2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

No one is surprised by waterproofs these days: apparel manufacturers are using technological innovations to give their outfits qualities that they could not even dream of before. But how did it all start? Where did waterproof fabrics come from and how did they reach their current level of popularity?

A bit of history: Mr. McIntosh's experience

Waterproof clothing owes its appearance and subsequent popularity to the British scientist Charles Mackintosh. Like many famous scientists, he managed to make a discovery quite by accident. He did not at all wonder how to make the fabric waterproof, but just accidentally dipped the sleeve of his jacket into a container of rubber during the experiment.

After a while, McIntosh noted that such an annoyingly smeared jacket did not lend itself to moisture and acquired water-repellent properties. The only problem was that rubber is very sticky, and waterproof fabric became just as sticky. The chemist thought about it and found a way out: he used two layers of matter, and rubber dissolved in water acted as a waterproof layer.kerosene.

The result satisfied Mr. Mackintosh, and a chemist from Scotland received a patent for his invention.

Waterproof fabric gains popularity

The resulting fabric promised to be a breakthrough, and its creator puts the matter on stream: the first enterprise is opened in the city of Glasgow, where clothes are made from waterproof fabric. But the expected success did not follow: the strong smell of kerosene, which became a side effect of the technological process, was to blame.

Only sailors were not afraid of the suffocating aroma, and they became the main buyers of the newly-minted enterprise. Waterproof fabrics from which the sailors' clothes were sewn saved them from storms and splashes, but they could not withstand the bright rays of the sun and began to melt.

The business, which initially promised big profits, was steadily sinking.

Macintosh and vulcanization

Rubberized fabrics would have remained in history if not for another discovery. In the forties, the process of vulcanizing rubber was discovered: thanks to an innovation, it was possible to obtain a fabric that was resistant to temperatures and did not exude unpleasant odors.

But the author of the discovery, Charles Goodyear, did not want to share the features of the technological process and kept it in the strictest confidence.

Mackintosh and his partner, Thomas Hancock, spent two years persistently experimenting, and they were crowned with success: the process of vulcanizing rubber became available to them.

After this, the state of affairs in the production of Macintosh and Hancock changes dramatically, and rubberized fabric is in great demand and popularity.

Today, many may not know what the waterproof fabric is called and in what year it appeared, but almost everyone knows that the mac is a waterproof elongated raincoat.

How are things today

The business of British chemists is alive and well: waterproof fabrics are in great demand and popularity.

Most often they are used in the manufacture of specialized clothing: for hunters, fishermen, tourists and athletes.

Large manufacturers of clothing for sports and outdoor activities have entire scientific departments that annually present new products and technological developments. Thermal insulation, moisture wicking, extreme temperature resistance, extreme wear resistance - all these qualities are possessed by waterproof fabric. The name of each new copy of the fabric gets its own, depending on the special properties that it has.

Types and features of waterproof fabrics

Modern manufacturers can offer a large selection of waterproof fabrics with different properties and names. But they share common characteristics.

- High density. This leads to the fact that such a fabric lacks elasticity. It is not subject to stretching and shrinkage. Also, the density provides a smooth texture and lack of friability.

- Diagonal, or twill,weaving. If you carefully examine the various waterproof fabrics, you can clearly see the pattern in the form of a diagonal scar on them. This is what twill weave is: the special weave of the threads in the fabric increases the surface tension in the water droplets, so that it cannot penetrate into the fabric. Such ribs provide water-repellent properties of the fabric without special impregnation and processing.

- Practical. In the manufacture of such material, a combination of natural and synthetic threads is used. They perfectly absorb all types of paint, do not sit down and are worn for a long time. This makes waterproof fabrics more practical.

Among the most popular modern types of water-repellent fabrics are the following:

- Taslan. It features a combination of thin and thick threads, which are intertwined in a special way.

- Jordan. This waterproof fabric is quite soft to the touch and has a distinctive sheen.

- Oxford. The most rigid of widely used waterproof fabrics. This material is distinguished by a pronounced diagonal texture.

- Duspo. Its main difference is a matte surface with no signs of gloss. The material has some silkiness.

What is sewn from it

Depending on the composition and type of fabric, it finds its application. Waterproof fabrics with a synthetic base are widely used for sewing overalls for fishermen and tourists, protective aprons and capes for hairdressers, as well asfor the manufacture of various kinds of promotional products (stretch marks, banners).

In addition, thick waterproof fabric can often be seen as furniture upholstery, material for umbrellas and bags, the basis for accessories for the bath and pool.

If the waterproof material has a natural base, it can be used for the manufacture of home textiles: tablecloths, covers for furniture and clothes, curtains, hammocks.

When choosing sportswear, in almost every specialized equipment store you can find a large selection of waterproof fabrics for every taste.

Caring for waterproof fabric

Small dirt is best removed with a sponge and soapy water.

Waterproof fabrics can be washed in a washing machine, taking into account all the manufacturer's recommendations. Usually this is a wash at a low temperature - 30-40 degrees, as well as a gentle cycle.

You can iron such clothes: the higher the percentage of natural threads in a waterproof fabric, the higher the temperature of the iron can be used.

It is not recommended to wash clothes made of moisture-repellent fabric too often, it can quickly lose its basic properties. The use of bleach is also absolutely contraindicated - it will be detrimental to any type of waterproof fabric.

The creators of waterproof fabrics could only dream of such a success: today such material can be found in every home. Proper care and careful handling will ensure a longoperation of products, and they will be able to save their owner from rain and wind for more than one year.

Recommended:

Classes of the Nice Classification: codes, list and classifier. What is the International Classification of Goods and Services?

For the registration of each mark of new products in business, the International Classification of Goods and Services is used. At the initial stage, the applicant determines under which category his activity falls. In the future, this will be the basis for the implementation of registration procedures and determining the amount of the fee paid by the entrepreneur

Tax and tax payments - what is it? Classification, types, concept and types

Currently, the tax system is a set of taxes and fees established by the current legislation of the Russian Federation, which are levied in the budgets of different levels. This system is based on the principles provided by law. Let us consider in more detail the issues of essence, classification, functions and calculation of tax payments

Main types and types of business plans, their classification, structure and application in practice

Each business plan is unique, because it is developed for certain specific conditions. But you need to familiarize yourself with the features of various types of business plans in order to understand their key features. Experts recommend doing this before compiling your own similar document

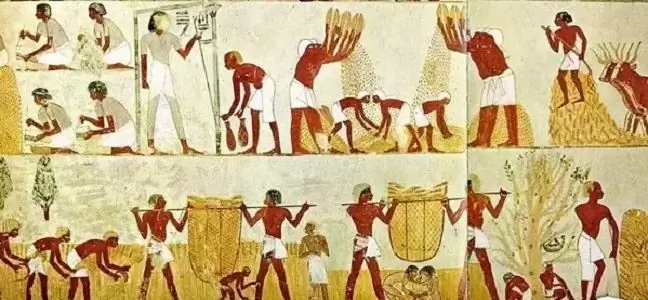

What is fabric made of? Classification of fabrics by type of raw materials, properties and purpose

Using fabric in everyday life, one does not even have thoughts about how significant this invention was for mankind. But without fabrics, life would be uncomfortable and unthinkable! A person is surrounded by tissues in all his life activities. When did the first fabric appear, and what is it currently made of? Let's talk about it in the article

Grape variety Carmenere: variety description, photos, reviews

Carmenere is a grape variety very widespread in Chile. From the bunches of this variety, expensive quality wine is made here. If desired, Carmenere can be grown in Russia, but only in the southern regions