2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Polypropylene is quite common today in various fields of human activity. What it is, you can find out by reading the article. This substance is indicated by two large letters PP and is a thermoplastic polymer of propylene, which is also called propene.

Definition

It is obtained by the method of propylene polymerization with the participation of metal complex catalysts similar to Ziegler-Natta analogues. The parameters required for the formation of polypropylene are close to those required for the production of low pressure polyethylene. Depending on which catalyst is used, any type of polymer or a mixture of them can be obtained.

If you are interested in polypropylene, what it is in terms of chemical characteristics and general properties, you should know that the substance has the form of a white powder or granules. The bulk density of the latter varies from 0.4 to 0.5 g/cm³. The substance is produced colored andunpainted, stabilized.

Specifications

If we compare polypropylene with polyethylene, the first one is less dense, for this substance this indicator is 0.90 g/cm3, which is the smallest value for plastics. The material is harder, it is heat-resistant, resistant to abrasion, softening begins at +140 ˚С. The melting point is +175 ˚С. The material is virtually immune to stress corrosion cracking.

When studying the question that it is polypropylene, you should know that it is resistant to light and oxygen, but this characteristic is reduced by the introduction of stabilizers. The tensile behavior of a substance depends on the temperature and the rate of application of the load, which manifests itself to a greater extent than that of polyethylene. With a decrease in the stretching rate, the index of mechanical properties increases. When this parameter is quite high, the breaking stress becomes below the tensile yield strength.

Additional Features

Polypropylene exhibits chemical resistance. It can be strongly affected only by oxidizing agents such as fuming nitric acid, oleum, chlorosulfonic (sulfuric monochloride) acid or halogens. 30% hydrogen peroxide and concentrated 58% sulfuric acid act very slightly and at room temperature. Contact can be maintained with these reagents without degradation of the polymer if the temperature is in the range of +60 ˚C or lower.

Polypropylene swells inorganic solvents at room temperature. If the temperature is above 100 ˚С, then the material dissolves in aromatic hydrocarbons like toluene and benzene.

Use in industry and everyday life

Today, polypropylene is very common. What it is and how to use the material, you can understand if you take a closer look at the areas of its application. Raw materials are used for films, pipes, containers and parts of technical equipment. Household items and various non-woven materials are made from it. It forms the basis of electrical insulating materials, and in construction it is used to make noise and vibration insulation of floors between floors.

Polypropylene has found its wide distribution in the formation of the "floating floor" system in everyday life. Non-crystallizable copolymers are obtained by polymerization of propylene with ethylene. As a result, the material acquires the properties of rubber and has an increased chemical resistance. During operation, it effectively resists aging.

Best solution

If you want to choose the best polypropylene, you should understand the issue from different points of view. Among other market offers, you can find polypropylene pipes from different manufacturers. Only positive feedback was received by German-made products, among other companies from Germany, it should be noted:

- Rehau;

- Aquatherm;

- Banninger;

- Wefatherm.

Czech pipes occupysecond place, among them ECOPLASTIC and FV-Plast stand out. The cheapest and inferior in quality products are Turkish-made pipes, you can recognize them by one of the following names:

- TEBO;

- Vesbo;

- FIRAT;

- Jakko.

China is not happy with the quality, but in this rule, as in any other, there are exceptions. Chinese polypropylene pipes BLUE OCEAN have proven themselves well. You can also choose the best products for other features. Products are single-layer and multi-layer. The latter allow to reduce thermal elongation and are reinforced with foil. Such pipes can be perforated or smooth.

You can also choose a high-quality polypropylene pipe based on the type of reinforcement. Sometimes the foil layer is located on the outside. Another type of reinforcement is an internal aluminum layer. It allows you to connect layers without the use of glue. Fiberglass is also used for reinforcement.

Pipe diameters

In order to get even better acquainted with polypropylene, you should find out what diameters of pipes from this material exist. The described parameter can be external and internal. The 1st varies from 16 to 110 mm, while the inner one varies from 16.2 to 90 mm. If we consider the dimensions of the pipes in more detail, then the wall thickness can vary from 1.9 to 10 mm.

As for the area of use, large-diameter pipes are used for laying water supply, sewerage andheating to residential neighborhoods and houses, sports complexes, public buildings, as well as hotels. Such products are used for industrial needs. For example, if the diameter of polypropylene is 500 mm, such a pipe is used to supply cold drinking water to metropolitan areas from storage pools. Polypropylene pipes are not used to transfer coolant due to the high thermal load, which leads to softening of polymer lines.

