2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:29

It is impossible to imagine modern life without transport, regardless of whether it is personal, public or official. Therefore, every influential person tries to buy a car in order to emphasize his condition and make his life more convenient. Given the popularity of different vehicles in our time, as well as the constant fluctuations in the prices of gasoline and other types of fuel, investing in this sector can be quite profitable.

Introduction

Given the above information, a fairly reasonable decision would be to invest in this sector of the economy. One option is to purchase a filling station (gas station), which, according to many forecasts, can be quite profitable. Thus, this article will focus on the description and explanation of such a business idea as the acquisition and management of various types of mobile gas stations.

Mobile filling station general information

So, a mobile gas station is called a mobile fuel tank, which, as a rule,contains from three to one hundred thousand liters of the corresponding fuel, and the necessary system for the distribution of this fuel among various vehicles. This tank is mobile, as it is either installed on the base of the car, or made in the form of a trailer or semi-trailer.

Such filling stations are especially popular in agriculture, construction, as well as for various types of repair and road works away from large settlements. In other words, mobile gas stations are indispensable where there is a need for constant refueling of various vehicles far from civilization and stationary gas stations. In addition to convenience, mobile filling stations are also attracted by the fact that they allow enterprises to save a sufficient amount of money, since buying fuel in bulk will be much cheaper, which is quite understandable to any sane person.

Mobile filling stations set up

The device of mobile gas stations is not too complicated or incomprehensible even for non-specialists in this subject. As a rule, any mobile station includes a tank for direct storage and transportation of fuel and a fuel dispenser. In order to be able to deliver fuel to vehicles, the dispenser is equipped with a fuel distribution system, filling nozzles and a fuel consumption control display.

Because all mobile gas stationsconsidered as self-contained units, it is only reasonable that they be equipped with a petrol or diesel generator. In addition, stable fuel quality during storage and transportation is achieved thanks to the operation of appropriate filters installed inside the tanks.

Types of mobile filling stations

Despite the fact that many people are almost absolutely sure that mobile gas stations are only standard, and no other variations are provided, these installations offer a fairly large selection. These types mainly differ in size, as well as in the method of storage and distribution of fuel. A more detailed description of these species will be given below.

Container filling stations

In addition to standard mobile gas stations based on a car, there are also container gas stations (KAZS). In simple terms, a gas station is a miniature gas station that is used to service a small fleet of vehicles in a certain area. To do this, you just need to transport the fuel tank and the fuel dispenser (FRC) to the right place.

As a rule, a standard CAFC consists of the following three parts:

- storage container;

- control container;

- container store.

Based on the names of the above containers, their approximate structure and main functions should be clear without much difficulty. So, the storage container is used to store fuel in appropriate hermetictanks located inside this container.

The control container, in turn, is a kind of control point for the storage container using the fuel dispenser control controller, which is controlled by the power electrical cabinet. In addition to this controller, inside this container you can find a change house, a bathroom, radiators for heating and an impressive ventilation system. In terms of ease of use, mobile and container filling stations are very similar to each other.

As for the store container, although its presence is traditional, it cannot be called mandatory. This choice depends on the preferences of the owner who installs the gas station.

Modular petrol stations

Modular filling stations (MASs) are a subspecies of container filling stations. Their name can be explained by the fact that such filling stations are a single factory product, consisting of several ground fuel tanks. The main difference between modular and container gas stations is the fact that the former do not imply the presence of any rigid frame around the fuel tank. All the necessary elements of the fuel delivery system are located directly on the tank itself.

Despite the obvious difference mentioned above, the division between the gas station and the gas station is purely arbitrary and does not indicate any significant functional differences between different types of gas stations.

Requirements for a mobile filling stationstations

Given the fact that any type of gas station involves working with fuel that has quite dangerous properties, it is necessary to comply with certain requirements for a mobile gas station in order to avoid possible negative consequences. Compliance with these requirements is the main factor determining the safety of people who are forced to directly contact the structure of the gas station.

It should be said right away that there are a sufficient number of requirements, but only attention to all details can guarantee any positive result. First of all, it is necessary to install special sensors inside the fuel tank, which would monitor the state of tightness and signal any violations of it. Next, you should install the necessary equipment that would prevent the formation of a fuel wave when moving the gas station.

