2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:38

Initially, the technology of casting iron was first mastered in China in the 10th century, after which it became widespread in other countries of the world. The basis of cast iron is an alloy of iron with carbon and other components. A distinctive feature is that in its composition cast iron contains more than 2% carbon in the form of cementite, which is not found in other metals. A prominent representative of this alloy is white cast iron, which is used in mechanical engineering for the manufacture of parts, in industry and in everyday life.

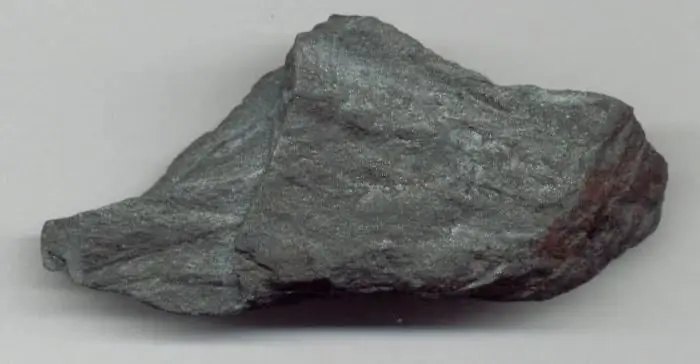

Appearance

The alloy has a white color at the break and a characteristic metallic luster. The structure of white cast iron is fine-grained.

Properties

Compared with other metals, iron-carbon alloy has the following characteristics and properties:

- high brittleness;

- increased hardness;

- high resistivity;

- low casting properties;

- low machinability;

- good heat resistance;

- large shrinkage (up to 2%) and poor mold filling;

- low impact resistance;

- high wear resistance.

Metal mass has great corrosion resistance in hydrochloric or nitric acid. If there are free carbides in the structure, then corrosion will occur when cast iron is placed in sulfuric acid.

White cast irons, which contain a lower percentage of carbon, are considered more resistant alloys to high temperatures. Due to the increased mechanical strength and toughness that appear when exposed to high temperatures, the formation of cracks in castings is minimized.

Composition

Iron-carbon alloy is considered to be a cheaper material than steel. White cast iron contains iron and carbon, which are in a chemically bound state. Excess carbon, which is not present in the solid solution of iron, is contained in the combined state in the form of iron carbides (cementite), and in alloyed cast iron in the form of special carbides.

Views

Depending on the amount of carbon content in white cast iron, it is divided into the following types:

- Hyotectic holds from 2.14% to 4.3% carbon and after complete cooling acquires the structure of perlite, secondary cementite and ledeburite.

- Eutectic contains 4.3% carbon and has a structure in the form of a light background of cementite, which is dotted with dark grains of perlite.

- Hyotectic has from 4.3% to 6.67% carbon in its composition.

Application

Based on the above properties,it can be concluded that it makes no sense to practice thermal and mechanical processing of white cast iron. The alloy found its main application only in the form of a casting. Consequently, white cast iron obtains the best properties only if all casting conditions are met. This processing method is actively used if it is necessary to produce massive products that must have high surface hardness.

In addition, white cast iron is annealed, resulting in malleable cast irons, which are used to make thin-walled castings, for example:

- automotive parts;

- agricultural products;

- parts for tractors, combines, etc.

The alloy is also used to make plates with ribbed or smooth surfaces, and is also actively used in the production of steel and gray iron.

The use of white cast iron in agriculture as a structural metal is rather limited. Most often, iron-carbon alloy is used for the manufacture of parts for hydraulic machines, sand throwers and other mechanisms that can operate in conditions of increased abrasive wear.

chilled cast irons

This alloy is considered a type of white cast iron. It is possible to achieve a chill of 12-30 mm by rapidly cooling the surface of the iron-carbon alloy. Material structure: the surface part is made of white, gray cast iron in the core. Wheels, balls for mills, rolling rolls are made from such material, which are mounted inmachines for processing sheet metal.

Alloying elements of the alloy

Specially introduced alloying substances added to the composition of white cast iron can give greater wear resistance and strength, corrosion resistance and heat resistance. Depending on the amount of added substances, these types of cast iron are distinguished:

- low-alloy alloy (up to 2.5% auxiliary substances);

- medium alloyed (from 2.5% to 10%);

- highly alloyed (more than 10%).

Alloying elements can be added to the alloy:

- chrome;

- sulfur;

- nickel;

- copper;

- molybdenum;

- titanium;

- vanadium,

- silicon;

- aluminum;

- manganese.

Alloyed white cast iron has improved properties and is often used for casting turbines, blades, mills, parts for cement and conventional kilns, pumping machine blades, etc. The iron-carbon alloy is processed in two furnaces, which makes it possible to bring the material to a certain chemical composition:

- in the cupola;

- in electric furnaces.

Castings made of white cast iron are annealed in furnaces to stabilize the required dimensions and relieve internal stress. The annealing temperature can rise up to 850 degrees. The process of heating and cooling must be done slowly.

Marking or designation of white cast iron with impuritiesbegins with the letter H. Which alloying elements fit in the composition of the alloy can be determined by the subsequent letters of the marking. The name may contain numbers that indicate the percentage of additional substances that fit in white cast iron. If the marking contains the designation Ш, then this means that the structure of the alloy contains spherical graphite.

Types of annealing

For the formation of white cast iron in the industry, rapid cooling of the alloy is used. Today, the following main types of carbon alloy annealing are actively used:

- softening annealing is mainly used to increase ferrite in cast iron composition;

- annealing to relieve internal stresses and minimize phase transformations;

- graphitizing annealing, resulting in malleable cast iron;

- normalization at a temperature of 850-960 degrees, resulting in graphite and perlite, as well as increased wear resistance and strength.

Additional information

To date, it has been proven that there is no direct relationship between wear resistance and hardness of a carbon alloy. Only due to the structure, namely the arrangement of carbides and phosphides in the form of a regular grid or in the form of uniform inclusions, increased wear resistance is achieved.

The strength of white cast iron is most intensively affected by the amount of carbon, and the hardness depends on the carbides. The greatest strength and hardness are those cast irons thathave a martensitic structure.

Recommended:

How to cook cast iron by electric welding: work technology and necessary materials

The main composition and types of cast iron. Difficulties and features of welding cast iron products. Cast iron welding methods. Preparatory operations before welding. How to cook cast iron by electric welding in a cold and hot way, as well as gas equipment. Features of the electrodes used for welding cast iron. Safety measures during welding

Diameters and dimensions of cast iron sewer pipes. Types and features

Cast iron pipes are used today in the laying of external and internal sewerage systems. Products can be channelless and channel. Their service life can reach 100 years. Connecting elements and assortment of sewer pipes is determined by GOST 6942-98. After reading the documentation, you will be able to understand what parameters the pipes should have

Alloy cast iron: grades, properties and applications

Alloyed iron is a material that is produced by smelting in blast furnaces. It can contain different amounts of carbon. Depending on the quantitative content of this substance, two types of cast iron are distinguished. The first is called conversion, or white, and the second is gray, or foundry

Types of cast iron, classification, composition, properties, marking and application

The types of cast iron that exist today allow a person to create many products. Therefore, we will talk about this material in more detail in this article

Organizational structure of Russian Railways. Scheme of the management structure of Russian Railways. Structure of Russian Railways and its divisions

The structure of Russian Railways, in addition to the management apparatus, includes various dependent divisions, representative offices in other countries, as well as branches and subsidiaries. The head office of the company is located at: Moscow, st. New Basmannaya d 2