2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

In modern metallurgy, a huge number of steels are used. Their characteristics, as well as the variety of nomenclature, are truly immense. However, in different industries there are still the most common and popular grades of this material, which are used for rather specific needs.

For example, the characteristics of steel 65x13 suggest its use as a material for the production of excellent knives. Why are we so categorical? You can read this article to find out.

Steel. Stainless steel specifications

Simplistically, steel is an alloy of iron and carbon. A lot of carbon - cast iron, little - tin. The "middle" state can be called steel. Its various types are determined not only and not so much by the proportions of iron and carbon, but by alloying with various additives and impurities that give the steel different properties.

The properties of alloys depend both on the chemical components that make up their composition and on the technological conditions of production. Sometimes steel is made composite, when it consists of several layers of different grades, or Damascus, when there are several layers in the material.hundreds of layers (one brand). The material may contain the following additional components:

- If the total amount of the additive does not exceed 1.5%, then we are talking about modifiers that help improve the mechanical, physical and chemical properties of this category of materials. More than 1.5% - alloying additives that give steel resistance to corrosion.

- Carbon. This element, as we said, is present in all types of alloys, giving them rigidity and strength. Too much of it turns steel into cast iron.

Brief characteristics of knife steels

In general, in addition to iron, they always contain carbon and chromium. Note that carbon in steel for knives cannot be less than 0.5%. Experts believe that the optimal content is 1%. Steels that already contain 1.25% carbon become very hard, but extremely brittle. If there is a need to create such a material, then vanadium and molybdenum are included in its composition.

However, there are also damask steels, which generally contain 1.5-2% carbon (up to 4% in some cases). Their strength and flexibility is due to the special technology of forging and hardening.

Main alloying components

Chrome. This additive is necessary to give the material resistance to wear, as well as to enable it to be hardened. Of course, it is chromium that makes steel truly stainless. But this category includes only that kind of material, which contains at least 13%this supplement. In fairness, it should be noted that almost any steel undergoes corrosion: it all depends only on the operating conditions and the presence / absence of care for the product.

Manganese. It gives the material graininess and a special texture, which contributes to a sharp increase in the strength characteristics of the blade, as well as its rigidity. There is the concept of "killed steel", which is applied to those alloys that have been improved by adding manganese. Note that the characteristics of steel 65x13 (rigidity, relative hardness) are due to the presence of this particular type of additive.

Molybdenum. An extremely important element, as it prevents the blade from breaking and brittleness, the material for which it contains too much carbon. It is important to note that air-hardened steels contain at least 1% molybdenum in their composition, due to which this type of hardening becomes possible at all. Some believe that it is this additive that gives the alloy toughness and hardness.

Nickel. Firstly, it serves to impart viscosity to the alloy. Secondly, it is also an alloying additive that protects steel from corrosion. In general, the combination of these qualities is very similar to molybdenum.

Silicon. Oddly enough, but it is used to give the blade of a knife elasticity. In some respects, its properties are similar to those of manganese.

Tungsten. Extremely popular with high-end knife makers, as it is used to drastically increase the wear resistance of the product. It also gives steel a special hardness andresistant to even extremely high temperatures. When tungsten is combined with molybdenum or chromium, the material becomes "fast cutting". A small digression: tungsten, nickel and molybdenum are key additives not only in the manufacture of knife steel, but also in the production of tank armor. Without these elements, it is impossible to get really high quality.

Vanadium. Like many of the above additives, it gives steel hardness and strength. It is extremely important in the manufacture of fine-grained alloys. It is used not only for the manufacture of knife steels, but also for the development of the same tank armor.

Some believe that nitrogen should also be classified as an additive, but this point of view is incorrect: the fact is that it enters the alloy from the air, and it does not have any effect on its characteristics in the least.

Ballast

Nitrogen, like some other elements, is always present in steel. Such elements are called ballast. However, occasionally they are still purposefully added to the composition of the alloy, since some of them are able to improve its performance. Some (sulfur and phosphorus, for example) should not be present at all in the alloy: their content is limited by numerous standards.

