2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:34

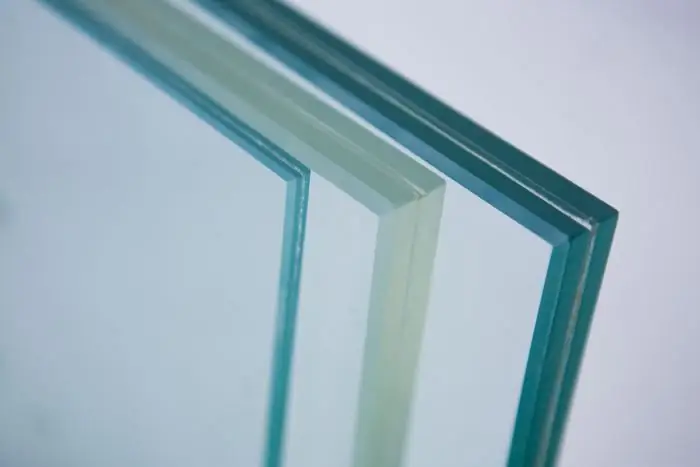

Glass has found the widest application in the interior design of rooms and facades of buildings. Without it, it is impossible to imagine any window construction, and the manufacture of transparent furniture has long been a promising type of business. However, along with the positive qualities, there are disadvantages: when broken, fragments with sharp edges are formed, which can cause an accident. To prevent such situations, tempered glass (stalinite) is used, which, when damaged, breaks into many small particles.

Production

The manufacturing process is almost identical to the standard technology. By heat treatment of a mixture of sand and quartz to a viscous state, a transparent mass is formed, which is shaped into sheets by rolling.

After that, to change the physical properties of products, a procedure of repeated hardening is necessary. The professional production of tempered glass is done by heating the surface to 700 ° C, and then blown with cold air flows in order to cool faster. As a resultSuch an impact on the glass surface causes a compressive stress, which is the reason for the increase in resistance to mechanical stress. However, when the load is increased, the entire surface of the product is rapidly destroyed - it crumbles into many small fragments with non-sharp edges.

Before installing the glass, you should carefully read its physical parameters.

Properties

When the manufacturing technology is observed, tempered glass acquires unique performance characteristics. They are expressed in increased safety of use and the almost complete elimination of accidents - cuts and injuries.

In addition, it is worth noting the increase in strength compared to ordinary glass. The maximum load on the surface can be about 300 kg per 1 m². Significant temperature differences also do not affect the change in the properties of the product. But tempered glass has some disadvantages:

- After manufacturing, surface treatment is almost impossible. Cutting tempered glass can only be done with the help of special equipment - a diamond blade with constant water cooling.

- High cost compared to standard products.

- Increase in share.

The unique properties of tempered glass make it possible to use it in many areas of life.

Processing and cutting

Changing the structure of tempered glass directly affects the processing procedures. It refers to changeproduct configuration, drilling holes, etc. To give the glass the desired shape, it is best to complete all work before the tempering procedure.

But this is not always possible - in some cases it is necessary to cut the finished product. If you have a special processing machine, the procedure for changing the configuration will not be difficult. It is enough to set a specific cutting program. Processing glass by hand is very problematic. But in some cases it succeeds. It should be noted right away that with the help of a conventional glass cutter, products with a maximum thickness of 5 mm are processed. To partially relieve the tension, the surface of the tempered glass is wiped with a White Spirit solvent. Then, in one motion, it is necessary to make an incision along which a fracture will occur. Efforts to separate are small, and in no case should you tap on the glass.

