2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:43

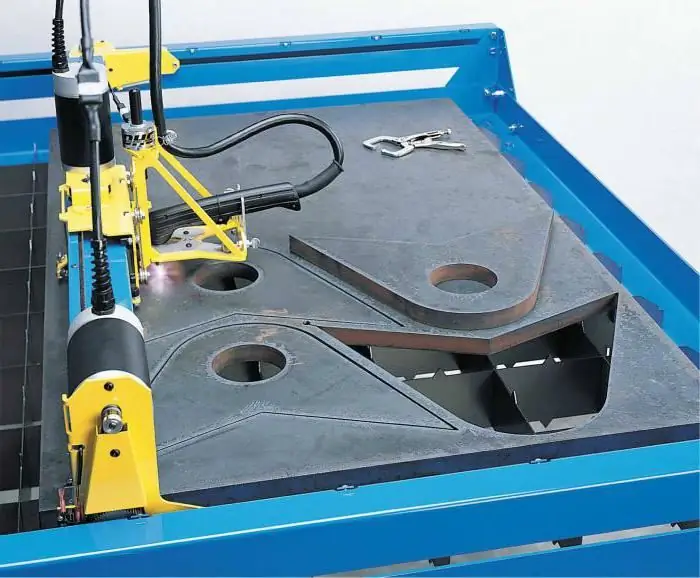

Metal material processing operations require special equipment. In the case of thin sheet products, it is quite possible to get by with an appropriate hacksaw or even a file, however, thick layers can only be cut if there is an intensive impact on the structure of the workpiece. The optimal solution to this problem can be an apparatus for welding and cutting metal, operating on the principles of plasma-air processing. Outwardly, such devices resemble classic welding devices, but there are a number of significant differences.

The principle of the plasma cutter

This technique is included in the group of processing methods involving thermal effects on the material. That is, during operation, the user directs the working head of the device in order to heat a specific area. The device of this type of cutter provides for the presence of electrodes and the content of plasma gases - as a rule, compressed air is used. After starting, the plasma cutting machine begins to generate welding currents that heat the electrode. Next, the arc is activated, under the action of which the gas is converted into molten plasma. ATdepending on the model of the device, the temperature indicator of this substance can vary from 5000 to 30,000 °C.

This processing principle opens up wide boundaries for the application of the device. On the one hand, the efficiency of plasma exposure determines good performance, which is beneficial from the point of view of the use of technology in metallurgical plants. On the other hand, cutting metal with a welding machine is distinguished by high precision and accuracy, which is also appreciated by craftsmen who perform decorative processing of products.

Varieties of devices

There are two variations of such devices on the market. To use the technology in working with large volumes of workpieces, it is recommended to use transformers. This is equipment capable of cutting sheets up to 4 cm thick. The second type is inverters, which are small in size and, accordingly, have modest performance indicators. One way or another, inverter air plasma cutting machines are the most widely used, the advantages of which are expressed not only in compactness. Such devices are also characterized by the stability of the arc, which allows you to perform high-quality cuts in almost any conditions. In addition, the latest models of inverters are not so much inferior to transformers in terms of power. Senior executives, for example, allow cutting sheets up to 3 cm thick.

Main characteristics of plasma cutters

From the user's point of view, the main performance indicator is the current strength. The capabilities of the device in cutting various types of metal depend on it. Correlating the potential of the device and the characteristics of the workpiece, one should rely on the following principle: increasing the current strength increases the arc power and, consequently, the heating intensity. For example, a low-power machine for cutting metal with a current of 40 A will allow you to cope with a sheet with a thickness of 1-1.2 cm. If the power potential is increased to 160 A, then the use of equipment will be possible to work with 4-centimeter sheets.

This does not mean at all that it is necessary to focus on the maximum performance when choosing. A lot of power is not useful and will even be redundant if shape cutting is required. If the constant and purposeful use of the device for working with specific materials is not expected, then it makes sense to purchase a universal metal cutting device. Such models provide the ability to adjust the current strength, which significantly expands the range of tasks to be solved.

Plasma Cutter Compressor

Since the processing technique provides for the supply of compressed air, the compressor should also be prepared initially. In some models, it is also included in the main design, but such equipment has serious power limitations. For regular operation, an external compressor configuration is optimal. Atprovided that the pneumatic network is properly organized, such a device for plasma cutting of metal will provide both high performance and heating stability throughout the entire working session.

Hardware manufacturers

The initial segment is represented mainly by domestic models from the companies Bars, Svarog and Resanta. These are devices costing 25-30 thousand rubles, which do a good job with workpieces up to 1 cm thick. For more complex processing tasks, you should turn to models from the Fubag, Telwin, Blue Weld, etc. lines. In this case, the cost increases significantly (50-70 thousand rubles), however, the user can count on the possibility of forming a cut at a great depth. In addition, a high-class metal cutting machine will allow you to work with a large number of nozzles, which also determines the versatility of the tool.

Alternative equipment

Building technology allows cutting solid materials in many ways. But not all methods can be optimized with the expectation of being used by a mass consumer. The closest competition to plasma processing is still the classic cutting disc, which provides a mechanical effect. However, in comparison with it, thermal working elements are distinguished by accuracy and precision of processing. Recently, a metal laser cutting machine has also become widespread, which is a design in the form of a small machine. This technique is characterized by high cutting speed, precision andease of use, but its price is several times higher than the cost of plasma cutters.

Conclusion

The heat treatment method is by far the most popular metal cutting tool. Not because the tool provides the best performance. It loses to the mentioned laser machines in many parameters and is more expensive than traditional units with cutting discs. But in terms of versatility, the plasma machine for cutting metal has no competitors. The balance of technical and operational indicators makes it possible to use this tool both in everyday life and in industry. In addition, manufacturers complement the range with specialized models that are designed to perform highly professional operations.

Recommended:

Metal band saw. Metal cutting machine

Metal band saw is a high-performance equipment that is responsible for a variety of functions, such as cutting metals and cutting a variety of strong and high-strength materials

Sheet metal cutting: description, types. metal bending

Today, sheet metal cutting is one of the fairly common technological processes that allows you to get blanks of the desired size and shape. However, there are many methods for performing this procedure and a wide variety of equipment

Cutting mode for milling. Types of cutters, calculation of cutting speed

One of the ways to finish materials is milling. It is used for processing metal and non-metal workpieces. The workflow is controlled by cutting data

Metal plasma cutting

The article is devoted to plasma cutting of metal. Features of technology, tools, scopes and advantages are considered

Metal cutting with plasma. Metalworking equipment

When buying a plasma cutter, you should always prioritize quality. Beware of the temptation to buy a cheap low-quality device, as its rapid wear and tear in the long run will lead to much higher costs