Why did we paint all this? The thing is that you should be clear about the general characteristics of knife steels, as many of them are very specific, not much like, for example, the alloys used to make boilers or something like that. So, in some cases, the steel grade is 65x13, propertieswhich will be described in detail below, due to the high content of phosphorus and sulfur becomes completely unsuitable for the production of knives.

What is the best steel for knife production?

So what brand is best for making knives? The question is very provocative, since there are thousands of answers to it and there is no consensus (and there cannot be). Much depends on the method of hardening and finishing. Even excellent steel can be turned into a piece of slag by hardening it incorrectly. Experts believe that the most suitable for most conditions are knives made according to the composite scheme: with hard-alloy "cheeks" and a mild steel core.

However, this is all lyrics, since we are interested in the brand of the material. Today we will consider steel 65x13, since in 97% of cases it is used by domestic knife manufacturers.

General information

This is the most common and popular domestic steel suitable for the production of knives. The letter "X" in the middle of the name indicates that the material contains chromium, which makes it resistant to corrosion. Most often, this steel is used in the manufacture of medical instruments and equipment for the food industry. Knives from it also turn out to be quite decent quality, although some claim that they dull rather quickly.

What is special about steel grade 65x13? It is believed that knives made from it really never rust (if you do not take into account the aggressive chemicalenvironment). Not surprisingly, almost the entire range of domestic knives is made from this material. It should be noted that the characteristics of steel 65x13 are very close to the American brand 425mod. When quenched well, both materials show excellent results.

Hardness

Strange as it may seem, even domestic knife lovers sometimes differ diametrically about the hardness of this steel. Someone considers it "soft", while others claim its "high hardness" or "medium" characteristics. So how are things in reality? First, let's talk about general concepts.

All over the world, Rockwell units are used to interpret hardness, for which there is a generally accepted designation HRc. It should be noted that the most optimal for knives is an indicator of 40 to 60 units, and steel with a hardness of 52 to 58 units is best suited for a working tool. If the manufacturer claims 60 or more Hrc, you should be on your guard: this is either an extra-class product, or a banal scam of a potential buyer.

So what are the characteristics of steel 65x13? Experts say that with proper hardening, its hardness is 56-59 HRC. There is no smell of softness here. So where did the tales come from that this steel is soft and wears out quickly? It's simple.

The point here is in the banal culture of production. It often happens that unscrupulous manufacturers generally do not pay much attention to hardening and annealing. In addition, it also happens that steel 65x13 in generalis not used, but the brand 20x13 acts instead. Its quenching hardness is only 45-48 units. This is how legends about the “softness” of steel appear, the real characteristic of which is 56-59 HRC Rockwell units!

In a word, let's close the topic. Once and for all - steel 65x13 (reviews of knives from which we will consider below) is quite cheap and common, but at the same time hard (though not very high quality). Important! It is worth considering that it is not worth heating this material to a hardness of more than 57 Roxwell units at home, since such a blade can still begin to crumble under loads.

Other benefits

The working edge of such blades is not prone to chipping even with intensive use, and the knife will hold both strong bends and blows well. Due to the absence of high-quality alloying additives in the composition of the steel, the blade will dull rather quickly, but it can also be sharpened quickly. Of course, due to the same lack of additives, the tribological properties of this grade of steel are not very good, but they are much better than those of really soft grades.

But experienced tourists and just lovers of knives talk about another advantage of this alloy and knives made from it. Since there are practically no alloying additives in the composition of this material that would provide increased strength (more on this below), the geometric configuration of the knife can be absolutely any. This 65x13 (reviews say the same) compares favorably with "professional" steel grades, with which this approach will not work.