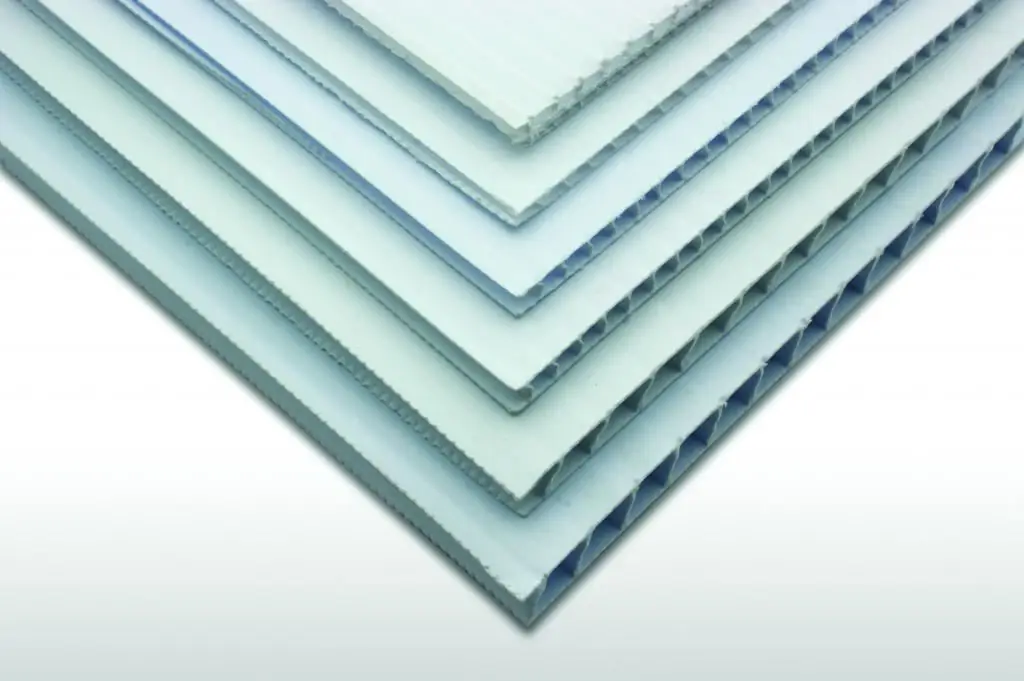

Description of PP sheets. Areas of use

Polypropylene sheets are used for the transportation and storage of alkalis and acids, as well as chemicals due to the fact that the material is well resistant to chemical, temperature and other influences. It is stable and can be used in the food industry to store various liquids and food. Such sheets can be monolithic or composite. The former are also called homogeneous, and the latter are lightweight. They have internal foam and external solid decorative layers.

Among the main properties should be highlighted:

- rather low density;

- very high strength;

- high frost resistance;

- good chemical resistance;

- safety for human and animal he alth;

- good machinability;

- excellent dielectric performance.

Laying the heating system and soldering pipes

DIY frompolypropylene can lay the heating system in your house or apartment. The material today is affordable and fairly light. Before starting work, it is necessary to designate the joints and figure out how to install pipes. For soldering, the product must be cut to size. The joints must be even and have a right angle. Sections are degreased, chips are removed from the surface after cutting.

The pipe is installed in the centralizer. This will achieve the geometric accuracy of the connection. Fittings are then put on the docking points. Polypropylene soldering is carried out using an inverter. The device heats up, after which you can begin to manipulate.

You can also use electric welding couplings. In this case, the installation is carried out in them. If it is necessary to connect polypropylene products to a metal pipe system, flanges should be used. On the one hand, they have a thread for tapping into metal pipes. On the other hand, the product has a smooth shutter for mounting on plastic.

If you plan to use polypropylene for heating, it is important to determine the welding time of the joints, which will depend on the diameter of the pipes. All elements of the system are preliminarily brought into the room. They need to be warmed up to room temperature. Using the calculated data, you need to put the cutting places on the surface of the products with a marker. The work is best done with special scissors. Sections are wiped with an alcohol solution. Use a dry cloth to remove any remaining dirt. Next comes the turn of the nozzle for the soldering iron. You must select the appropriate diameter. The nozzle is degreased and installed horizontally. It is heated to 265 ˚С.

The pipe and fitting are placed in the heater opening. The elements to be connected take some time to heat up. After they are removed from the product and the pipe is inserted into the fitting. At this stage, it is important to withstand the required time. The parts to be joined should not be touched until they are completely cool.

In closing

Polypropylene is a chemically resistant material. Only certain acids and oleum can have some effect on it. The destruction of polypropylene occurs only with prolonged contact with reagents such as sulfuric acid and hydrogen peroxide. Swelling of the material may occur in organic solvents. Upon contact with aromatic hydrocarbons and a temperature of 100 ˚С and above, dissolution occurs.

Recommended:

Life and he alth insurance. Voluntary life and he alth insurance. Compulsory life and he alth insurance

To insure the life and he alth of citizens of the Russian Federation, the state allocates multi-billion sums. But far from all of this money is being used for its intended purpose. This is due to the fact that people are not aware of their rights in financial, pension and insurance matters

Clothing industry as a branch of light industry. Technologies, equipment and raw materials for the clothing industry

The article is devoted to the clothing industry. The technologies used in this industry, equipment, raw materials, etc. are considered

Dairy industry in Russia. Dairy industry enterprises: development and problems. Dairy and meat industry

In the economy of any state, the role of the food industry is huge. Currently, there are about 25 thousand enterprises in this industry in our country. The share of the food industry in the volume of Russian production is more than 10%. The dairy industry is one of its branches

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics

Thermite welding: technology. The practice of thermite welding in everyday life and in the electrical industry

The article is devoted to thermite welding technology. The features of this method, the equipment used, the nuances of use, etc. are considered