2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

Cast iron pipes are used today in the laying of external and internal sewerage systems. Products can be channelless and channel. Their service life can reach 100 years. Connecting elements and assortment of sewer pipes is determined by GOST 6942-98. After reading the documentation, you will be able to understand what parameters pipes should have.

Dimensions and diameters

When considering the dimensions of cast iron sewer pipes, you should know that today there are three units of sizes. They differ in cross section. The main types are SMU and SME. The former have smooth ends, the latter have one end smooth and the other has a bell. Tubular products are marked according to the nominal section.

Looking at the inscription, in its first part you will see the grade of the material. Furtherthe nominal cross section is indicated. For example, if the marking looks like this: Dn 100, while the inner diameter will be 100 mm, and the outer one will be 110 mm. Considering the dimensions of cast iron sewer pipes, you should pay attention to products with a socket, which are divided into three classes. Each of them has its own wall thickness and is designated by the letters A, B or LA.

From the size table of cast iron sewer pipes, you can find out that the products have an outer diameter ranging from 81 to 429 mm. And one of the main indicators - the conditional passage varies from 65 to 400 mm. As for the wall thickness, it cannot be different, and depending on this, the pipe belongs to class A if the thickness varies from 7.4 to 13.8. When the pipe belongs to class B, the wall thickness varies from 8 to 15 mm, but for a pipe of class LA, the wall thickness ranges from 6.7 to 12.5 mm.

The weight of the pipe depends on the dimensions. For example, if you have a Du50 pipe in front of you, then its mass will be 11 kg. A DN 1000 pipe will weigh 620 kg. Intermediate values of 40 and 25 kg are correct for DN150 and DN100 pipes, respectively. But this mass is assumed. It may differ from the real one. Due to the impressive weight, cast iron products are sold in segments, the length of which varies from 0.75 to 7 m.

When considering the size of cast iron sewer pipes, you should consider that you should not purchase a product with a thick wall if the pressure in the system is low. This will reduce purchase costs as well as installation and transportation costs.

Ohsockets and their sizes

The dimensions of the sockets of cast iron sewer pipes are determined by the type of these parts of the products, which can be I, II, III and IV. The dimensions and design of the bell type 1 differ from the rest. If the nominal bore is 50 mm, then the socket diameter is 55 mm. When the orifice increases to 150 mm, the inside diameter of the socket becomes 155 mm. In this case, the outer diameters of the sockets will be equal to 90 and 202 mm, respectively.

In this section, you can also consider the dimensions of a 100 mm cast-iron sewer pipe. In this case, the inner diameter of the socket will be 123 mm. With an increase in the nominal bore to 150 mm, the inner diameter of the socket increases to 176 mm.

Main types and their features

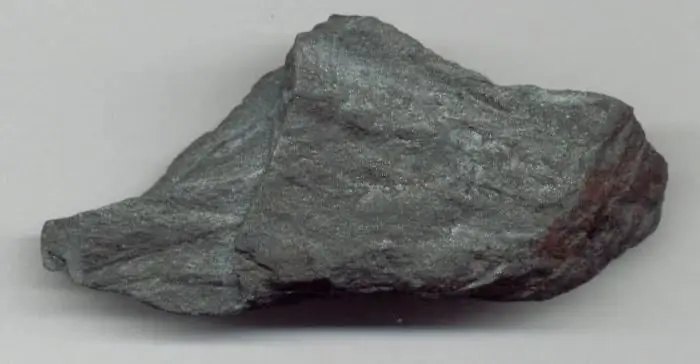

Described products can be socketed, socketless, pressure and non-pressure. In many industries, pipes, which are abbreviated VSHCHG, have found their wide application. As part of such a pipe, nodular graphite makes the product more elastic and viscous. Such pipes replace the analog of gray cast iron. According to their properties, they can be equated to cast and forged steel. In terms of mechanical characteristics, these pipes can compete with steel products due to the high coefficient of corrosion resistance. Their service life is 8 times higher than analogues. Pressure products can be used to work with aggressive substances. They do well in winter. They are not afraidfrosts.

The pipes are highly durable, which means that they can be laid under highways, while the installation depth can be quite impressive. Such a cast-iron sewer pipe, the dimensions and GOST of which were mentioned above, can be bell-shaped or have rubber seals.

Free-flow pipes and their properties

The material contains lamellar graphite, so the products do not have the proper strength. Gray cast iron is used for their manufacture. Such pipes are installed in those systems where high loads are excluded. They can be mounted together with plastic pipes.

You can use rubber cuffs to get a secure connection. The main advantages of these cast iron sewer pipes, the dimensions of which were mentioned above, include the possibility of being used a second time after dismantling.

