2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:33

Flange plugs are structural elements designed mainly for closing all kinds of end openings of pipeline systems and pipelines. They are also often used to seal those branches in which there is no longer any need. Flange plugs serve as the main structural element to ensure the safety and reliability of operation of pipelines of any type.

At the moment, there are many varieties and modifications of this end piece, each of which differs in shape, material, method of fastening and design features. Flange plugs, as a rule, are installed on the desired outlet of the pipeline using threaded connections. The main feature of such products is that there are no holes directly in the central part of their case.

Flanges for pipelines in their structural structure are not much different from similar products used in other industrial and economic areas. Plugs of this type are mainly produced by hotstamping or cutting from solid sheets of steel alloys. This technological approach causes the absence of any joints or moving parts, which only adds to the product reliability, durability and safety.

Flange plugs are most often used on pipelines of the chemical, gas, oil industries, as well as on other lines of increased environmental hazard. Such parts, manufactured in compliance with all technological standards and correctly installed, are designed for pressure from 6 to 160 kg/cm2. But in practice, they are able to withstand even more, as manufacturers put in them a certain reserve and margin of safety.

As for the temperature range and climatic conditions, this type of steel plug demonstrates excellent functionality and durability in the range from minus seventy to plus six hundred degrees Celsius, as well as in conditions of high humidity or, conversely, great dryness of the air. Depending on the design features and the type of sealing joint, four types of these products are distinguished: with a ledge, a hollow, studded and for oval pipelines.

Such plugs have an extremely high resistance to the destructive effects of all kinds of chemically aggressive environments. That is why they are intended primarily for use in the toxic extreme conditions of the chemical industry. They can be used for short-term or permanent preservation.flows in the end zones of pipelines and be sure of the safety of the line, for some reason decommissioned. It is also quite expedient to use these products for the production of all kinds of containers and reservoirs of industrial scale and purpose.

Recommended:

Carbon is Carbon: description, scope, features and reviews

Carbon is a modern material actively used in a wide variety of industries and other areas of human life. We will talk about this most interesting product in as much detail as possible in the article

What are flange connections? Types of flange connections. Flanged connections in industry

Flanged connections are often used in industry. They must ensure the tightness and strength of the assembled structures. The role of a high-quality connection is important, because a weak bond can lead to large losses and threaten the danger to the operating personnel

Heat-resistant glass: manufacturing features and scope

Glass is one of the most ancient and versatile materials. Glass products are all around us, but usually we do not think too much about its characteristics. They can vary greatly depending on the purpose of using the future product. One of the most common types is heat-resistant glass. Let's find out how it differs from the usual one and where it is applied

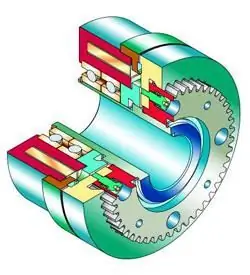

Gear coupling: scope and features

Most mechanisms, turbines, conveyors would not be able to work if they did not use such a small but very necessary part as a gear coupling. Let us consider in more detail the scope and features of gear couplings

Utes machine gun: design and scope

The "Utes" machine gun was replaced at the combat post by the DShKM. It was adopted in the mid-70s. This is one of the most powerful types of large-caliber small arms