2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Physical properties, in particular, the hardness of any material, depend not only on its chemical composition, but also on the bulk molecular structure. A striking example is a diamond, which is made up of the same carbon atoms as a regular pencil lead. Iron can also become softer or harder, depending on how its crystal lattice is formed. This property of it has been known to people for a long time, and, as often happens, it was originally used in weapons technology.

Tempering metal has long been practiced in the manufacture of swords and sabers. The art of the gunsmith was to create such a blade that would not break in battle, would retain its sharpness for as long as possible. A knight's sword, a Saracen's saber, a Russian knight's treasury or a samurai's katana met these requirements, and their production technologies were brought to the level of high art.

Tempering of metal is done by heating it to a temperature called critical. Its value corresponds to such a state of the material, in which there is an increase in entropy, leading to crystallinechanges. To fix this position, the object must be cooled quickly enough. Of course, such a description of the process is extremely simplified; in fact, the technology is usually much more complicated. However, it is in this way that metal is hardened at home in cases where a purchased tool, for example, an ax, becomes dull too quickly. It should be remembered that this procedure cannot be repeated many times, otherwise the metal will “get tired”, its internal molecular bonds will weaken, and it will not fit for anything except for remelting.

As in any other business, here you can not rely on the principle of "the more the better." To obtain the desired properties of the object, it should be heated to the desired temperature. Unfortunately, the thermometer cannot be used. The method used for thermal control is also very ancient. The temperature is determined by the color of the glow, and when it is reached, the metal hardening passes into the next phase - cooling, for which water or oil is used.

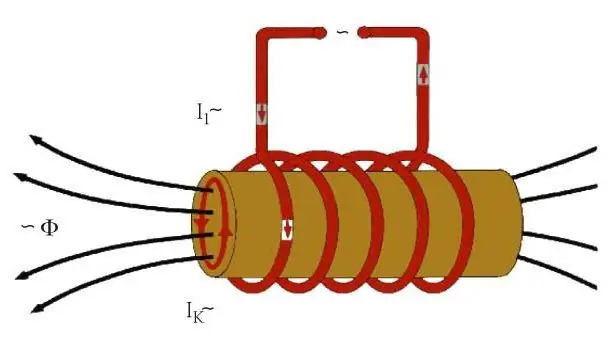

Comprehension of the effect of induction by scientists has opened a new page in metalworking technologies. It turned out that the depth of the heated layer depends on the frequency of the current.

In the diagram, the arrows show the heating zones of the part and the passage of the pickup lines.

Surface hardening of metal became possible. The part is brought to white heat not by immersion in the hearth of the flame, as was the case in the Middle Ages, but by resistive heating by currents induced by a coil that does not haveher direct contact. This technology provides unique, at first glance, contradictory properties: the product can be solid on the outside, but plastic on the inside. Surface induction hardening is used when strength is required and brittleness is unacceptable.

The author of the theoretical justification and methodology for the practical application of this technology was in 1936 our compatriot - Professor V. P. Vologdin. In addition to physical advantages, this development is also economically beneficial, since almost all the energy emitted by the inductor is used to heat the workpiece.

Recommended:

Modern production. The structure of modern production. Problems of modern production

Developed industry and a high level of the country's economy are key factors influencing the we alth and well-being of its population. Such a state has great economic opportunities and potential. A significant component of the economy of many countries is the production

How many times a day can a collector call: reasons for calls, legal framework and legal advice

If collectors call too often, it means that they are breaking the law. Consider the restrictions that apply to such calls. Can the collector call relatives and friends? Are threats from him acceptable during a telephone conversation?

How many times you can take a mortgage: restrictions and legal opportunities, mortgage conditions

Most citizens of our country are forced to take out a mortgage to buy a home. For many, this option of acquiring their own housing is the only possible one. Housing statistics states that 7 out of 10 apartments are purchased through a mortgage loan. At the same time, a logical question often arises: "How many times can you take a mortgage and what is needed to re-register it?"

What is surface hardening of steel? What is surface hardening used for?

The present article is addressed to people who are far from metallurgy, amateurs who are interested in how strength differs from a good blade in an ordinary table or folding knife, surface hardening from bulk hardening, and similar issues

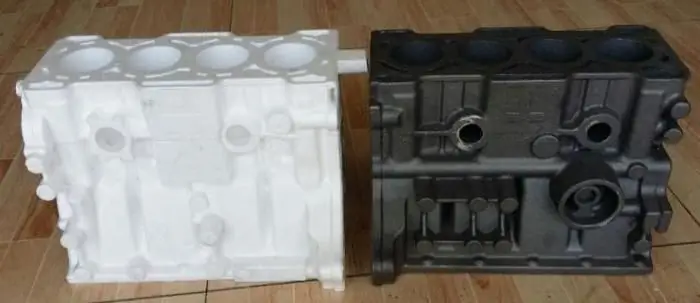

Metal casting: process, methods, methods

Metal is the basis of all modern civilization. In a year, modern humanity mines and processes such an amount of iron alone that before the whole world would have been digging it for at least a couple of centuries