2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-06-01 07:12:56

When developing pits, excavations and embankments, it is advisable to use a bulldozer set of equipment if the average range of longitudinal or transverse hauling does not exceed 100 meters. To choose the most optimal model of special equipment, it is necessary to compare the performance of bulldozers with different traction classes and different types of working equipment.

The most promising are tracked vehicles. Equipment on pneumatic wheels is less in demand. When calculating the productivity of an earthmoving machine, it is necessary to take into account the conditions of the terrain, the nature of the work and other factors.

Bulldozer Basics

Bulldozer is an earth-moving machine for layer-by-layer excavation and transportation of soil, developed on the basis of a caterpillar or pneumatic wheeled tractor with interchangeable attachments - a blade (a flat shield with side flaps), a frame and a control mechanism.

The technique with fixed andswivel blade. In the first case, the working equipment is located perpendicular to the longitudinal axis, which allows you to move soil masses only in front of the machine. The productivity of bulldozers with a rotary blade is much higher, as such specimens are able to move the soil to the side at an angle of 60 degrees, which allows for rough grading work.

The blade control mechanism can be cable-block and hydraulic. The second type of control is more productive, as it allows you to force the dump into the ground.

Traction class machines

With the help of bulldozers, up to 40% of all earthworks on a construction site are carried out. They are most effective at an average range of longitudinal and transverse carriage from 100 to 150 meters. When machines are equipped with special shovel-type dumps, the effective range of hauling sandy soils increases to 200 meters.

The main parameter that affects performance is the traction class - the force with which the bulldozer can push the soil forward. The technical characteristics of the machines affect the volume of the moved earthen mass, the speed of work. According to this parameter, all bulldozers are divided into three groups:

- Lightweight, pulling force of which does not exceed 60 kN. They are used during preparatory, agricultural and auxiliary work.

- Medium, with pulling force 100-150 kN. Used to develop 1-3 groups of soil with preliminary loosening.

- Heavy, the pulling force of which exceeds 250 kN. They areused in the development of dense and hard rocks.

Bulldozers are used in combination with other earth-moving machines. They can be used as pushers for self-propelled and trailed scrapers. Usually, a bulldozer set of equipment includes a rammer and a ripper.

Factors affecting performance

When calculating the performance of bulldozers, it is necessary to take into account the physical and mechanical characteristics of the developed earth massif, as well as local conditions. The main physical and mechanical characteristics of the soil include:

- granulometric composition - the ratio of soil particle sizes by weight;

- density - the mass of soil per unit volume;

- porosity - the number of voids between grains, expressed as a percentage by weight;

- plasticity number - the range of moisture in which the soil has plastic properties and does not go into a fluid state;

- swelling - the ability of an earth mass to increase in volume when waterlogged;

- angle of internal friction - resistance of soil particles to shear.

Local conditions that affect the performance of bulldozers include the nature of the relief and the technological features of the construction site. In a flat and straight area with a minimum range of cross-carriage, the speed of work is much faster than in a hilly area.

Calculating the performance of bulldozers

The performance of a bulldozer depends on the type of work being done. It can beexcavation and transport or planning work. In the first case, the productivity is expressed in m3/h, in the second - m2/h. Let's dwell on earthmoving and transport works.

Operational productivity is determined by the amount of land that special equipment is able to develop and move per unit of time, that is, in one hour. The calculation of the performance of the bulldozer is carried out according to the formula

To calculate the performance as close as possible to the real one, correction factors are introduced:

- ky - the influence of the slope of the ground area. While working on slopes from 5-15%, the value increases from 1.35 to 2.25; when developing soil on the rise, the coefficient decreases from 0.67 to 0.4;

- kin - value that takes into account the time of using the machine (kin=0, 8-0, 9);

- kn - filling factor of the geometric volume of the drawing prism (kn=0.85-1.05).

To calculate productivity, you also need to know the volume of the drawing prism (Vgr) and the duration of the machine's working cycle (Tc).

Calculate the volume of the drawing prism

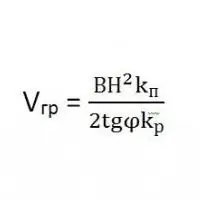

A characteristic feature of the operation of the machine is the fact that the bulldozer bucket moves the soil in the so-called drag form. In this case, the volume of the prism is calculated by the formula

Here B and H are the length and height of the dump, respectively, kn coefficienttaking into account the loss of land during its movement, is taken equal to 0.85-1.05, kр - the degree of soil loosening.

