2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Horizontal sand trap, like any other, is designed to clean wastewater from mineral impurities. It is important to note here that the separate process for the separation of mineral and organic impurities is relevant due to the fact that in this case, the operating conditions of those facilities that are engaged in further water purification and sediment removal are facilitated.

General description of the device

The principle of operation of such equipment is quite simple. It is based on the fact that mineral particles, which are pollutants, also move along with water. Those particles whose specific gravity is greater than the specific gravity of water precipitate to the bottom. Sand traps are typically sized for water speeds that will drop only the largest mineral-type particles.

If we talk in numbers, then horizontal sand traps and any other types are designed to hold sand with a particle size of 0.25 mm or more. It has been experimentally proved that for the optimal operation of such a device, the speed of the horizontal flow of water should not beless than 0.15 and not more than 0.3 m/s. If you exceed the maximum speed of movement, then the sand simply will not have time to settle in the sand trap. If the speed is too low, then organic impurities will also precipitate along with mineral impurities, which is undesirable.

Today, two types of horizontal sand traps are used - with a rectilinear or with a circular movement of water. There are also vertical views in which the liquid moves upwards. The last type is screw devices, when using which the rotational-translational movement of the liquid is carried out.

Main parts of the horizontal device

Today, sand traps of the horizontal type are the most widely used. This equipment consists of such main working elements as the working part, in which the water flow moves, and the second part - the sedimentary one, designed to collect and store the precipitated sand until it is removed.

Calculation of a horizontal sand trap is a set of formulas that allows you to calculate all the necessary parameters. For example, the flow rate is Q=130,000 m3/day. In order to determine the flow rate of waste water per second, the following formula is used:

qsec =130,000 ÷ (243600)=1.5 m3/s

Uses a wide variety of calculations to complete the calculation.

Design features of the device

Speaking ofdesign of a horizontal sand trap, then it is a rectangular tank with a sedimentary part at the beginning. The design and modification of the sand trap greatly affect the movement of the fluid inside the device. However, despite the change in flow, the speed must always remain such that only sand is deposited, and the rest of the pollution passes on.

As for the horizontal sand trap with a circular movement of water, it is more complex in design than with a rectilinear movement of water. But at the same time, it takes up much less space, and is also more convenient to use. The sump of such a unit is made in the form of a round chute. The gutter itself is located exactly in the middle of the sand trap, and the wastewater is supplied from one side.

Rectilinear constructions

As for the horizontal sand trap with rectilinear water movement, this is the simplest design in use. In this case, structurally, the sand trap will consist of two separate parts. The first part is a walk-through where wastewater flows, and the second part is a sump for collecting sand. Most often, with this design of the unit, the sump is installed as close as possible to the beginning of the sand trap. This is justified by the fact that the maximum performance when cleaning the liquid is observed precisely at the beginning.

In order to remove sediment from the sump, grabs, hydraulic elevators, sand pumps can be used. It is worth adding that the sand is not toxic and after passingspecial procedures, it may well be used for sprinkling paths, when planting forests, etc.

Design units

If you look at the diagram of a horizontal sand trap, you can easily understand that it has a rectangular cross section. The design of such equipment is based on the exact particle size to be retained. It is worth adding here that in addition to mineral impurities, organic substances are also retained, whose hydraulic size coincides with that of sand.

When considering the drawing of the sand trap, you can see that such a device has a wide inlet and a rather narrow outlet. The bunker for collecting sediments is usually located below, under the bottom of the sand trap itself. However, in some cases, it may well be located on top - above it.

Here it is worth mentioning that there is a maximum time that wastewater can be inside the sand trap. This figure is thirty seconds. Because of this time constraint, when designing sand traps, they are always calculated based on the peak flow rate of the waste liquid. Given all these parameters, you can easily calculate the desired surface area of the device.

Based on the surface area, as well as the length of the sand trap, the width of the tank can be easily calculated. In order to constantly maintain the same speed of water movement when using a horizontal type sand trap, the pipeline is supplied with drainholes.

Additional structural elements

In addition to the details that were listed above, any device has mechanisms that are responsible for supplying the mineral phase to the sludge collection bin. All these devices are divided into two types: chain and cart. They can be seen on some drawings of the horizontal sand trap.

