2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:29

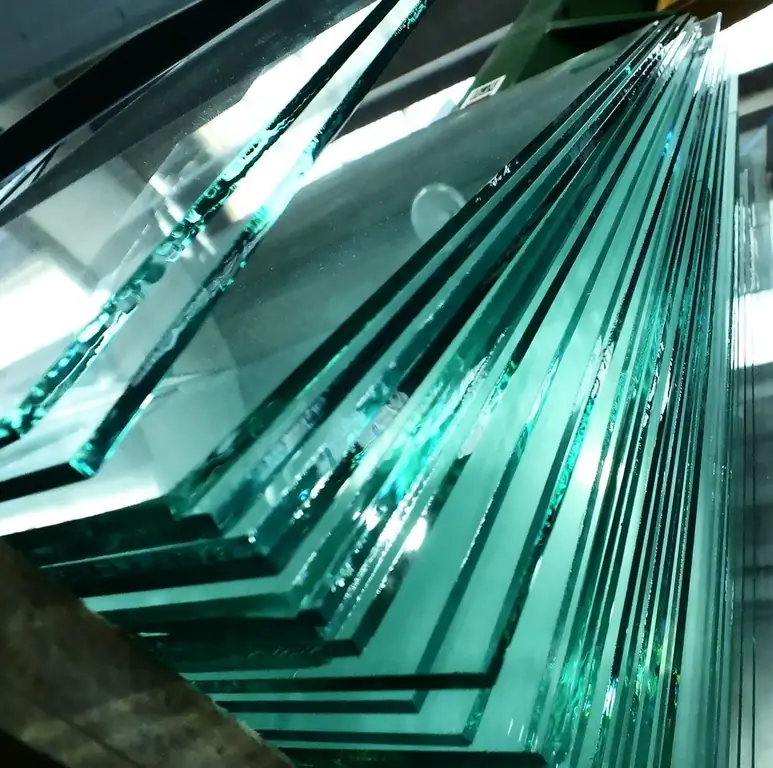

Recently, there has been a steady popularity of the use of glass products in interior design, including external glazing. Current production technologies make it possible to obtain clean glass of absolutely any shape and size. However, no matter how beautiful it may be, this does not make it the most protected from mechanical damage. In fact, when glass falls even a few centimeters, it is first covered with small cracks, and then instantly crumbles. But the engineers took this moment into account, and therefore now a special tempered type of glass is used in almost all facade design of premises. Why is it so popular and what are its characteristics?

What is it?

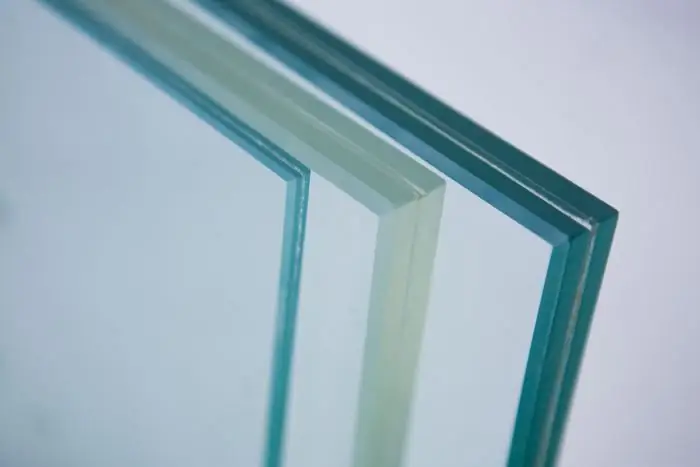

According to GOST, tempered glass is a material that, during production, is heated to a temperature of 650-700 degrees Celsius and then sharplycooled down to the minimum. Thus, due to the difference in heating, the heat treatment process, that is, hardening, takes place. As a rule, the output of such material is characterized by high reliability and impact resistance. Experts have calculated that this type of tempered glass is 4 times stronger than the one called ordinary stalinite. In addition, you should pay attention to the safety of its use. Fragments of this material are characterized by lower cutting properties. At the same time, when falling, ordinary stalinite breaks into hundreds of small grains of glass, which dig into the skin so quickly that pain from their presence under the skin occurs only for the following days. Tempered glass shards have blunter edges, which prevents the risk of serious injury to a person.

Dimensions

The production of tempered glass is carried out on special technical equipment, while the dimensions of the resulting material can be as follows:

- length and width - from 200 to 3600 millimeters;

- thickness - from 4 to 19 millimeters.

Before tempering the glass, craftsmen choose the required dimensions and, if possible, cut it to the desired shape. Why can't such glass be processed after tempering? The fact is that the surface of this material, along with high strength, does not make it possible to make any changes in its shape. And this means that there is simply no point in cutting and drilling the surface of a hardened part. It should be noted that tempered glassonly possible with the help of sophisticated technical equipment. Simply heating a piece of glass on the stove and quickly lowering it into cold water will not work. Such material will simply crumble into small fragments or, at best, simply crack. Therefore, if you want to temper glass, please contact specialized companies that provide such services with this request.

Specifications

The temperature range of operation of such material is from -150 to +300 degrees Celsius. And this despite the fact that stalinite can withstand a temperature drop of only 40 degrees. In this regard, an increasing number of construction companies are asking the question "how and where to temper glass for external glazing?"

Recommended:

How to make glass? Glass production technology. glass products

Glass is familiar to everyone. But the process of making it is extremely exciting. Each stage is important and affects the quality of the final product. The basis is sand, soda, lime. The process is almost entirely automated. Surprisingly, glass can even be made at home

Tempered glass for industry and phones

Tempered glass is an ordinary transparent sheet type material. It is created by heating to a temperature of 650-680 ° C. After reaching this mark, there is a sharp and uniform air cooling

Tourist product: creation, development, features, consumers. The tourism product is

Any theme park, hotel or other tourism enterprise is invariably faced with the choice of what to produce and how much. The inevitability of this problem is obvious. After all, tourism organizations have a small amount of production resources. The final decision will depend on the purpose of the firm, as well as on the restrictions and obstacles that will be in its way

What is tempered glass: features of production, processing and applications

How is tempered glass different from regular glass? A description of the production process and the specifics of processing will help to find the answer to this question. Methods for determining tempered glass and possible options for cutting it without the use of special equipment

Product rotation - what is it? How does product rotation work in the store?

In trade, there are many techniques and mechanisms that are used to increase sales efficiency and maximize profits. One of these methods is called “product rotation”. What it is? Let's talk about this phenomenon, its types and methods of application