The basic rules for the operation of mobile gas stations also state that any connections of wires and cables must be equipped with additional devices that would prevent them from being disconnected. In addition, in no case is it allowed to pour fuel from the tank by gravity, that is, without the use of special devices and technologies. In conclusion, it is worth mentioning that any gas station must be on a solid surface and stand on four identical supports to ensure that the tank is level.

Requirements for gas station sites

Except for the demands that are put forwardto the gas stations themselves, there are also a number of necessary conditions that must be met from the point of view of the place where the gas station is located. If you want to locate a mobile gas station within any settlement, then it is allowed to do this only on the territory of a stationary gas station, which for various reasons is not currently operating.

At the same time, the car should drive freely along the container on one side in order to minimize possible negative consequences. In addition, the site itself must be level and have grounding to protect the PASS customers and service personnel.

In the end, I would like to say that only if all the above requirements are met, the operation of mobile filling stations will be safe and efficient.

Conclusion

Mobile filling stations are a fairly popular phenomenon in our time, which is gaining more and more popularity among ordinary citizens. Now, not only large enterprises can purchase a gas filling station to meet their internal production needs, but also individuals have the opportunity to purchase such a gas station in order to organize their own business directly related to fuel. It should be noted separately that this business plan has a great chance of success, given the current situation with prices for various types of fuel.

Recommended:

Gas pumping units: description, device, principle of operation, reviews

From primary production to direct use, gas mixtures go through several technological stages. To optimize transportation and intermediate storage between these processes, the raw material is subjected to compressor compression. Technically, similar tasks are implemented by gas compressor units (GPU) at different nodes of backbone networks

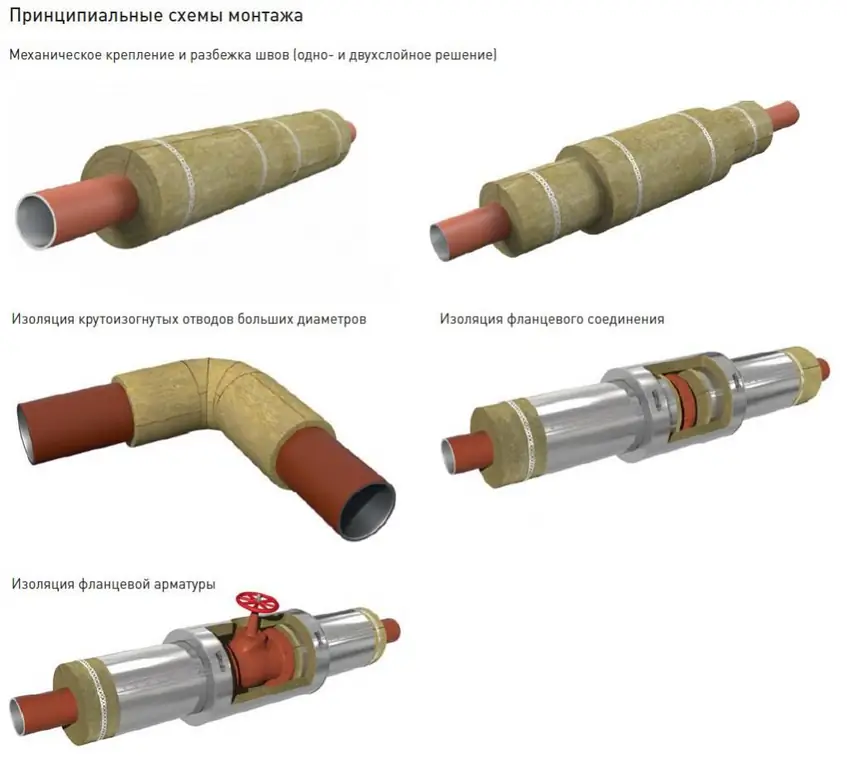

Cylinders "Rockwool" (Rockwool): description, device, principle of operation, application, photo

The service life of pipes is reduced due to their use in conditions of low temperatures and high humidity. This problem, however, can be solved by using modern protective materials made of mineral wool. Among the huge variety of proposals on the market, Rockwool cylinders are not the last. The company started its activity more than a century ago in Denmark. During its existence, it has achieved consumer recognition

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

General purpose engines: device, principle of operation, application, photo

Automotive equipment is mainly equipped with standardized internal combustion engines (ICEs), the design of which is focused on placement in the engine compartment. However, there is a great demand for power units of this kind in the garden equipment segments, from manufacturers of snowplows, snowmobiles, etc. Moreover, the requirements for integration and operational parameters in such cases differ sharply from automotive standards

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities