2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

Elevator buckets are widely used in agriculture, food and mining industries for transportation of powdered, bulk and lumpy materials. Structurally, they differ in material, shape and geometry, as well as in manufacturing technology.

Destination

Elevator buckets are designed for transportation of bulk materials and are used in the following industries:

- agriculture (grain in elevators, animal feed on livestock farms);

- fuel industry (wood pellets in the manufacture of pallets);

- food industry (grain and flour - at flour mills, m alt - at breweries, meal - at oil extraction enterprises, cereals - at cereal factories, tea - at tea-packing factories);

- construction and mining industry (sand, coal, cement, peat).

These items are secured to belt bucket elevators with anti-rotation knurled bolts or drive chain (heavy duty).

Views

According to the manufacturing method, elevator buckets are classified as follows:

- Seamless. Obtained by stamping (drawing) from a single metal sheet. Mounting holes are punched on the press.

- Casting. This method applies to plastic and aluminum buckets.

- Prefabricated welded. The central part of the structure is made by stamping or rolling. Then the side walls are welded.

The main material for the manufacture of this structural element is used:

- common grade carbon steel (Multi Purpose Buckets);

- stainless steel (for food);

- galvanized steel;

- polymeric materials (polyethylene, synthetic polyamides, polyurethane and other compositions).

When choosing them, the following parameters are also taken into account:

- bucket volume;

- its depth;

- shape;

- bowl out.

Polymeric elevator buckets

Polymer buckets have a number of advantages over metal ones:

- low cost and easy to manufacture;

- corrosion resistance, chemical inertness;

- quiet operation;

- electrical and intrinsic safety;

- no damage to bulk solids due to soft edges;

- light weight, reduce the load on the elevator belt, reduce energy consumption;

- small adhesion of loose materials to the walls due to their smoothness.

At the same time, suchbuckets have sufficient rigidity and retain their shape well during operation. They are used to work with food products under temperature conditions from -40 to +60 ˚С.

Recommended:

Elevator job description. Rules for the safe operation of elevators

The lifter in the course of his professional activity performs one main task - to ensure technical safety during the operation of elevators. Today, qualified specialists are in demand at all enterprises where there are elevators. The job description of an elevator operator is a document that clearly limits the duties, rights and responsibilities of a person holding this position

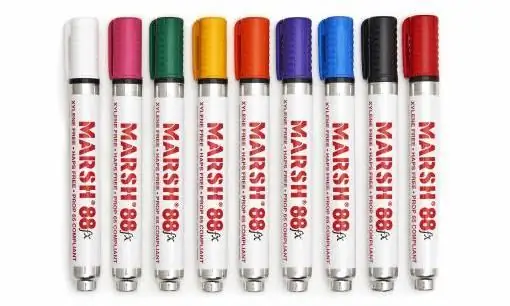

Industrial marker: description, composition, rules, application and purpose

Industrial marker - a writing tool for applying information on a variety of surfaces. In this case, the surface can be wood, glass, stone, metal, leather, painted materials and even rust. The requirements for such a marker are very specific

Elevators are Water jet elevator. Heating elevator

An elevator is a device that is necessary to lower the temperature of the coolant entering residential buildings. This device reduces the temperature of the water by partially mixing with the cold liquid from the return pipe. Currently, water jet elevators are not available at every CHP. Let's take a closer look at what this device is, how it works and whether it makes sense to install it. We will also consider other types of elevators

Where is the bucket elevator used?

A bucket belt bucket elevator is a vertical conveyor that transports bulk materials vertically upwards to a certain height. This unit is used in the scheme of various technical processes both indoors and outdoors

Modern durable and high quality material G10: description, properties and application

People have been using knives as household tools for a very long time. With the passage of time and the improvement of technology, more and more new substances were used to create this tool. To date, the G10 material has become a new word in the creation of these things