Cubless pipes and their properties

The material contains graphite. For greater strength, the inner walls of the pipe are coated with epoxy resin. This allows you to get rid of the formation of layers and siltation. Epoxy resin performs well in an aggressive environment and saves the material from corrosion and destruction. The table of diameters of cast iron sewer pipes will allow you to understand what parameters the described products have. As for SML, which is also called socketless, it does not need to create additional noise protection.

Products meet fire safety requirements, are able to withstand heat and have high strength. Clamps are used to connect the elements of the system. This is due to the lack of sockets at the ends. Such pipelines first became known in the early 60s. In those days, engineers worked on the creation of new technologies and materials. Today, socketless designs remain reliable and are considered a quality way of manufacturing systems, the butt joints of which are highly tight without the use of sealing materials. This is due to the lack of bells.

The internal coating of the products is very smooth, so they differ from analogues in increased throughput. The absence of corrosion explains the high wear resistance. These products can function at any temperature, they are resistant to impressive drops. The pipe is easy to process, in addition, it contains graphite. Thanks to him, the strength of the material becomes quite impressive. The wall thickness does not change along the entire length.

Properties of socket products

These pipes remain popular today, despite the flooding of the market with new materials. They are used in various industries, and their main advantage is an increased service life, which is especially true when compared with other analogues. This is due to the fact that steel begins to rust over time. The disadvantage is the brittleness of cast iron. Labor intensityinstallation is more difficult compared to other pipes. In order to exclude the effects of corrosion, the products are coated inside and out with bitumen.

Cost of pipes

Sizes and prices of cast iron sewer pipes from the catalog can be found. For example, a pipe, the length of which is 2 m, and the conditional passage is 50 mm, costs 1091 rubles. A pipe with a nominal bore of 100 mm and a length of 2 m will cost 1,765 rubles. If the conditional passage increases to 150 mm, and the length remains the same, then the price of such a product will be equal to 3222 rubles. You can buy a meter-long cast-iron pipe with a conditional bore of 50 mm for 978 rubles

Features of installation and docking

During installation, special attention is paid to the docking of products. In order to achieve the perfect result, you should prepare a putty without wood waste and impurities. Before filling the socket with a mixture of asbestos cement, it is necessary to fill it with a tarred hemp strand. Then it is folded with a tourniquet and caulked into the slot of the bell. Care must be taken.

The thickness of the bundle should be greater than the width of the gap, the length should be such that the strand enters the socket 30 mm from the edge. To obtain a mixture of cement and asbestos, mix Portland cement grade 400 and asbestos fiber. These ingredients are mixed in a ratio of 70 to 30.

Before use, the mixture is moistened by adding water in a volume of 12% by weight. Docking of fittings with cast-iron pipes is carried out by closing the gaps that occur between the inner surface of the socket and the fitting or the end of the pipe. When installing the pipe, the direction of the socketmust be secured in the opposite direction of the fluid movement.

In conclusion

At the peak of popularity today, plastic pipes. The area of their use is wide, but when installing sewer systems, steel and cast iron products occupy a leading position. They are wear-resistant, have good soundproofing characteristics, are durable and have an optimal stretch rate, which is important for long-term operation.

Recommended:

Types of cast iron, classification, composition, properties, marking and application

The types of cast iron that exist today allow a person to create many products. Therefore, we will talk about this material in more detail in this article

Types and diameters of metal pipes. Metal pipes of large diameters

Steel pipe is a cylindrical tube and is the most used product in the steel industry. The main use of steel pipes is to transport oil, gas and water over long distances. In household appliances, such as refrigerators, ordinary steel pipes are used, as well as in heating and water supply systems

White cast iron: properties, application, structure and features

Initially, the technology of casting iron was first mastered in China in the 10th century, after which it became widespread in other countries of the world. A prominent representative of such an alloy is white cast iron, which is used in mechanical engineering for the manufacture of parts, in industry and in everyday life

Railway track is Definition, concept, characteristics and dimensions. Train dimensions and features of track facilities operation

Traveling by train through cities and towns, you can learn a lot of interesting and amusing things about the world of the railway. More than once, traveling people have asked themselves questions about where this or that railway track leads? And what does the engineer who manages the train feel when the train is just starting off or arriving at the station? How and from where do metal cars move and what are the ways of the rolling stock?

Diameters of polyethylene pipes: external, internal, purpose of pipes

What diameters polyethylene pipes have, you now know. However, for the installation of these products, it is necessary to familiarize yourself with the features of docking. Connections may or may not be detachable. The former provide for the possibility of disassembling the system during operation. To create such a connection, steel flanges are used. During operation, disassembly cannot be carried out if the connection is one-piece