If we talk about the first type of device, then it is an endless chain that moves along the bottom of the bunker in the direction opposite to the direction of water movement. The return movement of the chain is carried out already above the sand trap. Sand is removed with scrapers.

As for the second type, these are small carts that move along two or one rail guide at the bottom of the unit. Sand is removed from the hopper with a scraper attached to the bottom of the cart.

Other sand removal methods

In addition to the methods described above, a hydromechanical method of water purification can be used. It is usually used in sand traps of horizontal radial or tangential type with rotary and tangential movement of sewage. Most often, such devices are used only to extract small amounts of sedimentary substances.

With this design, sand removal will take place using a pipeline that is laid along the bottom of the sand trap, and also has injection holes. Similar holes are directed to the sidebunker. In this case, the sediment, that is, sand, will liquefy somewhat, entering the semi-liquid phase. With such a movement, the substance will also carry with it the upper layers of the precipitated mineral phase. In order to additionally get rid of moisture in the sand, it is removed from the hopper using a screw-type conveyor.

Aeration devices

There are also horizontal devices with tangential type aeration. These are sand traps with the same design as the previous ones, but additionally with aerators, and the mesh size is from 3 to 5 millimeters.

Due to the aeration process, the sediment is characterized by less moisture, and it also contains fewer substances whose density is less than that of sand. These advantages are due to the fact that the flow of wastewater performs both translational and rotational motion.

You can buy horizontal sand traps "EcoTech" in Moscow. The company is engaged in the production of such devices in Russia.

Recommended:

Aircraft device for dummies. Aircraft device diagram

Few people know how an airplane works. Most don't care at all. The main thing is that it flies, and the principle of the device is of little interest. But there are people who cannot understand how such a huge iron machine rises into the air and rushes at great speed. Let's try to figure it out

Automation of boiler plants: description, device and diagram

To regulate and optimize the functioning of boiler units, technical means began to be used even at the initial stages of automation of industry and production. The current level of development in this area can significantly increase the profitability and reliability of boiler equipment, ensure the safety and intellectualization of the work of maintenance personnel

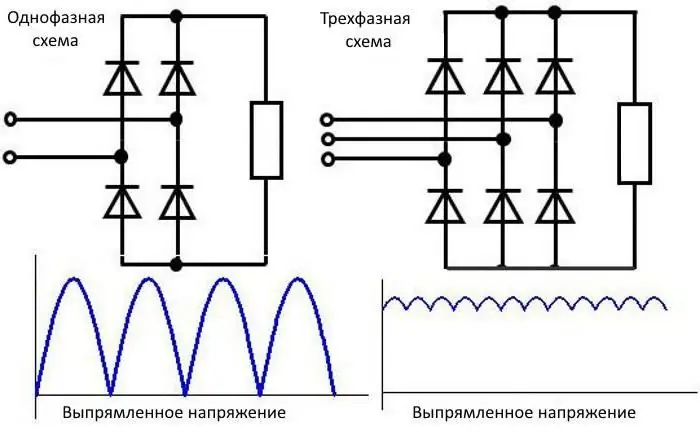

Device, principle of operation and diagram of the rectifier diode bridge

Alternating electric current is converted into a constant pulsating through the use of special electronic circuits - diode bridges. The rectifier diode bridge circuit is divided into 2 versions: single-phase and three-phase

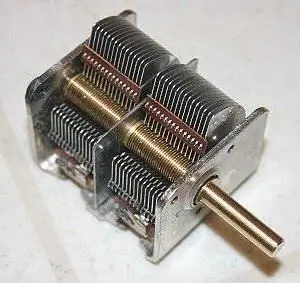

Variable capacitor: description, device and diagram

Currently, people almost everywhere use radio-electric devices and other things powered by electricity. However, few people wonder how it all works. One of the small elements is a variable capacitor, but it performs a rather important function

Brick heating shield - features, device and design diagram

The heating shield will become an indispensable assistant if such devices as a potbelly stove are used indoors. Although it is worth noting that they have a couple of rather serious disadvantages that can alienate potential users