2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

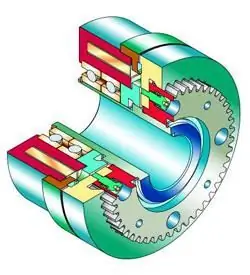

In any mechanism that uses shafts to actuate, there is always a connecting part and is called a gear coupling.

If there are two shafts that need to be connected along the same axis or at an angle to each other, then the best way to transfer loads and forces is a semi-rigid connection using a gear coupling. A single gear coupling is installed on the condition that only angular displacement is allowed between the shafts. If there is a need to compensate also for radial or axial displacement, then two single couplings are installed. The gear coupling has increased reliability and good bearing capacity, since it is equipped with a large number of teeth. Such couplings work well in mechanisms with a high rotational speed (cranes, conveyor equipment).

Couplings successfully compensate for radial, angular and axial displacements of the shafts, due to the presence of lateral clearances in the engagement and on the teeth of the sphere bushings. All parts that make up the coupling are made of steel: for a shaft with a diameter of up to 140 mm - forged, and for large diameters - cast. To increase the wear resistance of the teeth, they are heat treated, and inthe clutch is injected with viscous oil.

In principle, the gear clutch has much in common with the cardan transmission, although it provides compensation for smaller angular displacements, but it has more torque per unit volume.

Gear Coupling Features

The gear coupling consists of two coupling halves connected by bolts and two bushings inserted into the drum cages. Between themselves, they are engaged with teeth of a spherical shape. Such couplings are standardized according to GOST 5006-55 for shafts with diameters from 40 to 560 mm. There are also other standards for gear couplings that are used for unification in all CIS countries, depending on the torque, for example, GOST R 50895-96 (Russia), DSTU 2742-94 (Ukraine).

The wide range of applications and the various requirements that apply to couplings have led to the fact that today couplings are divided into several classification groups according to their design features.

Thus, according to the principle of operation, the clutches are divided into permanent, coupling and self-controlled, and according to the nature of work - into rigid and elastic.

According to the execution, there are couplings with a split cage (gear coupling GOST 5006-55-MZ), with a one-piece cage and with an intermediate shaft (GOST 5006-55 - MZP).

For the short ends of the shaft, bushings are made for the coupling according to GOST 12080 with cylindrical holes, and according to GOST 12081 - with conical holes.

Also gear couplings can be manufactured in accordance with customer specifications. If the customer needs an exclusive gear coupling, the drawing must accurately show all the necessaryparameters.

When mounting the couplings, some features should be observed, in particular, mounting on the shaft should be carried out with little heat.

Recently, gear couplings made of polymer compounds (kapron, caprolon) have been actively used. Increased elasticity and the ability to more evenly distribute the load on the teeth, puts them on a par with metal ones. In addition, polymer couplings are more electrically insulating and cost effective.

Recommended:

Autoclaved aerated concrete: production, scope, material features

This type of porous concrete has been on the list of first building materials for a long time. Therefore, many factories and companies are engaged in its manufacture. With the development of technology, you can find autoclaved aerated concrete in various shapes, sizes and colors

Carbon is Carbon: description, scope, features and reviews

Carbon is a modern material actively used in a wide variety of industries and other areas of human life. We will talk about this most interesting product in as much detail as possible in the article

Heat-resistant glass: manufacturing features and scope

Glass is one of the most ancient and versatile materials. Glass products are all around us, but usually we do not think too much about its characteristics. They can vary greatly depending on the purpose of using the future product. One of the most common types is heat-resistant glass. Let's find out how it differs from the usual one and where it is applied

Flange plugs: scope and design features

Flange plugs are structural elements designed mainly to cover all kinds of end openings of pipeline systems and highways

What is the difference between a lawyer and a lawyer, what is the difference? How a lawyer differs from a lawyer - main duties and scope

People often ask such questions: "What is the difference between a lawyer and a lawyer?", "What is the difference between their duties?" When life circumstances arise, when it is necessary to turn to representatives of these professions, you have to figure out who is needed in a particular situation