2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

A properly organized electrical wiring system is an important technological characteristic of working conditions in various sectors of the national economy and industry, from small-scale welding production to energy enterprises. Not only the stability of the operation of equipment and communications, but also the safety of personnel depends on the quality of the laying of power supply lines. Busbars help to organize reliable and meet technical standards wiring, the installation of which increases the design possibilities when laying cables, and also provides a high degree of physical protection from external threats.

Preparation for installation work

By the time the technical operations are performed, the executive team should have a work plan with a design solution, which describes the scheme for assembling and placing equipment. Specifically, design documentation includes:

- Drawings of assembly units. Specifiedtype of connection, characteristics of fasteners, layout methods and options for strengthening the case.

- Equipment parameters. Since busbar trunking designs are different, a plan must be drawn up in advance to interface the housing parts with the load-bearing surfaces of the installation site. For example, solid construction models can be mounted directly to the wall using guide profiles, and some perforated versions of busbar trunking can also be mounted on hanging frames.

- Data on the required physical strength, tools and mechanisms to perform assembly and installation activities.

Regarding the preparation of busbar components, the following operations are performed:

- Checking the condition of parts for flaws and defects.

- Checking for compliance of equipment characteristics with design parameters.

- Check for completeness.

- Delivery of components to the temporary containment site before assembly or directly to the installation site.

As part of the direct organization of the installation process, workplaces are being prepared, tools and necessary fixtures are being checked at the facility.

Technology of installation of the main busbar trunking

The most difficult type of structure to install, housing high voltage power cables. For example, among the features of the installation of busbars and conductors above 1000V, one can distinguish the need to make connections by welding, the connection of special equipment for lifting assemblyblocks and preparation of supporting structures to hold the channel elements.

Work begins with the assembly of sections into modular blocks with a length of 9 to 12 m on average. The corners and nodes of the branches at this stage are carried out by resistance welding in an argon environment with semi-automatic devices. The complexity of this operation lies in the fact that this type of welding imposes strict requirements on the working environment. For example, in rooms with a high fire hazard class and in dusty areas, this connection method is excluded, so assembly is carried out in advance at other sites.

Bolt clamps when mounting a busbar for 1000 V and 1200 V are used if it is necessary to create detachable connections. Fixation is usually carried out with bolts of M8 and M10 format along the guides of the channel, in which mounting points must initially be provided for the integration of hardware. Spring washers and side metal covers are installed with the bolts.

Distribution busbar installation technology

Support structures are pre-mounted, which are then used according to the principle of load-bearing structures. At the next stage, the same arrangement of sections with blocks is performed using fasteners.

When installing the supporting infrastructure, it is recommended to maintain a distance between the supporting structures of 3-4 m, but no more. Moreover, the height should vary within 2.5-5 m, depending on the conditions in the room and the design features of the wire itself.

For docking, screw fasteners are used, whichclose the coupling halves. At the assembly stage, the connecting clamps must be in a loose state so as not to deform the structure when making hinged fasteners. In the future, the fastening force is brought to an optimal state with clamping values of 200 N or 21 kg. Also, the technology of mounting busbars of the distribution type provides for the control of docking by checking the fit of the protrusions. Coupling halves must fit into the fixing holes of the modular sections. The configuration of their placement is pre-calculated in the wiring diagram.

Despite the cumbersome design of distribution channels, they provide ample opportunities in terms of placement options. Rigid fixation, in particular, can be carried out to specially built supports, columns or to wall surfaces. With a small mass, the suspension of the channel in spans is also allowed.

Trolley busbar installation technology

The features of this type of conductive channels include their ability to ensure the movement of overhead electrical equipment, such as machine tools, crane units, roller mechanisms, etc. In essence, this is a monorail system based on steel rigid frames with channels for placing power wiring.

Installation is carried out using scaffolds or special lifts on prepared mounting structures. A system of rail tracks should be organized, in which the free passage of the target mechanism along the address contours is ensured. I-beams act as a supporting base. Themmounted to the surfaces of the ceiling or walls, which, in principle, can withstand heavy loads. The installation instructions for this type of busbar trunking state that when fixing, the minimum distance between bracket placement points should be no more than 3 m if straight installation is intended. In areas with curves or curved sections, the distance between fasteners should be no more than 1.5 m.