Chemical composition of steel

Remember what we talked about at the very beginning of the article? We discussed the various additives that can be present in knife material. What does steel 65x13 have? Reviews indicate that this material does not belong to the elite category, and there is a simple explanation for this. To make it easier to understand, just take a look at the table below.

| Carbon | Chrome | Manganese | Molybdenum | Nickel | Silicon | Sulfur | Phosphorus | Selenium |

| 0, 65 | 13 | 1 | 0, 75 | 1 | 0, 03 | 0, 04 | 0, 75 |

That's what makes 65x13 steel different. Characteristics (reviews directly depend on them) indicate that of all the alloying additives in this case, only chromium is available in sufficient quantities. This provides excellent corrosion resistance. The relatively strong abrasion and the need for frequent sharpening is due to the lack of specialized additives.

Important! The table shows that in the brand 65x13 (reviews of which we are considering) there is little sulfur and phosphorus. But! Store shelves are full of Chinese crafts that are made (as if) from this steel, which already contains more than 0.06% sulfur and phosphorus. This is very bad, since the hardness of 65x13 further enhances the negativemanifestations from these garbage impurities.

First of all, the Chinese already often overheat the knife. Accordingly, this leads to chipping of the blade. Secondly, such a high content of these harmful impurities leads to a sharp increase in the risk of a cold fracture of the knife even under moderate loads. By the way, the occurrence of the vast majority of negative reviews depends on this nuance.

In a word, we once again explain some of the attacks that 65x13 steel is subjected to (characteristics). A knife made of Chinese alloy, even if the name of this brand is etched on it, should not be taken seriously! Unfortunately, many inexperienced tourists, fishermen and hunters completely forget about the manufacturer, preferring to blame the broken blade on the steel grade itself, although it has nothing to do with it in this case.

Knife Reviews

As you may have noticed, there are plenty of opinions about knives made from this alloy. And there are a lot of both positive and purely negative reviews. We have examined the reasons for both in some detail above, and therefore we will not dwell on the general points. Let's talk about individual knives made of this steel, which are especially common among domestic fishermen, mushroom pickers and hunters.

Bear

General characteristics are as follows:

- Total length is 23.5 centimeters.

- The length of the blade itself is 11.5 centimeters.

- Blade width is 28mm.

- Blade thickness - 2.8 mm.

The knife is equipped with a relatively thick handle (3.3 cm), which fits comfortably in the hand and does not slip, even if the person sweats. Other specifications vary from manufacturer to manufacturer. So, in some cases, the blade has an etching in the form of a bear, while other manufacturers do not practice this.

As a rule, there is no guard on the blade, but many manufacturers additionally stipulate the possibility of its installation (even from precious metals). In all cases, the handle is made of walnut, but the way it is attached is different (ordinary riveting is often found).

However, we are not interested in this. Why is the 65x13 “Bear” knife interesting for customers, how do people who have already made a purchase speak about it? Firstly, they like the price: from 1350 rubles in the "basic configuration", without frills and precious metals in the finish. For this amount, judging by the reviews, you get a wonderful knife for outdoor activities, which in the field can be sharpened almost “about a pebble”.

Since the length of the blade is within the police regulations, the "Bear" is not a melee weapon. Many people like the simple, without sharp and sinuous lines, the geometry of the cutting part. The knife is easy to care for. When buying, it is important to pay attention to whether a particular manufacturer has stinted on a normal varnish for the handle. Judging by the reviews, they often save on this. In addition, we strongly recommend choosing a model with a guard: some manufacturers have a handle that is not very well shaped, and therefore a hand smeared with blood or grease can slip onto the cutting edge.

For the sameFor this reason, we recommend buying a "Bear" with a birch bark handle, as the hand practically does not slip on it.

Tiger

Another member of the knife "zoo". Unlike the previous variety, it is officially cutting. As in the previous case, a pattern can be applied to the blade. The possible names of the tree for the handle are much wider: from the same walnut to wenge and other exquisite species. The Tiger knife itself 65x13 has the following characteristics:

- Total length is 27 centimeters.

- Blade - 14.5 centimeters.

