2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Metalworking machine is the common name for a huge number of units that are used in almost any factory. No production that works with non-ferrous, ferrous or ordinary metal can do without the main types of machines.

Main types of devices

It's worth starting with turning devices. They are used most widely, and their main purpose is to change not only the shape, but also the size of the workpiece. The principle of operation of such units is that they cut or grind workpieces using rotating parts of the device for this. In other words, metal processing on a lathe is most often carried out by such types of work as drilling, threading, reaming holes.

The second very popular type of equipment is the milling machine. These machines are of the metal-cutting type, and their main working element is a milling cutter, which exerts strong pressure onworkpiece, constantly rotating. A feature of the machine is that the workpiece can be fed not only rectilinearly, but also curvilinearly. It all depends on the type of work and on the design of the device.

Other types of machines

Today, there are many types of metal processing on machine tools. In many ways, this was made possible thanks to a wide range of equipment.

There is a type of machine that is called boring. This equipment is designed for processing large workpieces. They can perform functions such as drilling or boring, for example. This apparatus has a different principle of operation from the two previous types, since it has a special spindle. This element is capable of axial feed and can be both vertical and horizontal. Various types of cutting tools are attached to the spindle.

There are two more main types of machines - these are drilling and grinding. What they are intended for is well understood from their name. For grinding machines, the main working element is a grinding wheel consisting of abrasive material.

CNC machines are currently a separate category - this is numerical software. To date, machines with such an addition are considered the best. Currently, all of the listed units are produced with built-in CNC. This software helps the operator to control the machine. So don'tno effort should be made to start the device, etc., and the entire process of setting up work is carried out through a computer. Most often, such installations make up the main part of the automatic line in any production where large-scale production of metal parts is required.

Operation of the milling device

Metal processing by a milling machine is a technological operation, which is one of the most common today. On such units there is a milling cutter that performs the main movement, as well as the supply of raw materials. Feed refers to the movement of the workpiece and cutter relative to each other.

Additional machine operating modes

It is worth noting that the processing of metals by a metal-cutting machine of this type is not limited to the main movement of the cutter. There are several auxiliary actions that are used quite often during work. These movements are usually understood as additional movements:

- approach or retraction of the cutter from the workpiece;

- fixation, release, and control of the cutting tool and the workpiece itself;

- there are movements of the devices of the apparatus, which are designed to automatically control the geometric shape of the product.

It is worth noting that there are machines that make it possible to perform auxiliary movements only manually, and there are those that are able to perform them automatically. In addition, all machines are divided into several groups, depending on how many such movements they canperform.

How the machine works

In addition to various devices for metal processing on the machine, there is such a thing as the kinematics of the unit. It should be noted that it may differ depending on the manufacturer of this equipment, but if we talk about domestic devices, then they all have approximately the same circuit.

Work begins with the fact that the motor with a power of 5.5 kW is turned on, which feeds the main movement circuit. This movement is transmitted to the shaft by means of a semi-rigid type coupling. It is important to note here that only two types of rotation can be transmitted - the transmission ratio is 21:41 or 35:27. Further, the rotation is transmitted to the gears, of which the milling machine has as many as 8 pieces.

CNC machines

The use of numerical software on metalworking machines allows you to produce parts that will most closely match the specified parameters. In addition, if CNC machines are used, the number of defective parts can be significantly reduced and the overall quality of finished parts can be improved.

If we talk about the design of such machines, they are almost no different from ordinary ones. The essential difference is that software is added that minimizes the need for human intervention in the workflow.

Types of CNC machines

A metalworking machine can fall into one of four categories, depending on itsweight. Light machines are those that weigh less than 1 ton, the mass of medium machines is from 1 to 10 tons, heavy units weigh from 10 to 100 tons. There is a separate category for devices whose weight exceeds 100 tons, such devices are called unique.

Next, you should pay attention to the fact that the metal processing machine, which has software, can be classified into one of five categories in terms of processing accuracy. In this case, there is a letter marking for the machines.

- N stands for normal precision.

- The letter P means increased, and B - high processing accuracy.

- There are machines of class A in terms of accuracy. This means they are extremely accurate.

- The last category is C class machines. They are considered extremely accurate and are considered master class units.

Versatile equipment

It is worth adding that metalworking machines, which have an integrated CNC system, can be used both for single-piece production, and for serial or large-scale production. On this basis, another classification of equipment was introduced, which distinguishes all machines from each other in terms of their degree of versatility.

- Universal type of machines - these are machines that can produce small batches or single models of elements. Most often they are used in small factories and enterprises.

- Specialized machines are most common in specialized enterprises, as theyare able to produce one part of given parameters, but do it in large quantities.

- Special machines are capable of producing one part, but they are used in mass production.

The main components of the machine

CNC metalworking is of high quality and speed, but in terms of design, they are no different from ordinary ones.

Among the main nodes, it is necessary to highlight the base, which, together with the bed, provides the necessary resistance to vibration. The base of the usual has a rectangular shape.

As for the bed, for lathes, for example, this element is the main one. It consists of two walls, which are interconnected by transverse elements. This is necessary in order to create the necessary strength and rigidity of the structure. In addition, the bed connects other main elements of the machine.

If we conclude from all that has been said, then we can confidently say that today there is a sufficient number of various machines to provide any production with the necessary equipment.

Recommended:

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

Titanium processing: initial properties of the material, difficulties and types of processing, principle of operation, techniques and recommendations of specialists

Today, people are processing a wide variety of materials. Titanium processing stands out among the most problematic types of work. The metal has excellent qualities, but because of them, most of the problems arise

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities

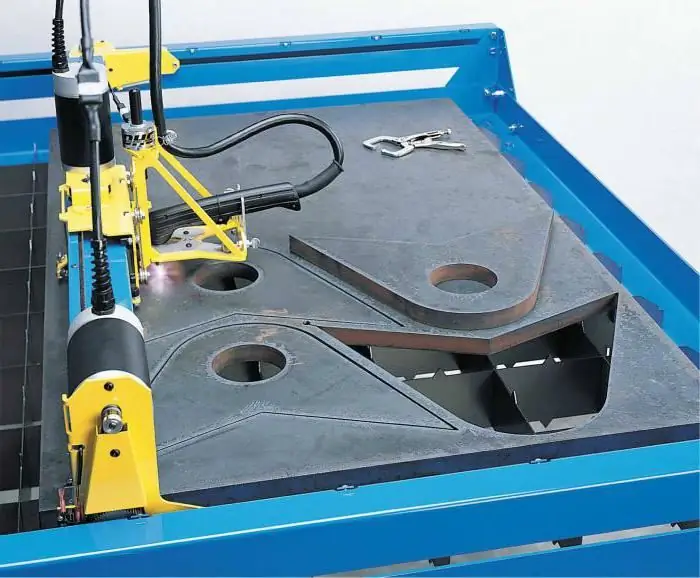

Metal cutting machine. Plasma metal cutting machine

The article is devoted to the apparatus for cutting metal. The technology of plasma cutting, as well as the device and features of the equipment are considered