2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Aluminum oxynitride (or AlON) is a ceramic composed of aluminum, oxygen and nitrogen. The material is optically transparent (> 80%) in the ultraviolet, visible and half-wave ranges of the electromagnetic spectrum. It is manufactured abroad by Surmet Corporation under the ALON brand. Recently, Russian scientists have developed a technology for producing transparent aluminum, which is somewhat different from imported analogues.

Description

The development of a unique alloy has opened up new prospects in the defense industry, science and construction. According to official figures, ALON:

- 4 times stronger than tempered quartz glass;

- 85% harder than sapphire;

- nearly 15% more durable than magnesium aluminate spinel.

By the way, the mineral spinel is a direct competitor of transparent aluminum andinferior to oxynitride in a number of parameters.

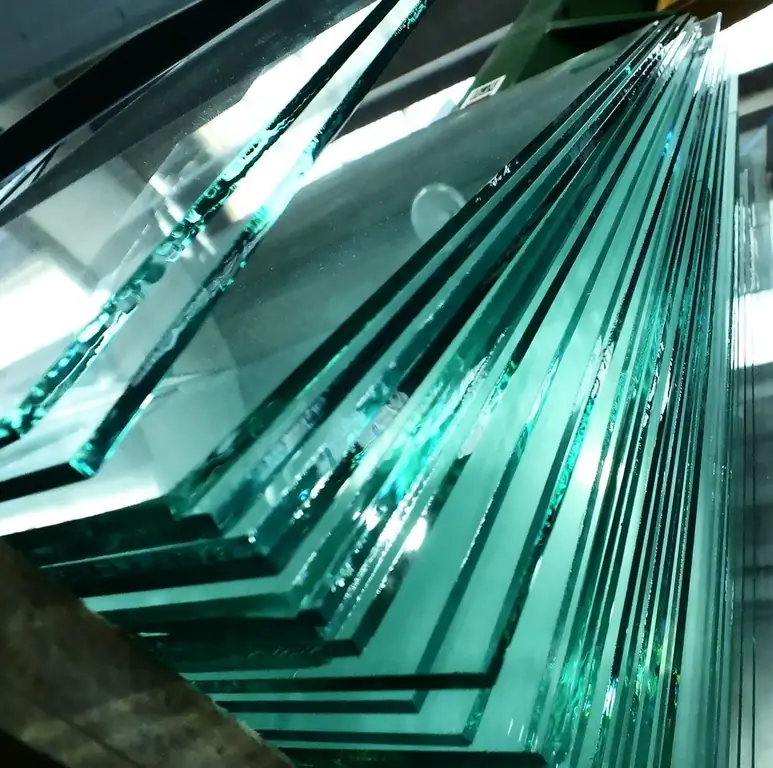

ALON is the hardest commercially available polycrystalline clear ceramic. The combination of optical and mechanical properties makes this material a leading candidate for lightweight, high-performance armored products such as bulletproof and explosion-proof glass, elements for infrared optical systems. Aluminum oxynitride is also used to produce transparent impact-resistant windows, portholes, plates, domes, rods, tubes and other products using traditional ceramic powder processing technologies.

Mechanical properties

Aluminum oxynitride has outstanding performance:

- Modulus of elasticity: 334 GPa.

- Shear modulus: 135 GPa.

- Poisson's Ratio: 0, 24.

- Knoop hardness: 1800kg/mm2 at 0.2kg load.

- Fracture resistance: 2 MPa m1/2.

- Bending strength: 0.38-0.7 GPa.

- Compressive strength: 2.68 GPa.

Optical and thermal properties

When testing transparent aluminum, the following indicators were obtained:

- Heat capacity: 0.781 J/K.

- Thermal conductivity: 12.3 W/(m K).

- Coefficient of thermal expansion: 4.7×10-6/°С.

- Transparency range: 200-5000 nm.

ALON is also resistant to radiation and damage from various acids, alkalis and water.

Receive

Transparent aluminum oxynitride is made by powder sintering like other ceramic materials. While the US Navy is busy developing a new bulletproof material called artificial spinel, Surmet Corporation is already releasing its own version of "bulletproof glass" called ALON.

Developed in Raytheon laboratories, a special powder is molded and held at very high temperatures. The composition of the mixture may vary slightly: the aluminum content is approximately 30% to 36%, which slightly affects the performance (the difference is only 1-2%).

The heating process causes the powder to rapidly liquefy and cool, leaving the molecules loosely arranged as if they were still in liquid form. It is this crystal structure that gives transparent aluminum a level of strength and scratch resistance comparable to sapphire.

Manufactured products are subjected to heat treatment (compaction) at elevated temperatures, followed by grinding and polishing until transparent. The material can withstand temperatures up to 2100 °C in inert gases. Grinding and polishing significantly improve impact resistance and other mechanical properties.

Domestic equivalent

Russian scientists created transparent aluminum in 2017. According to specialists from NRNU MEPhI, the production technology wasgreatly improved. In the manufacture of compacts, the technique of spark-plasma sintering is used.

Unlike foreign colleagues, domestic developers do not pass an electric discharge through an external heating element, but directly through a mold. Scientists say that domestic transparent armor is comparable in strength to cubic zirconia, but at the same time has high impact strength.

Comparison of aluminum armor with bulletproof glass

Traditional bulletproof glass consists of multiple layers of polycarbonate sandwiched between two layers of glass. Similarly, transparent aluminum armor consists of three layers:

- outer layer - aluminum oxynitride;

- middle layer - glass;

- back layer - polymer backing.

But the similarity ends there. Aluminum armor can stop the same bullets from small caliber weapons as traditional bulletproof glass, but it will still be transparent even when fired without the characteristic cracks. In addition, the strength of ALON is much higher.

Aluminum oxynitride armor can be made into almost any shape. She is not afraid of sand, gravel or dust. The resistance to abrasive materials is very high. Despite the excellent properties of transparent aluminum, this material is not widely used. The biggest deterrent is cost (3-5 times more expensive than traditional bulletproof glass). ALON is currently used mainly for lenses of observation instruments and sensors.missiles.

Recommended:

How to make glass? Glass production technology. glass products

Glass is familiar to everyone. But the process of making it is extremely exciting. Each stage is important and affects the quality of the final product. The basis is sand, soda, lime. The process is almost entirely automated. Surprisingly, glass can even be made at home

Glass sandblasting: glass processing description, equipment, application, photo

Among the numerous variations of interior decoration, sandblasting of a glass or mirror surface occupies a special place. This technology involves exposing the canvas to sand or other abrasive with a jet of compressed air released under high pressure. As a result, the surface changes and becomes matte, rough, velvety or painted with patterns. In the article we will consider what is sandblasting glass

Corrosion of aluminum and its alloys. Methods for combating and protecting aluminum from corrosion

Aluminium, unlike iron and steel, is quite resistant to corrosion. This metal is protected from rust by a dense oxide film formed on its surface. However, in the case of destruction of the latter, the chemical activity of aluminum greatly increases

Deciphering the armored personnel carrier - "armored" or is it still a "transporter"?

Many are interested in the question of how to translate the APC spelling. The confusion often arises from the fact that only two words are indicated by three capital letters. Deciphering the abbreviation BTR looks like "armored transporter"

Grinding car glass. How to grind glass

The article is devoted to glass grinding. The grinding procedure, its tasks, technique, materials, etc. are considered