Particular attention during installation is paid to the technical design of service mechanics like carriages and rollers. Firstly, the lines of their movement must be clean and smooth - without protrusions, burrs and other defects. Secondly, external non-working surfaces with drive communications and the rear part of the movable mechanics are additionally closed during the installation of the busbar trunking with complete covers and couplings, under which the free space is also pre-calculated.

Connecting equipment to track busbar

Special models of busbars with track connections are designed for installation of lighting devices. They are distinguished by an optimized and compact suspension system with transitions, due to which it is possible to design current conductors of any shape and configuration. Installation and connection of track lights on the busbar are carried out in the following sequence:

- The base of the wire is fixed by installing screws into the holes made with the capture of the base panel or using a hanging bracket on cables.

- The terminal block is being installed, through which the track light is subsequently connected.

- If the block is not provided for in the design, it must be integrated using a special module that fits the format of the busbar splice.

- Connection is carried out according to the standard scheme - the capture screws are unscrewed in the well, after which the wire strands are inserted and the fasteners are restored to their previous state.

By connecting a track light on the busbar in one section, you can lay its line through the following blocks of the structure to the point of entry into the supply transformer. One central connector allows you to create branched power supply networks for luminaires distributed along long wire rails. Also, most track designs provide for the possibility of universal extension of the channel length, which is performed using special connectors.

Features of installation of open busbars

Practically all types of busbars are made in two versions - with open and closed circuit systems. The first option is a lightweight design without external protection. Such equipment is recommended to be used in places where there are no aggressive environments of external influence.

Installation is carried out according to a simplified scheme - using bolted connections, suspension cables or mounting plates to the surfaces of communication shafts. However, after the installation of open busbar trunkings, it is necessary to carry out special cable insulation. For example,areas of the busbar where exposed insulation is used should be covered with asbestos or similar flame retardant material, which will also prevent sparks from entering the wiring. External closing covers and panels are not used in these designs.

Features of installation of closed busbars

These are full-length collapsible modular shafts that cover the electrical route from all sides. This option can be used in places of increased external loads. The wiring itself at the first level of insulation is covered with a multilayer sheath, which prevents the risks of mechanical influences and electromagnetic influence. Outside, a metal case is mounted, made of aluminum or steel alloy. Reinforced mounting structures with anchor fixation can be used as fasteners for closed type busbars. Heavy enclosures are mounted by means of brackets on frames and profile mounting components. As a basis for fastening, the surfaces of capital structures, walls, ceilings and partitions are usually used. The operational features of a metal closed box include the fact that it acts as a ground loop, which can be connected to the main channels of electrical protection. In open systems, this function is already performed by special metal rods as part of the busbar trunking.

Equipment for busbar assembly and installation

The complex of installation activities provides for the implementation of seemingly typical, but still diversetechnical operations. At each stage of the work, a certain group of tools and equipment is used. In particular, the following tools and devices are used:

- Manual assembly tool. Basic tool kit including screwdrivers, hammers, pliers and other tools you will need to work with fasteners during the wire assembly process.

- Power tool. To create holes, cut excess busbars and serially tighten hardware, you will need a drill driver, a jigsaw, an angle grinder, welding equipment, a rotary hammer, etc.

- Equipment for installation of the structure. This is an additional equipment for the installation of busbar trunking, through which lifting and hinged fixation of the structure can be performed. In this capacity, traverses, grippers, winches, hoists, crane manipulators, etc. are used.

- Measuring instruments. This tool is used to check the status of the busbar's electrical infrastructure. We are talking about multimeters, testers, ammeters and other devices that measure certain indicators of wiring.

Busbar Installation Safety

During the installation process, the general requirements of the safety rules for electrical installation work, as well as special regulations related to adjustment measures for conductive modules, must be observed. These include:

- It is forbidden to use busbar structures as load-bearing members or scaffolds.

- At the time of installation onthe busbar trunking assembly and fixing area should not be visited by third parties until the hard fixing is completed.

- When organizing the technical conditions for performing fastening and connecting operations at height, you cannot use devices and devices that are not intended for safety purposes.

- Special safety requirements for the installation of busbars apply to welding. In particular, such operations should only be carried out by suitably qualified installers. Flammable objects and materials must be isolated in the welding room itself.