Glazing

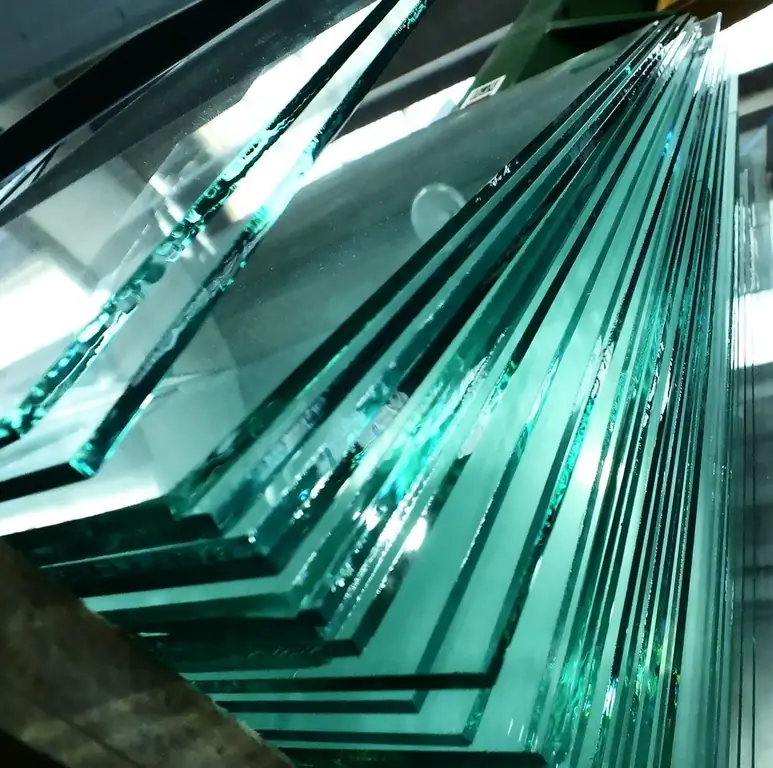

Due to its unique properties, tempered glass can be used in many areas: from installation in window structures to the manufacture of luxury furniture. Its durability and safety have become fundamental factors in its popularity.

But the main purpose of tempered glass is still the manufacture of transparent structures for building facades. To create a panoramic view, large sizes of structures are used. Since the weakest point of tempered glass is its end, precautions should be taken before installing it into the window frame. Furtherthe design successfully withstands high wind loads and mechanical stress.

Differences

It is almost impossible to distinguish a hardened product from a regular one by appearance. The result is revealed only when broken, or when the question arises, how to cut tempered glass? This is necessary to select the optimal technology for changing the configuration. If you try to cut ordinary glass on a machine with a diamond blade, then as a result it may be damaged, broken.

There are several ways to tell the difference:

- Special device for determining the brand of glass. Used in factories.

- Different sound when lightly tapped. The hardened surface resonates waves in a low pitch. The sound is muffled.

- When viewed through polarized lenses, small grid lines can be seen on the tempered glass surface.

But the most optimal way is to use a point device. Its cost is relatively high, but it will quickly cover possible production damage resulting from processing the wrong product.

Recommended:

How to make glass? Glass production technology. glass products

Glass is familiar to everyone. But the process of making it is extremely exciting. Each stage is important and affects the quality of the final product. The basis is sand, soda, lime. The process is almost entirely automated. Surprisingly, glass can even be made at home

Tempered glass for industry and phones

Tempered glass is an ordinary transparent sheet type material. It is created by heating to a temperature of 650-680 ° C. After reaching this mark, there is a sharp and uniform air cooling

Glass sandblasting: glass processing description, equipment, application, photo

Among the numerous variations of interior decoration, sandblasting of a glass or mirror surface occupies a special place. This technology involves exposing the canvas to sand or other abrasive with a jet of compressed air released under high pressure. As a result, the surface changes and becomes matte, rough, velvety or painted with patterns. In the article we will consider what is sandblasting glass

Can glass be tempered, and how is this product characterized?

Recently, there has been a steady popularity of the use of glass products in interior design, including external glazing. Current production technologies make it possible to obtain clean glass of absolutely any shape and size. However, no matter how beautiful it may be, this does not make it the most protected from mechanical damage. In fact, when glass falls even a few centimeters, it is first covered with small cracks, and then instantly crumbles

Meat: processing. Equipment for meat and poultry processing. Production, storage and processing of meat

Information of state statistics show that the volume of meat, milk and poultry consumed by the population has significantly decreased in recent years. This is caused not only by the pricing policy of manufacturers, but also by the banal shortage of these products, the required volumes of which simply do not have time to produce. But meat, the processing of which is an extremely profitable business, is very important for human he alth