2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

The service life of pipes is reduced due to their use in conditions of low temperatures and high humidity. This problem, however, can be solved by using modern protective materials made of mineral wool. Among the huge variety of proposals on the market, Rockwool cylinders are not the last. The company started its activity more than a century ago in Denmark. During its existence, it has achieved consumer recognition.

Problem Solving

Among other market offerings, one should especially highlight cylinders that have a porous rigid structure with good resistance to deformation. During the entire period of operation, shrinkage does not occur. Therefore, all the original characteristics of the material are preserved. It has low thermal conductivity and does a good job of protecting communications from heat loss and freezing.

Description and device

The described cylinders are a material with outstanding properties, including:

- chemical resistance;

- water resistant;

- fire safety;

- easy to install.

The basis is mineral wool, which is combined with a synthetic binder. Today, this insulation is most effective in conjunction with cold and hot water supply. Rockwool cylinders can be coated with aluminum foil. The material is obtained by gluing the layers together.

Cylinders have thermal insulation properties, are easy to install, chemically resistant to acids, solvents, oils, and alkalis. They are bioresistant, easy to process with a cutting tool.

Unlined cylinders

Rockwool cylinders can be non-laminated, in which case they belong to the group of non-combustible materials according to GOST 30244-94. Foil-laminated insulation materials are low-flammable and belong to group G1. The installed layer performs the function of effective thermal insulation. Dry thermal conductivity does not exceed 0.037.

Working principle

Bas alt wool at the base of the cylinders is chemically resistant. When in contact with acids, oils, alkalis and solvents, it exhibits inertness, which allows it to be used in combination with other insulators that exhibit chemical activity. The cylinders are waterproof. Only under the influence of externalforces are filled with moisture. For the total volume of insulation, absorption is 1%.

Rockwool cylinders are fireproof. The fibers begin to melt only at 1000 ˚С, therefore they are able to endure maximum temperatures, while the thermal insulation properties do not change. The material can be used as a protective layer for structures made of combustible materials. Cylinders lend themselves well to mounting. They are easy to cut with a construction knife, and work does not take much time. If we compare cylinders at a price with other products of this type, we can single out the only minus of the described insulation.

Application

Rockwool mineral wool cylinders are supplied to the Russian market in two varieties - 100 and 150. The former withstand temperatures in pipes up to +650 ˚С, while the latter - up to +680 ˚С. These products are made with a longitudinal through cut on one side, on the opposite inner side there is a notch, which allows for ease of installation.

Rockwool coiled cylinders have an inner diameter of 18 to 219 mm. The useful layer has a thickness of 25 to 80 mm. In addition to the difference in size, cylinders can be divided into laminated and non-laminated. The former have a surface covered with reinforced aluminum foil. This material is used in industrial enterprises where there is a risk of mechanical damage, as well as for external insulation of communication systems for various purposes.

Heat-insulating coiled cylindersRockwool, non-foiled, are more often used for insulation of pipelines inside buildings, in the field of individual construction and in housing stock buildings. Areas of use are:

- external protection of the heating network;

- outdoor water supply insulation;

- Insulation of the gas pipeline outside the premises.

As for outdoor plumbing, it can be hot or cold. Cylinders protect communications from freezing, and the water temperature does not decrease during transportation. Outdoor protection is made to save energy and save heat.

Solving the condensation problem

The appearance of condensate inside the pipes can be eliminated by installing insulation of the gas pipeline outside the premises. Thus, it is possible to achieve high quality of the supplied gas. Rockwool Cylinders are insulation that comes in standard lengths of 100 cm. This is handy when calculating the amount of material needed.