Conclusion

Installation of communications with busbars requires considerable technical, power and financial resources. Nevertheless, the organization of such work is troublesome, but justifies itself. The protected design of current-carrying lines extends the life of the wiring and reduces the risks when it is used in hazardous industries with aggressive working environments. The extent to which these and other positive effects will be ensured depends on the quality of the work performed. Therefore, immediately after their completion, a comprehensive check of the busbar trunking installation is carried out, during which possible defects and deviations from the design requirements are revealed. It is mandatory to revise the joints, welds, the reliability of the general fastening, the characteristics of insulators, etc. After that, test work is organized with the measurement of electrical wiring indicators and the busbar is introduced intooperational process.

Recommended:

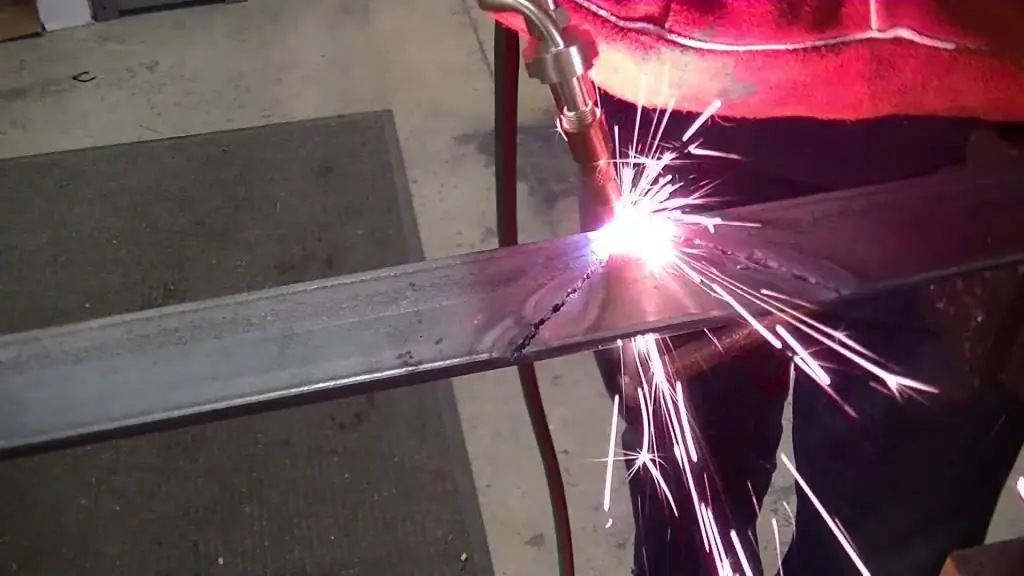

Oxyfuel cutting of metal: technology, necessary equipment, safety precautions

Oxy-fuel cutting of metals (in the literature you can find the term "oxy-fuel cutting") is actively used in industry for cutting sheet material from steel and other alloys into workpieces of the required length. The article contains information about the technology itself, about the necessary equipment and basic safety precautions for oxygen cutting of metals and other materials

Electroplating shop: description, equipment, safety requirements, harmfulness

An electroplating shop is a rather important area in any production, however, it is characterized by high danger and harmfulness. In such workshops, it is necessary to equip good ventilation, fire safety and many other protection factors

Safety explosion valve: purpose, installation

Boiler equipment, whether it is a boiler in a private house or a large boiler room in an enterprise, is a source of danger. The boiler water jacket under constant pressure is potentially explosive. To ensure safety, boilers and other heat generators manufactured today are equipped with many protective systems and devices. One of the simplest and most affordable - a safety valve installed in the heating system

Occupational safety specialist: job description. Occupational Safety Specialist: Key Responsibilities

As you know, every employee in any enterprise should have their own job description. The labor protection specialist is no exception to this rule. He, like other employees, has a number of duties and functions that undoubtedly require a detailed presentation on paper

Safety rules at technology lessons for different activities

The technology lesson is one of the favorite subjects for children, because in these classes the children learn to create, sculpt, sew, invent, where mental work is sometimes replaced by very fun things. But for a technology teacher, this is a big responsibility, since any teacher is responsible for the safety of life and he alth of children. Therefore, it is necessary to immediately acquaint students with safety rules in technology lessons