2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:39

Polypropylene, whose melting point should be known to you if you plan to use the material for personal use, is a thermoplastic synthetic non-polar polymer that belongs to the class of polyolefins.

For reference

Polypropylene is also known as a product of propylene polymerization. The material is white in color and has a solid structure. It is obtained by the polymerization of propylene. Polymerization is carried out under pressure of 10 atmospheres, while maintaining a temperature within 80 °C.

Molecular structure and melting point

Polypropylene, whose melting point will be named below, is divided into three types according to the type of molecular structure:

- atactic;

- syndiotactic;

- isotactic.

Atactic polypropylene is a rubber-like material that has a high degree offluidity. Its melting point is 80 °C, while its density is 850 kg/m³. This material is also characterized by high solubility in diethyl ether.

Different in its characteristics from the above described isotactic polypropylene in that it has a high modulus of elasticity, its density reaches 910 g / m³, while the melting point is much higher and varies from 165 to 170 ° C. This material is chemical resistant.

Physical and mechanical properties and specifications

Polypropylene, the melting point of which was mentioned above, differs from polyethylene in its lower density, which is 0.91 g/cm³. This value is common for plastics. The described material is also harder, which is manifested in the fact that it has a high resistance to abrasion.

Among other things, polypropylene is heat resistant, because it begins to soften when the temperature reaches 140 ° C. The melting point is 175 °C, in addition, the material is practically not subject to corrosion cracking. Polypropylene is resistant to light, as well as to oxygen. The introduction of stabilizers reduces the sensitivity even more.

Polypropylene, whose melting point you may be interested in if you plan to use this material, will behave differently when stretched depending on the temperature and rate of application of the load. The lower the stretching rate, the higher the value of mechanical properties. Atin tension, the breaking stress varies from 250 to 400 kgf/cm², while the elongation at break is limited to 200 to 800%.

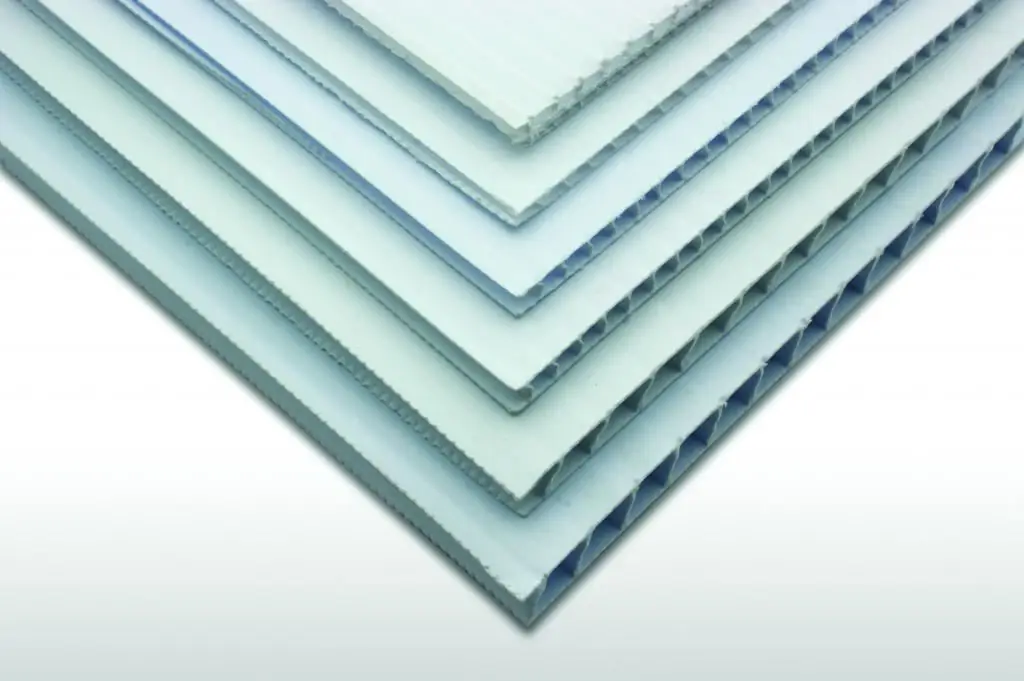

The melting point of polypropylene sheet, which was mentioned above, is not the only characteristic that private consumers are interested in. They are sometimes also concerned about the flexural modulus. In the described case, it can vary from 6700 to 11900 kgf. At the yield point, the relative elongation is equivalent to 10-20%. Impact strength with a notch is 33-80 kgfcm / cm². Brinell hardness is 6-6.5 kgf/mm².

