2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:32

The rolling mill as a device for processing metals and other materials by the pressure of several rotating rolls was first mentioned in the works of Leonardo da Vinci. The oldest mechanism, described by the great master in 1495, was intended for processing tin. Rolling devices were already quite widely used in the 17th century, where they worked on the basis of manual drives, which were later replaced by water (water wheel), and then by steam. Today, hand-operated rental equipment is often used for handicraft work.

The rolling mill as part of its equipment has the main part (working stand, which can accommodate from two to several rolls, electric motors and devices that transmit energy to the rolls from the engines) and auxiliary (equipment for moving billets, cutting them, editing, edging, etc.). The design of specific equipment is tied to the type of product it produces.

Rental productsaccording to the type of cross section is divided into several groups, including:

- pipes (seamless or welded);

- sheet products (thin sheets or thick sheets (more than 4 mm));

- long products (shaped or plain);

- special rolled products (corner, C-shaped, variable profile, etc.).

Rolling mill by type of product can be assigned to one of the following groups: pipe, tape, tin rolling, special, sheet, wire, strip, broadband, section, swaging (mainly blooming), billet, rail and beam mills. This type of equipment is large. For example, a mill considered small might be fifteen meters long, while the largest mill to date is 5,500 meters long (owned by Anshen Iron And Steel Group).

Classification of rolling mills by design features is as follows:

- single-cage (they include a cage, supplemented, for example, with six electric motors, five clutches, four gearboxes, three gear cages and two spindles);

- linear mills (stands are located one after another, sometimes in several lines, products are processed in one direction);

- sequential (several single-stand mills are arranged in series or in a different order);

- continuous (the workpiece is processed simultaneously in a number of stands);

- semi-continuous(there are continuous sections and linear equipment components).

How does a rolling mill work? First, the metal ingot is heated in special wells (temperature is about 1800 C), after which the electric car delivers it for primary processing (for slabbing or blooming), where bars are obtained from the ingot. Further, metal sheets or finished products of a given shape, such as rails, etc., are obtained from them on other rolling equipment. Modern equipment, as a rule, is foundry and rolling mills that can process billets in stands at a speed of about 300 km per hour.

Manufacture of rolling mills is a complex and expensive process, however, today in Russia there are enterprises that produce such products. In addition to the main and auxiliary equipment, the successful operation of the complex requires high-precision automation, lubrication equipment, as well as the provision of mills with electricity with a total capacity of up to 200-300 megawatts.

Recommended:

Modern production. The structure of modern production. Problems of modern production

Developed industry and a high level of the country's economy are key factors influencing the we alth and well-being of its population. Such a state has great economic opportunities and potential. A significant component of the economy of many countries is the production

Classes of the Nice Classification: codes, list and classifier. What is the International Classification of Goods and Services?

For the registration of each mark of new products in business, the International Classification of Goods and Services is used. At the initial stage, the applicant determines under which category his activity falls. In the future, this will be the basis for the implementation of registration procedures and determining the amount of the fee paid by the entrepreneur

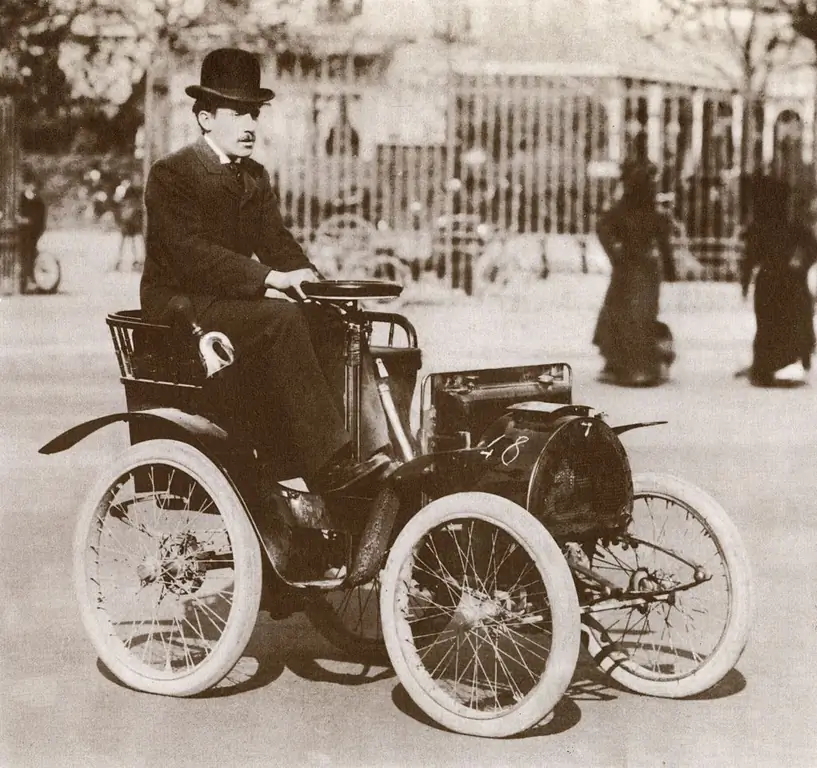

"Renault": manufacturer, history and date of creation, management, country, technical focus, development stages, introduction of modern technologies and car quality

The Renault manufacturer produces high-quality cars that are in demand in many countries of the world. The products were to the taste of Russian motorists. In 2015, the French concern produced the millionth car from the lines of the Russian plant

Traction rolling stock: classification, types, device and characteristics

At present, the railway communication is developed quite strongly. In order to move massive wagons, traction rolling stock is used. To date, such trains include locomotives, as well as multiple unit rolling stock

Vitamin plant in Ufa: history and date of establishment, management, addresses, technical focus, stages of development, introduction of modern technologies and product quality

The life of a modern person takes place in a rather unfavorable ecological environment, accompanied by intellectual and emotional overload. You can't do without taking vitamins and minerals even in the summer. This material will focus on one of the oldest enterprises in Ufa, which is engaged in the production of useful products