Cycle duration

To calculate the duration of the working cycle, that is, the time that the tractor-bulldozer will spend on developing one layer of soil, it is necessary to understand that the entire length of the longitudinal or transverse carriage is divided into several segments. The duration itself is calculated using the formula

Here lp, l and lo =l p+l are the lengths of cutting sections, movement of the soil mass and reverse motion of special equipment, and vp , v and vo are the maximum possible speeds in these sections. The coefficient tntakes into account the time that the driver spends shifting gears during work. Usually it is 15-20 seconds.

Performance of a bulldozer with wedge operation

The use of the wedge digging scheme is possible only with those machines that are equipped with a hydraulic blade control mechanism. Such, for example, is the Shantui SD32 bulldozer. A distinctive feature of this excavation principle is the fact that the cutting force gradually decreases as the drag wedge increases.

At the beginning of work, all the forces of the machine are aimed at immersing the blade into the ground to a maximum depth hmax and cutting the earth mass. As you move, the soil accumulates beforebulldozer, which increases the resistance to movement. For further work, the operator must increase the applied traction force or reduce the depth of cut.

Earth chip thickness

Most often they resort to the second option, but in this case, part of the land is "lost" in the side rollers (which is also bad for the "Shantui" bulldozer). To compensate for these losses, the machine must cut off “chips” along the entire path of movement, which is calculated by the formula

Here kp - correction for loss of soil during transportation, kpr drag prism coefficient, which is taken from the operational characteristics of the machine, Lp - the length of the section on which the soil is cut. It is defined as the ratio of the volume of the drawing prism to the area of the developed area.

Effect of blade type on performance

Depending on the characteristics of the soil, as well as on the tasks assigned to the bulldozer, it is advisable to use certain types of blades. This will reduce the time of work, as well as increase the efficiency of special equipment.

Any machines are equipped with a replaceable blade, including a Japanese-made Komatsu bulldozer. Among the main types of working equipment it is worth highlighting:

- reclamation subspecies, which is used to remove the top fertile layer of the earth, chernozem;

- a variety for moving coal and wood chips - used in the development of minerals, has a hemispherical shape andhydroperiscope;

- "peat" variety has a reduced height, but increased length and are used to enrich agricultural fields;

- dumps for site preparation - brush cutters and stubbers, which are equipped with teeth, are produced in a V-shape and are designed to clear the area from trees and shrubs.

The most progressive (in terms of the possibility of installing various working equipment) is the Japanese Komatsu bulldozer. All models of special equipment can be equipped with any of the blades presented, which gives them high functionality and makes them universal machines for a construction site.

The calculation of the performance of the bulldozer must be carried out to reduce the cost of earthworks. Based on the data obtained, you can choose the most optimal special equipment for work, reduce the time of work and save a lot of money.

Recommended:

Personal income tax accrual: calculation, calculation procedure, payment

In the framework of this article, the basic characteristics of personal income tax, the basis for its calculation, and the use of tax deductions are considered. Organization of accounting. Payment options are presented for both individuals and individual entrepreneurs

Calculation of average earnings upon dismissal: calculation procedure, rules and features of registration, accrual and payment

To get confidence in the correctness of all accounting calculations upon dismissal, you can easily do all the calculations yourself. The calculation of the average earnings upon dismissal is carried out according to a special formula, which, with all the features, is given and described in the article. Also in the material you can find examples of calculations for clarity

Calculation of northern allowances in the regions of the Far North: calculation procedure, determination of size, coefficients

Which regions are considered the Far North according to the legislation updated in 2018? What acts regulate northern allowances? Basic rules for calculating these surcharges. Four groups of localities - four sizes of allowances. Features, conditions, procedure for their accrual to young professionals, indigenous people, citizens over 30 years old, military personnel. Is there a connection with the district coefficient?

What is performance: concept, criteria and performance indicators

To build a system of staff motivation and to improve management, it is necessary to understand how efficiently employees and managers work. This makes the concept of efficiency extremely relevant in management. Therefore, you need to know what performance is, what are its criteria and evaluation methods

Vacation calculation: formula, example. Calculation of parental leave

In the framework of this article, we will consider the basic rules for calculating vacation pay for an employee, including in various interpretations: on maternity leave, for child care, upon dismissal, as well as for harmful working conditions