2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Aluminum composite panels, the price of which will be written below, are mainly used when finishing buildings, houses and structures from the outside, using a special ventilated facade technology. Such material can also act as an element of washable and wear-resistant finishes for various public places, such as medical institutions, airports, restaurants and cafes, railway stations, bus stations. And thanks to simple installation, they are often used for the construction of advertising structures.

Production

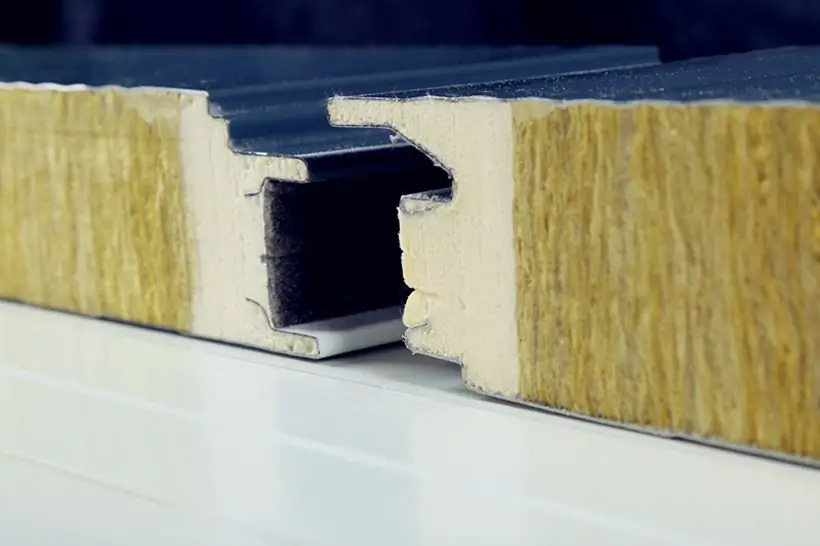

Composite panels are made by bending aluminum sheets, and the radius of curvature should be as small as possible. The latter, subject to all the necessary regulatory standards, is absolutely similar to the thickness of the plate. Right anglerelative to the main surface, special installation bends are bent along the entire perimeter of the panel. These folds are then placed in a special installation profile, which is attached to the wall surface and snaps into place very firmly.

Classification of mounting profiles

All modern mounting profiles are divided today into 3 main varieties:

- joint with seal;

- open panel docking;

- using a waterproof screen.

In order for the facade to acquire enhanced rigidity, additional elements are often used. For example, wooden beams or flat shields can be used as props.

Benefits

The main advantages of aluminum composite panel surface finishes are a wide range of different colors and a long service life of the front side of the painted material. Another positive quality of such products is the ease of various processing processes, in particular, milling. It is she who allows you to create technical holes on the surface of products. The density of the aluminum panel is approximately 6 kilograms per square meter.

Flaws

It is worth noting that this material does not apply to thermal insulation, since it is made for the most efficient heat transfer. It allows you to equalize the temperature of the inner and outer aluminum sheets, otherwisewhen this material is heated in the sun, severe deformation may occur.

In order to avoid the so-called cold bridges, the installation of aluminum composite panels must be carried out in such a way that special paronite thermal breaks are laid between the surface of the load-bearing wall and the brackets of the installation guide elements.

Scope of application

Most often this product is used to create the exterior of certain buildings. The most popular are ventilated facades. However, this is not only the scope of this material. Aluminum composite panels are also used in interior decoration, for example, in public institutions. As a rule, these are schools, railway stations, theaters, salons, shops, centers. That is, these are premises where a large flow of people constantly passes. After all, it is in such buildings that resistant materials should be installed that are not afraid of mechanical damage. They will not only be a powerful support, but will also be a good decorative finish.

Also very often aluminum composite panels are used in places of temporary exhibitions or on billboards. They are ideal for the restoration of old houses, especially those whose walls cannot be restored. Thanks to these panels, complete sound insulation will appear, and the appearance will become much more attractive.

Installation errors

In order for the panels to serve for a long time and not quickly deform, it should be observed during installationcertain rules. When the sheets are delivered, they should be inspected for scratches or defects.

