2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:32

Concrete is tested for strength using special instruments. As a rule, they consist of sensors, as well as a conductor. Modules for devices are selected with adapters. Models differ in measurement accuracy and allowable temperature. Many devices use controllers. If we consider electronic meters, then they have a screen. In order to understand this issue in detail, it is recommended to familiarize yourself with the existing methods for measuring the strength of concrete.

Methods for testing the strength of concrete

First of all, the laboratory method is distinguished. It consists in adding indicator substances. For this purpose, a sample is taken and then diluted in a reagent. The second method is to press the substance. Strength testing of concrete is carried out by pressure calculation. The last method is called non-destructive testing. Special devices are produced for this.

Mechanical meters

You can check the compressive strength of concrete using mechanical meters. They provide a tube to which a wired sensor is attached. Departs from hima special contactor that closes on the plate. Many modifications work with all brands of concrete. The contacts in the device are highly conductive. A catcher is used to test the compressive strength of concrete. As a rule, the data is shown with an arrow.

Electronic meters

Recently, electronic modifications are in great demand. The models use a special block. It receives data on the parameters of concrete. With the help of the module, all information is calculated. Many models have the option to enter initial data. Microcircuits for such meters are of the contact type.

Calculation of concrete is carried out thanks to the work of the module. There are no catchers in this case. The sensors are used with low conductivity filters. Most devices have a high correlation threshold. The maximum allowable temperature of the meters is 45 degrees. Cases are quite often made of plastic, while sensors are made of aluminum alloy.

Low precision devices

Inferior precision concrete strength meters are typically used on construction sites. These devices can be produced with a mechanical sensor. Most models are equipped with contact transmitters. If we consider the Beton Pro Condtrol meter, then it gives an error in the region of 0.3%. At the same time, its correlation coefficient is quite high.

The conductivity of this type of meters is not very good. Minimum allowable temperatureis about -15 degrees. If we consider the Onyx device, then it is not allowed to use it at high humidity. The auto-calibration option is provided in almost all meters. The minimum strength level for measurement is 3 N. Concrete can be tested in different grades. Catchers for models are used with low sensitivity. Speaking of advantages, it is also worth noting that the devices are cheap.

High accuracy models

When testing the strength of concrete, a high precision instrument can be very useful. Devices of this type are usually used by professional builders. Modifications are also actively used in the laboratory. The models are equipped with special electrode sensors. They process data on the density and moisture content of the sample. It should also be noted that they can work at elevated temperatures. Probes in devices are used channel type. The minimum allowable temperature of the meters is approximately -10 degrees.

Contactors in the device are used with expanders. Control units are used with a microprocessor. If we consider electronic devices, they often have modules installed. The concrete calculator is calculated using the controller. Cards are used to store data. The accuracy of data processing is quite high. In this case, the maximum error factor is 0.2%. Traps are used with and without transmitters.

Devices with electronic unit

Electronic units are usually sold with a probe. Some modifications are equipped with displays for reading data. Processing modules are highly conductive. Some meters operate in high humidity. Models are ideal for laboratories. Their correlation coefficient fluctuates around 55%. Additionally, it is important to note that there are meters with channel electrodes. Microprocessors for them are selected on operational amplifiers. The concrete calculator is calculated by the device thanks to the controller. Most models work with a transmitter. The minimum allowable concrete density is 5 N.

Models with sensor

Concrete strength meters with sensors are valued for their compactness. Many models use channel probes. It should also be noted that there are modifications on wired transistors. Transmitters for them are selected multi-channel type. The conductivity coefficient in devices of this type is at least 5 microns. The minimum allowable temperature of the meters starts from -15 degrees. Most devices operate in high humidity.

If we consider electronic modifications, then they use a module with an auto-calibration function. Contacts are selected in different forms. Also on the market are specialized diode devices with an indication system. Quite often they are used in large construction enterprises. Modules for them are suitable with high conductivity. It should also be noted that traps are installed on the meters, and the devices are powered by lithium batteries.

Sclerometer devices

Concrete strength meters with a sclerometer are highly accurate. Most models are made with contact sensors. Some devices are capable of boasting a high conductivity coefficient. In this case, the sensitivity index starts from 4.5 mV. The minimum allowable temperature of this type of meters is -10 degrees. Sclerometers are installed with tubes, at the end of which there is a catcher. The contactor is mounted on a special holder. The data is usually displayed. For fast data processing, a modulator is installed. Some devices are made with a chip that can store data.

Devices with data backup function

Models of this type are produced with cards that read information from the control unit. Probes in devices are used in different directions. Microprocessors are typically used with impulse conductors. Contactors come in a variety of forms. Most devices are powered by a dipole modulator. If we talk about compact devices, they have a short tube. In this case, the sensor is used one-sided type.

The conductivity coefficient in devices reaches 4.3 microns. In this case, the maximum sensitivity is 9 mV. The minimum allowable temperature of this type of meters is -20 degrees. Transmitters are used with channel conductors. Filters are often set to 4pF. Catchers are installed quite rarely. For charging models applylithium type batteries. Most meters support auto calibration.

Models with pulse sclerometer

Concrete strength meters of this type have good sensitivity. They are capable of automatic calibration. Devices are used for different grades of concrete. The minimum allowable temperature of the meters is -10 degrees. Contacts they use positive conductivity. Most modifications are equipped with only one probe. In this case, the transmitters are used for two outputs. Processing data from models takes a lot of time. Some devices are made with dipole modulators. The main disadvantage of devices is the low correlation coefficient.