Recommendations for use

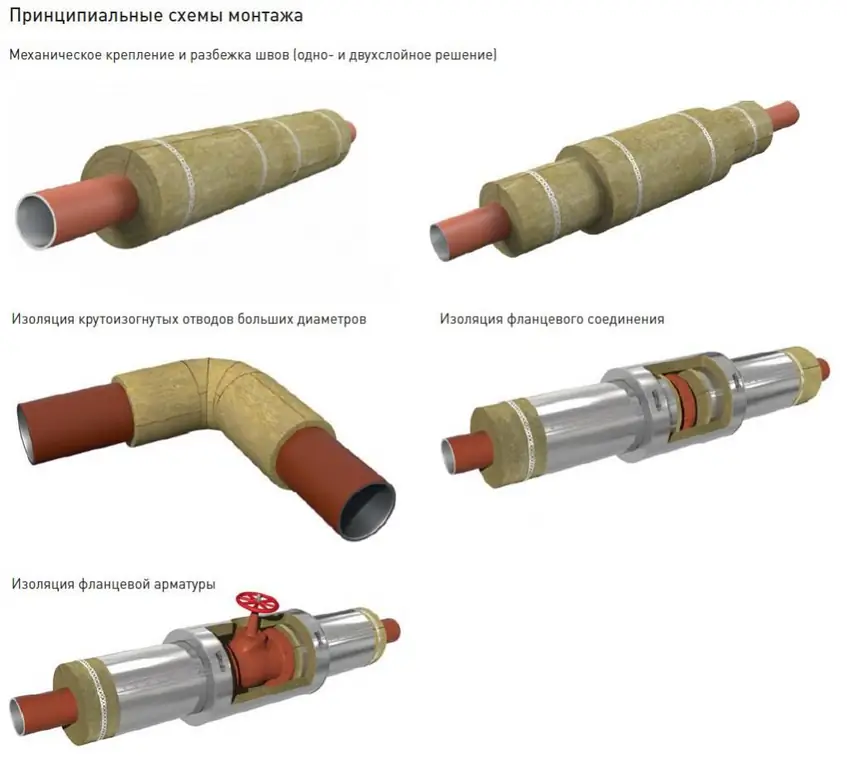

Thermal insulation is recommended to be installed from the flange connection. When mounting the cylinders, they should be adjusted to each other, providing a run-up of horizontal joints, which will ensure higher efficiency. Fixation is carried out with special bandages. If you have to work with a meter cylinder, two hoops will be enough, which are installed in 500 mm increments between each other. For installation, it is customary to use packing tape or aluminum 0.8 mm tape. It is acceptable to use black annealed or galvanized wire 2 mm. You can use stainless steel wire, its diameter should be 1.2 mm.

To isolate the outlet of communications, the products are joined end-to-end along the cut line and fixed with bandages in the amount of one piece per segment. If non-laminated products are used during the installation process, the protective coating is fastened with bandages or screws. For aluminum foil-lined Rockwool cylinders, if the surface layer is damaged, the shell is glued or waterproofed with a suitable material. It could be reinforced tape.

Quite often you have to work with pipelines in rooms with a positive temperature of the transported media. In this case, it is recommended to install foil-lined Rockwool cylinders. An additional protective layer is not required, since it is already present in the product from the factory. Products are fixed with reinforced aluminum tape.

If the cold water supply pipeline is insulated with the temperature of the transported media below 12 ˚С, it is recommended to use cylinders, additionally installing a vapor barrier layer. It is sealed at the seams. On such pipelines, a metal protective coating is usually also installed, which will exclude damage to the foil. The coating is fixed with bandages, as is the case with non-laminated cylinders.

When working on horizontal pipelines, thermal insulation can be applied without support rings. On verticalareas, to prevent slipping of the insulating material and additional protection of the coating during operation, unloading devices should be installed along the height of the pipe. They are located every 3 m. Installation of cylinders on the vertical parts of pipelines is carried out using thrust technology, which will reduce the cost and time of work. If necessary, cylinders can be used as multilayer insulation. In this case, the segments are located on top of the first layer, while it is important to ensure that the seams are offset relative to the previous layer.

Efficiency of mineral wool cylinders

On the section of the direct pipeline, heat loss with the use of the described insulation is reduced by 3.6 times. This allows you to achieve annual savings in energy costs of 20%. Installation does not require special human effort and time. The same cannot be said about rolled mats, which do not hold their shape well and provide an uneven thickness of the cover layer. This may be due to different efforts of the installer when applying the edges to one another.

When using mineral wool cylinders, human error is minimized, and a protective coating in the form of aluminum foil ensures the integrity of the insulation.

In closing

Mineral wool cylinders are designed for quick installation of thermal insulation on pipelines for various purposes. It can be communications of the gas industry, the oil field, food facilitiesenergy. This list is not complete. Mineral wool cylinders have quality characteristics that are better than products with similar properties.

Recommended:

Mobile gas station: description, device, principle of operation, application

Mobile gas station is quite a popular business idea these days. Therefore, the achievement of any success in this area can only be possible if you pay maximum attention to the various key points that are described in this article

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

General purpose engines: device, principle of operation, application, photo

Automotive equipment is mainly equipped with standardized internal combustion engines (ICEs), the design of which is focused on placement in the engine compartment. However, there is a great demand for power units of this kind in the garden equipment segments, from manufacturers of snowplows, snowmobiles, etc. Moreover, the requirements for integration and operational parameters in such cases differ sharply from automotive standards

Engine on alcohol: description, device, principle of operation, pros and cons, photo

Many people should be reproached with the inertia of the mind, which prevents them from seeing new possibilities and the application of ordinary things. For example, the engine on alcohol. Let not the best solution among all possible, but quite working. Moreover, there are a large number of embodiments. There is spirit gasoline. But not only him. Let's talk about everything in order