2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Bor Glass Factory was founded in 1930. Today it is the undisputed leader in the domestic auto glass market. The company's products comply with international standards. The main shareholder is AGC Group. Production is actively developing, the construction of triplex production buildings in 2006 raised the characteristics of products to a new level.

Historical background

In the early 1930s, a large-scale production of sheet glass was launched in the city of Bor, Nizhny Novgorod Region. The company quickly became one of the industry leaders. With the development of mechanized transport, the question arose of organizing a specialized production of first windshields, and then side and rear windows.

Manufacture of triplex-class automobile boron glass at BSZ was mastered in 1940. Initially, a celluloid base was used as a protective layer, over time it was replaced by polyvinyl butyral film and polymers.

Since 1948, stalinite has been produced - tempered glass with specialproperties. When splitting, it shatters into many small fragments that do not have sharp traumatic edges. They glass the rear and side windows of vehicles.

Modernization in 1970 with the installation of German equipment from Sack made it possible to produce the best quality multi-layer auto glass. The Bor glass factory has become the undisputed leader in the production of this type of product in the socialist bloc.

New stage

With the acquisition in 1997 of the shares of the Bor plant by the Glaverbel transnational corporation, the company's position has noticeably strengthened. Significant finances were directed to the reconstruction of technological capacities.

Later the AGC Group became the owner of BSZ. In the period 2006-2009, three additional lines for multilayer windscreens were built. The Added Value Operations Center and the Control Center were created.

Technology

In recent years, a comprehensive modernization of technical processes for the manufacture of boron glasses of various brands has been carried out. In the 2000s, large investment projects worth more than $50 million were implemented. In particular, a cold repair of the second and then the first float line was carried out. Today, BSZ has the most advanced equipment in the Russian Federation.

The technological process of making float glass consists of:

- preparation of returnable cullet and charge;

- glass melting;

- Glass ribbon forming;

- annealing;

- cutting, cutting into formats.

Production

The production of products for vehicles (road, rail) is the leading direction of the BSZ. Triplex Bor windshield is produced on three specialized lines. It complies with Russian, Japanese, American, European standards. The quality of the tempered rear and side windows is not inferior to international counterparts. The total productivity is 1.4 million car sets annually.

In the Russian Federation there are 9 distribution centers for product promotion, 38 auto glass replacement workshops. Bor glass is supplied to auto giants such as Mercedes, Mitsubishi, AvtoVAZ, GAZ, Volvo, VW Group, Toyota, Ford, Daimler, KIA, Renault, Citroen, Nissan, Peugeot and others.

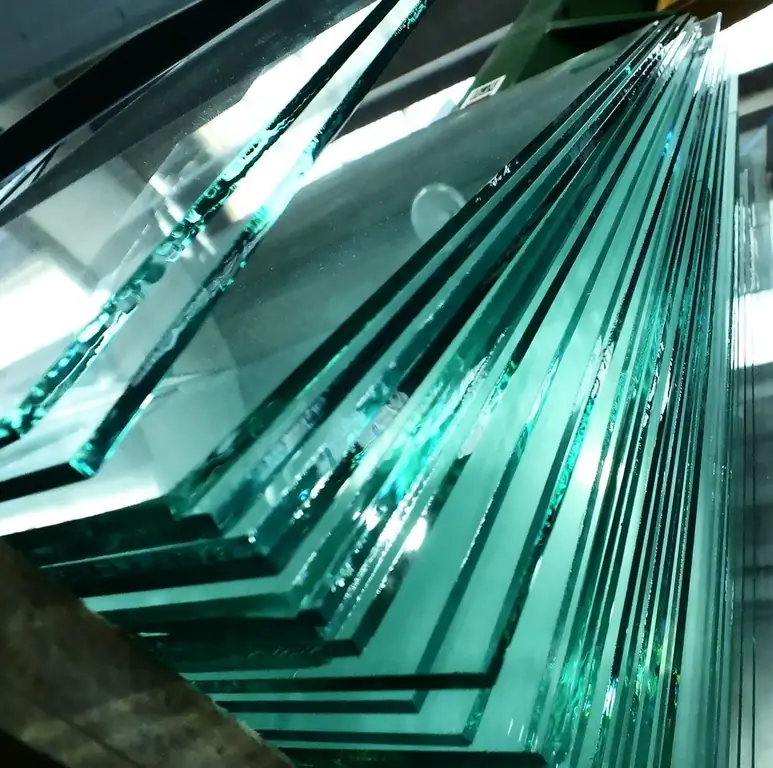

In addition to automotive glass, the Bor Glassworks carries out large-scale production of building flat glass. Two state-of-the-art float lines produce about 1200 tons of products per day. This glass is widely used both in the construction of housing and in large urban projects. AGC Borglassworks products were used in the construction of Moscow City, the Skolkovo Innovation Center, Kazan Universiade facilities, Olympic facilities in Sochi, airports in Novosibirsk, Moscow, Adler, Yekaterinburg, Krasnodar.

Products

Bor Glassworks has State Standard certificates for glass production:

- automotive (triplex, tempered);

- bulletproof;

- spherical with mirror finish;

- leafy.

Multilayer safety triplex consists of 2-3 sheets of polished glass, between which there is a photocurable composition or polyvinyl butyral film. The interlayer cushions impacts, prevents cracks from spreading, and holds fragments.

Tempered boron glass is obtained by heat treatment and subsequent uniform air cooling. The material acquires increased strength, in case of destruction it crumbles into safety fragments.

In addition to basic functions, glasses are endowed with special properties that increase the comfort, safety and durability of products. BSZ produces the following types of innovative glasses:

- Energy saving.

- With IR and UV filtering.

- Sound absorbing.

- IRIS class wind reflectors.

- With light transmission regulation.

- With heating elements, heating cover.

- Electro-thermal anti-fog.

- Fluorine water repellent door.

Recently, "smart" glasses have been developed, which display useful information for the driver. Eye-level indicators keep your eyes on the road. Also useful elements are built-in or printed antennas for communication, receiving radio and television signals.

Recommended:

How to make glass? Glass production technology. glass products

Glass is familiar to everyone. But the process of making it is extremely exciting. Each stage is important and affects the quality of the final product. The basis is sand, soda, lime. The process is almost entirely automated. Surprisingly, glass can even be made at home

Glass sandblasting: glass processing description, equipment, application, photo

Among the numerous variations of interior decoration, sandblasting of a glass or mirror surface occupies a special place. This technology involves exposing the canvas to sand or other abrasive with a jet of compressed air released under high pressure. As a result, the surface changes and becomes matte, rough, velvety or painted with patterns. In the article we will consider what is sandblasting glass

Grinding car glass. How to grind glass

The article is devoted to glass grinding. The grinding procedure, its tasks, technique, materials, etc. are considered

Glass factories in Russia. glass industry

The glass industry occupies an important place in the country's economy. Glass factories in Russia operate in almost every region. Window panes and portholes, bottles and dishes, household and interior items - without these items it is impossible to imagine modern civilization

Dmitrovsky glass factory. Enterprise activity

One of the most demanded enterprises engaged in the production of glass containers is the Dmitrovsky plant. Customers speak positively about the quality of the finished product. You will learn about the activities of the plant from the article