In order for aluminum composite panels not to be damaged during storage, it is necessary to install cardboard or any other material of similar texture between them. Ideally, if the sheets are planned to be transported by crane, it is best to use special clamps that will give a high guarantee of product safety.

When installing, the main thing is to remember some properties of the panels. For example, when the temperature rises, their dimensions slightly increase. This suggests that when laying it is necessary to leave very small gaps between them. Backlash is welcome.

The protective film should also be removed without errors. Aluminum composite panels, the price of which starts from 1 thousand rubles per 1 sq. m, it is easy to bend as a result of incorrect movements. You need to remove it at an angle of 180o. And only after 2 weeks, or better, even a month after their production. It is in this case that the glue will be removed completely, and will not remain on the surface.

Goldstar

Aluminum composite panel, which manufacturers sometimes use the wrong technology and do not apply a protective layer, it is better to buy the Goldstar brand. Maybe some are scared that they are made in China, but in fact, if you buy authentic models, the quality is really amazing. According to people's opinions, it is they who lend themselves best to long-term operation and withstand mechanical stress. Branches of this company can be found in various countries, includingAmerica, Europe and Asia. It should be noted that the prices for Goldstar aluminum composite panels are not so high and differ little from competitors' prices. What confirms the quality of these materials? And the fact that in New York some skyscrapers are built with the help of this particular product. This speaks of the invaluable quality of the panels and the honesty of the manufacturer, which is now so valued in the world market.

Producers

Alcan Kapa GmbH is a German company that started its activity in the 60s. Its products belong to the category of quality products, which are in great demand. However, one must be prepared for the fact that there are many fakes on the market that pass off as a German product.

Alufas is a Ukrainian trade mark specializing in the production of composite panels. The plant is located in the city of Dnepropetrovsk, equipped with high quality equipment. During the manufacture of panels, the latest technologies are used. That is why there are no analogues of this brand in Ukraine.

There are also other manufacturers on the market, such as Reynobond, Etalbond (Europe), Alpolic (Japan) and others.

Result

Based on all the information, we can say that aluminum composite panels are an excellent material, which today is a leader in the construction industry. It is great for decorating any buildings, because its excellent appearance and good performance are its not detachable advantages. Thanks to thismaterial can make your existence more colorful and comfortable. Moreover, the panels do not require maximum maintenance.

Recommended:

Corrosion of aluminum and its alloys. Methods for combating and protecting aluminum from corrosion

Aluminium, unlike iron and steel, is quite resistant to corrosion. This metal is protected from rust by a dense oxide film formed on its surface. However, in the case of destruction of the latter, the chemical activity of aluminum greatly increases

Solar panels on the roof: description, installation methods, principle of operation, reviews

Until recently, the use of sunlight as a replacement for traditional energy sources was perceived as something fantastic or possible only under special conditions. Today, such solutions do not look incredible, but the problems of their implementation in practice for ordinary consumers also remain. By itself, the installation of solar panels on the roof is quite simple and optimized, but this does not eliminate the difficulties in organizing the operation of such batteries

Thermal conductivity of sandwich panels: concept, main characteristics, dimensions, thickness, thermal conductivity coefficient, installation rules, pros and cons of operation

Thermal conductivity of sandwich panels will be the lowest if polyurethane foam is the basis. The parameter under consideration here varies from 0.019 to 0.25. The material is strong, dense and light. It is chemically resistant and does not absorb moisture. Rodents are indifferent to polyurethane foam, fungi and mold do not develop inside it. Working temperature reaches +160 ˚С

Cable manufacturers: types of cable, list of manufacturers, rating of the best, product quality, addresses and customer reviews

Cable is such a demanded product that it is manufactured in any state. Wires are found in rooms, the ground, industrial facilities and even air. If a country is not able to guarantee itself a similar product, it is worthless. The article deals with domestic cable manufacturers

Glass matting paste: an overview of the best manufacturers and application features

Mattifying glass pastes are produced today by many companies. Most of the products of this type supplied to the market are of good quality. But the most popular brands of pastes in Russia are still Aqua-Color, Sammaker, Velvet Class