Scope of application

The use of polypropylene is quite wide. The material is used for the manufacture of films, this includes their packaging varieties. Among other products, it is necessary to highlight:

- bags;

- pipes;

- plastic cups;

- tare;

- details of technical equipment;

- household items;

- electrical insulating material;

- non-woven fabric.

In construction, polypropylene has also found its application, where it is used for vibration and noise insulation of interfloor ceilings, as well as in systems that are equipped using the "floating floor" technology. When polypropylene is copolymerized with ethylene, a non-crystallizable copolymer is obtained. It is able to exhibit the characteristics of rubber, which has aging resistance and superior chemical resistance.

For heat and vibration isolationexpanded polypropylene is widely used. The melting temperature of sheet polypropylene was mentioned above, however, this characteristic is not the only one that you should be interested in before purchasing products from this material. You should also know that polypropylene foam is very close in properties to polyethylene foam. But expanded polystyrene can be replaced with a decorative extrusion profile made of polypropylene foam. Atactic polypropylene is often used to produce putties, road surfaces, building adhesives, mastics and sticky films. The scope of polypropylene in Russia was as follows:

- 38% - container;

- 30% - threads;

- 18% - films;

- 6 % - pipes;

- 5% - polypropylene sheets;

- 3 % - other.

Melting point of polypropylene pipes

The melting point of polypropylene pipes is one of those characteristics that are most often of interest to the modern consumer. This material will begin to soften at 140 °C, while melting at 175 °C. The last parameter is the superheated steam temperature. Given this number, polypropylene could be used for any plumbing system that transports water at an arbitrarily high temperature.

But in this matter, everything is not so simple. Plasticity is an additional feature of the material. At break, polypropylene has a relative elongation that varies from 200 to 800%. This indicates that if a certain weight is applied to the pipe, the product will stretch into a long tube, and then break.

As a conclusion: the nature of polypropylene

The properties of polypropylene, the characteristics and nature of this material will allow you to understand in which area it is best to use it. Isotactic propylene is considered the most popular in production today. This is due to the peculiarities of this type of material, where CH3 side groups have a special position, located unusually with respect to the main chain. Such a sphere has determined the main qualities, among them should be highlighted: the ability to maintain shape when exposed to high temperatures, hardness and high strength.

Recommended:

Steel 09G2S - properties and characteristics

Diversity in the steel industry is often intimidating for people who need to purchase a particular grade of steel for a specific need. This problem is solved by a long and methodical study of the topic, understanding its very essence. However, there is a way to cut a little. This article contains all the most important and useful information regarding steel 09G2S. Reading this article will not take much time, and the knowledge gained will help you choose the right material

Polypropylene - what is it? Definition, technical characteristics of the material, application in industry and everyday life

You can build a heating system with your own hands from polypropylene. The material is affordable and lightweight. Before starting work, it is necessary to designate the connection points and understand the installation method. For soldering pipes, products must be cut to size. The joints must be even and have a right angle. Sections are degreased, chips are removed from the surface after cutting

Polypropylene thread: types, characteristics and applications

With the growth of the consumer market, the demand for packaging products has increased. It turned out to be unprofitable to make them from natural materials. Manufacturers have begun to use synthetics, which are more convenient to use and simplify the production process, making costs minimal. Polypropylene thread has become one of the types of such products. It can be used in almost all packaging materials

Two-component polyurethane sealant: definition, creation, types and types, characteristics, properties and nuances of application

With long-term and high-quality sealing of seams and cracks, polyurethane two-component sealants have found their wide distribution. They have high deformation and elastic properties, therefore, they can be used as butt sealants in the field of repair and housing construction

Polypropylene fibers: composition, properties, application

Polypropylene fiber has found wide application in modern industry. This inexpensive material with excellent performance is used to make car brushes for cleaning roads, furniture upholstery, fillers, etc