Modifications with diode sclerometer

Diode sclerometer devices can quickly measure strength. At the same time, data processing does not take much time. Some devices are manufactured with flat-panel displays that differ in resolution. It should also be noted that there are meters with contact probes.

Diagnosis of concrete is carried out using a modulator. Most models can be used in high humidity. The minimum allowable temperature of this type of meters is -10 degrees. The electrodes in this case are installed in the tube. Some models are equipped with dipole traps. Meter protection systems are of class P40.

Professional models

Professional modifications only work on wired modules. Their contactsinstalled with a conductivity of 5.5 microns. The devices are well protected and are not afraid of high humidity. Additionally, they have a calibration function, and data archiving. Control units are used with a microcircuit. Some devices run on lithium batteries. Battery versions are also available. The measurement accuracy of the devices starts from 98%. Probes are used tubular type. Protection systems, as a rule, are applied in class P55. Most meters are made with displays.

Compact devices

Compact meters are made with dipole traps. In this case, tubes of small diameter are used. Most devices are made without probes. It should also be noted that there are modifications of low conductivity. Their correlation coefficient is only 60%. Microprocessors can work on filters. The minimum allowable temperature for compact meters is -10 degrees. Batteries are often used with low capacity. The electrodes in the devices are made with a sensitivity of 3 mV. The coefficient of dielectric constant is not more than 30%. The automatic calibration feature is not available on all devices.

Glatec models

Devices of this brand are distinguished by high-quality probes. Some models are actively used in construction enterprises. The minimum strength level for measurement is 3 N. Microcircuits in devices are used with high conductivity. Concrete calculationhappens very quickly. Models make contacts with and without transmitters.

Sensors are applied at 3 and 5 mV. The correlation coefficient, as a rule, is in the region of 60%. The minimum allowable temperature for meters of this brand is at least -10 degrees. In addition, the company specializes in the production of high conductivity models. Their sensitivity parameter is induced at the level of 4.5 mV. Many modifications are made with contactors.

Recommended:

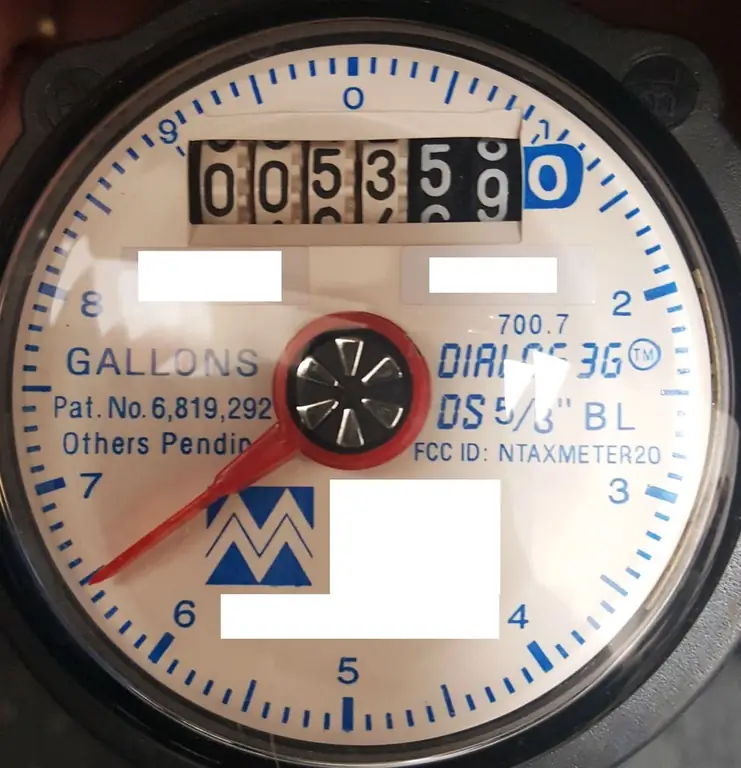

Shelf life of water meters: period of service and operation, verification periods, operating rules and time of use of hot and cold water meters

The shelf life of water meters varies. It depends on its quality, the condition of the pipes, the connection to cold or hot water, the manufacturer. On average, manufacturers claim about 8-10 years of operation of devices. In this case, the owner is obliged to carry out their verification within the time limits established by law. We will tell you more about this and some other points in the article

Basic testing methods for asph alt concrete

The problem of the quality of the road surface in our country is extremely acute. Therefore, it is very important when accepting the work of construction services to qualitatively and correctly test reinforced concrete. And based on the results of these works, a decision should already be made on the commissioning of road transport infrastructure facilities. In this article, we will talk about the features and rules (GOST) of testing asph alt concrete

Ultrasonic testing of welded joints, methods and technology of testing

Ultrasonic testing - advanced technology for the study of welding joints and seams. It will be discussed in this article

Concrete strength curing schedule: features, types, technology and key indicators

Concrete solution for a certain time after pouring will acquire the desired performance properties. This time interval is called the holding period, after which a protective layer can be applied

Determination of concrete strength: methods, equipment, GOST. Control and evaluation of concrete strength

When checking building structures, the determination of the strength of concrete is carried out to determine their state at the current time. Actual performance after the start of operation usually does not match the design parameters