2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Laying communication lines in the traditional way requires the use of special equipment that destroys the soil mass to the level of the laying. In turn, horizontal directional drilling (HDD) focuses on the method of trenchless formation of a channel or shaft into which a pipe or cable is laid. Of course, the installations used in this case perform technologically more complex actions and require more energy costs. However, there are many advantages that justify the HDD technique. The technology of drilling without creating a trench allows laying communications in conditions where the destruction of the soil surface is not allowed. This is especially true in urban areas, but the features of this drilling method do not end there.

Technology overview

The technique of drilling along a horizontal line is to form a well by cutting the soil using the corner puncture method. That is, an installation with a working head is introduced into the bowels of the earth in such a way that the surface under which it is planned to conduct a communication channel retains its integrity. Traditional method and technologyhorizontal drilling is carried out using a rock cutting tool. This is a drill bit with an emitter and a bevel. The head performs pilot drilling, and then the main part of the work is carried out through the control system with a change in the parameters of well formation depending on the requirements of the project.

A large part of the work is done even before the start of drilling. Specialists study the properties and qualities of the soil, the location of functioning communications, etc. Probing of the soil mass with the registration of other underground objects is the most important stage of preparation, after which horizontal directional drilling can begin. Technologies for monitoring possible intersection routes of the existing communication with the project one allow not only to solve the issue of access to work, but also to determine the optimal tactics and trajectory of well construction.

Correction of drilling parameters

The main difficulty in performing this type of drilling is not in the mechanical destruction of the soil, but in maintaining the correct direction of the bit. The head is controlled by correcting its position in the vertical and horizontal planes. Mechanically, this task is performed through a flexible cable. One of its ends is fixed at the end of the drill rod, and the other is controlled by the operator of the HDD complex. The drilling technology also provides for the possibility of expanding an already finished well. To perform this operation, the drill nozzle is replaced by a rimmer - this is a device that performschannel expander function with reverse action. By rotating, the unit forms the required dimensions of the shaft, at the same time pulling the pipeline.

Drilling location

Effective control of the drilling process is impossible without the use of the working head location system. Since the direct position of the crown is not monitored visually, special monitoring systems are provided, which also take into account the HDD method. The method and technology of modern horizontal wells, in particular, involve the use of location probes. These are special sensors located in the part of the drill head.

Probe communication with the operator is provided by means of a synchronization device. In this way, the user can track the location of the drill by recording information about its direction, angle and temperature. The collection of this and other data is mandatory, as it allows you to completely secure horizontal directional drilling. Traditional well formation technologies most often make it possible to control the head without the use of scanning devices. But in this case, the installation works in inaccessible zones, so the loss of control can lead to unpredictable results.

Wash mixtures and solutions

The performance of a drilling rig largely depends on the quality of the drilling fluids used. For example, such mixtures can increase the speed of the drill, improve safetyprocess and even have a beneficial effect on the environmental situation in the area of the event. To date, solutions with components that prevent clogging of the HDD unit are successfully used. Drilling technology involves the use of compounds that include lubricating additives, polymer particles, fillers that improve abrasive action, etc. Bentonite mixtures are also popular, which are easy to prepare.

Applied equipment

Machines consisting of several functional blocks are involved in the work. Standard equipment includes a running gear, a body with a frame, a power plant, a hydraulic station for servicing the mentioned solutions, a control panel, etc. A separate place in the complex is occupied by a drilling carriage, which can be represented by different designs, not to mention interchangeable heads. As far as performance is concerned, HDD technology lists the pull force of the pipeline as one of the key indicators. The parameters of the maximum length and expansion of drilling are also important.

Dignity of the method

Not always, but in many cases already during the operation of communication systems organized according to this technology, it is possible to sanitize and repair them without the need to create the same trench. In addition, in conditions of increased occurrence of groundwater, there is no need for dewatering, which expands the scope of HDD. Horizontal directional drilling, as already noted, requires the use ofmore complex equipment, however, in terms of logistics organization, this is one of the most affordable ways to create wells.

Conclusion

As new technological solutions are introduced into the construction and industrial production, end users will receive a lot of benefits. However, there is a downside to the use of modern modernized techniques and methods, including HDD. The drilling technology in this case imposes considerable responsibility on the operating personnel. Accidents in the process of work are rare, but, for example, the collapse of the channel can cause huge damage. For this reason, drilling equipment manufacturers and technologists especially emphasize the importance of conducting an initial study of the terrain and soil characteristics.

Recommended:

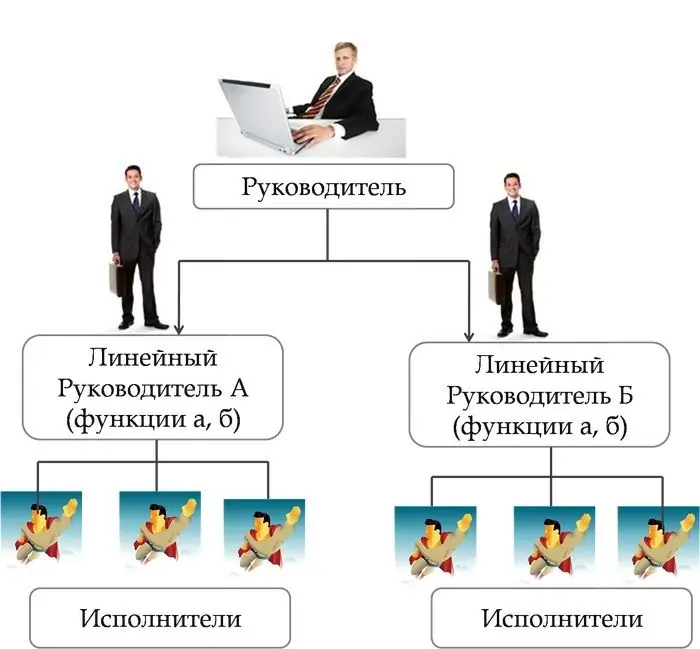

Horizontal links: concept, management structure, types of links and interaction

Horizontal connections in the management structure: general concept, varieties (functional, linear, linear-functional divisional) and their description. The main characteristics of connections and forms of their manifestation. Conditions necessary for the effective functioning of groups built according to the type of horizontal links

Horizontal communication: basic concepts, types, management methods in an organization

What is communication? External and internal business communication. Characteristics of horizontal communication, possible problems and ways to solve them. Characteristics of vertical communication: hierarchical and inverse subgroups, their description, possible problems and their solution

Horizontal division of labor is The levels of management in the organization, the concept of goals and objectives

For the efficiency of the enterprise, horizontal and vertical division of labor is used in management. It provides for the detailing of the production process and the distribution of powers between managers of different levels. In order to improve the performance of the company, it is necessary to know the principles of the division of labor, as well as correctly determine the goals and objectives of the organization

Resource-saving technology. Industrial technologies. The latest technology

Modern industry is developing very dynamically. In contrast to past years, this development is proceeding intensively, with the involvement of the latest scientific developments. Resource-saving technology is of great importance. This term refers to a whole system of measures aimed at a significant reduction in resource consumption, while maintaining a high level of product quality. Ideally, they try to achieve the lowest possible level of consumption of raw materials

Horizontal sand trap: device, features and diagram

Horizontal sand trap is one of the varieties of devices that is designed to separate mineral impurities from waste water. Such a procedure is necessary, as it helps to improve the performance of facilities that are engaged in subsequent water treatment