, ores).

Types and scope

Today, the variety of types of conveyors is amazing. With the help of them we receive things at the airport, bread and confectionery factories work, newspapers are printed, cars are assembled, coal is lifted from mines and rock is moved over long distances from quarries.

The use of conveyors saves time, allows you to optimize the production process and get rid of heavy manual labor.

Its device, in comparison with other lifting mechanisms, is quite simple, it is easy to repair and operate. The main components of the conveyor are:

- supports (stationary or adapted for movement);

- drive belt conveyor, which consists of an electric motor, gearbox (cylindrical, worm, chain or belt drive, or gear belt) and drive drum;

- supporting surface (rollers or metal sheet);

- bearing body - conveyortape;

- tension mechanism (drum and screw).

To move various materials, several types of belt conveyors were invented:

- tape;

- lamellar;

- inertial;

- vibrating;

- roller;

- scraper;

- suspended load carriers;

- pushing;

- trolley;

- bucket and cradle;

- screw.

Some of them have a special purpose, for example, for the transport of passengers (escalators). The direction of movement of goods can be any - horizontal, inclined, vertical.

Truly, the belt conveyor has the status of the most popular mechanism for moving almost any material. Modern electronics and automation increase its capabilities many times over.

Recommended:

Toothed belt. Timing belt profiles

The belt drive, which uses a toothed belt, is one of the oldest mechanical inventions. However, despite the fact that this transmission method was invented a very long time ago, it is actively used at the present time

Belt conveyor: work, scheme and device. Operation of belt conveyors

Today it is difficult to imagine high-performance production without the use of a conveyor. To move goods, including bulk, use closed belts. We can say that this is a continuous unit, which has a load-bearing body (flexible tape). Let's take a closer look at what a belt conveyor is, what is its purpose, scope, and also what are the subtleties of operating this equipment

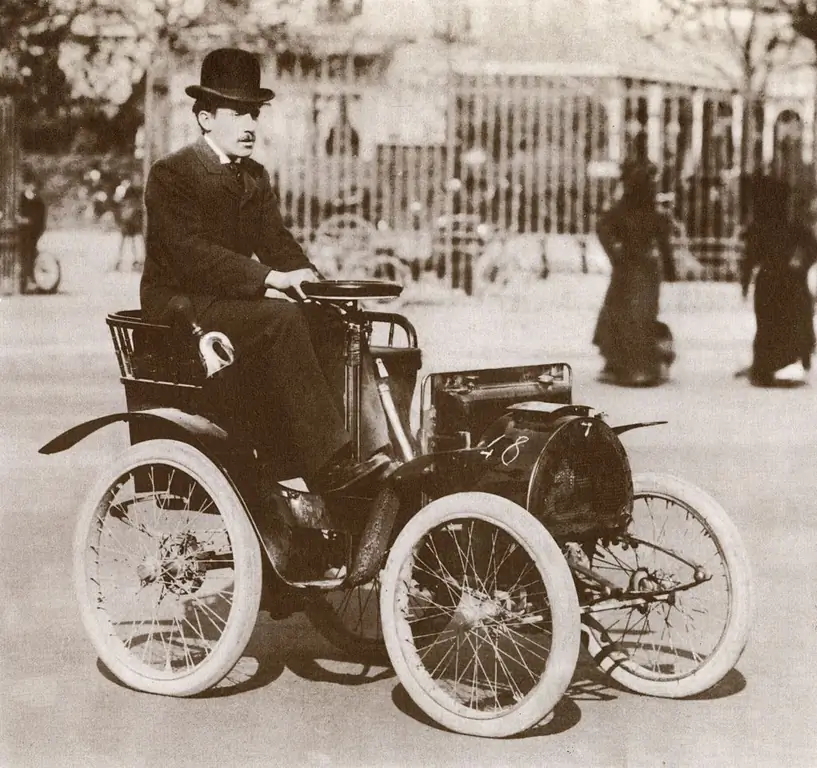

"Renault": manufacturer, history and date of creation, management, country, technical focus, development stages, introduction of modern technologies and car quality

The Renault manufacturer produces high-quality cars that are in demand in many countries of the world. The products were to the taste of Russian motorists. In 2015, the French concern produced the millionth car from the lines of the Russian plant

Vitamin plant in Ufa: history and date of establishment, management, addresses, technical focus, stages of development, introduction of modern technologies and product quality

The life of a modern person takes place in a rather unfavorable ecological environment, accompanied by intellectual and emotional overload. You can't do without taking vitamins and minerals even in the summer. This material will focus on one of the oldest enterprises in Ufa, which is engaged in the production of useful products

Irkutsk heavy engineering plant: history and date of establishment, address, management, technical focus, stages of development, introduction of modern technologies and quality

Irkutsk heavy engineering plant is a city-forming enterprise producing equipment for leading industries in Russia. The company's products are supplied to the domestic market, finds recognition and demand abroad