- Notice the width of the blade, which is 42 mm.

- Comes with a leather sheath.

As you can see, the dimensions of this knife are much larger than those of the Bear. That is why it is especially popular with fishermen and hunters who prefer long forays into the forest: judging by the reviews, people are impressed by the long blade, which is convenient for butchering prey. Like all other knives made of steel 65x13, it dulls relatively quickly with intensive use, but sharpens just as quickly. At the same time, as in the previous quality, it is often possible to get by with the simplest devices.

In some cases, in order to attract "aesthetes", manufacturers make quite exotic things with this knife. For example, you can meet the "Tiger" coated with titanium and tungsten sputtering, and almost all manufacturers offer gilded blades. But the practical value of such knives is close tozero.

Experienced users say that spraying (subject to actual use) will wear out and chip off anyway. As a result, the knife will look like a panda: the alternation of whole and peeled sections of the blade does not look very aesthetically pleasing. In addition, the price of such knives is appropriate: if the usual "Tiger" costs around 1800 rubles, then the "refined" options, it happens, are already sold for 10 thousand, or even more.

By the way, about the manufacturers. Who especially “succeeded” in steel 65x13? Kizlyar is a particularly well-established manufacturer. So to speak, "number of times" according to buyers. Experienced knife lovers claim that it is the Kizlyarovsk "Tigers" and "Bears" that are distinguished by the most optimal ratio of price and quality.

What other 65x13 steel knives are there? Reviews of which models are the most impressive?

Hunter

This model, as the name implies, is aimed at hunting enthusiasts. The knife has a straight, somewhat rough shape. Excellent for skinning and butchering medium-sized game. The main features are as follows:

- Total length is 25.8 centimeters.

- The length of the blade is 13.6 centimeters.

- The width of the knife varies, depending on the manufacturer, from 4.2 to 4.6 centimeters.

- Blade thickness - 3.0mm.

Like other varieties, it can be produced in decorated versions, when precious metals and precious woods are used for decoration. However,an ordinary knife "Hunter" 65x13 is no different from the "elite" variety (except for the price, of course). And the usual variety costs about one and a half thousand rubles.

What attracts potential buyers in this knife? First, the reviews indicate an attractive appearance. Secondly, buyers are impressed by the geometry of the blade, which is ideal for hunting purposes. Is there any other 65x13 knife worthy of a professional's attention? There is, of course.

Vityaz

The most representative of all knives reviewed. Here are its main features:

- Total length - 31.5 centimeters.

- The length of the blade is 19.5 centimeters.

- Blade width - 32 mm.

- Knife thickness - 4.5 mm.

The material, as in all other cases, is steel 65x13. Characteristics: the knife "Vityaz", as we have already noticed, has an elegant, sophisticated appearance. The logo of a specific manufacturer is etched in gold on a long blade tapering to the base. In general, in appearance, the knife is very similar to a dagger or even a Roman gladius.

Customers note that it should not be used in the field, as the beautiful appearance may well suffer from harsh environmental conditions. In addition, the cost of about 10 thousand rubles somehow does not contribute to the use of the Vityaz for cutting fish or meat, not to mention the “quiet hunt” for mushrooms. But this is a great gift for connoisseurs.

This is how knife steel is different65x13. As you can see, at a relatively low price, it has very decent characteristics, which makes it possible to make excellent working blades from this material that do not rust, do not crumble, and can be sharpened with almost any bar. This ensures their wide distribution among domestic fishermen and hunters.

Recommended:

Knives made of steel EI-107: characteristics of Zlatoust products

You can walk around shop windows for months, looking at the products of Zlatoust gunsmiths. Many people like to admire the famous stainless steel knives. At such moments, you suddenly begin to think about the quality of weapon metal. And to a greater extent about the characteristics of steel EI-107, used in the manufacture of a large number of knives, daggers and blades in Zlatoust. The history of the emergence of the Zlatoust brand and the advantage of purchasing products from this brand is interesting

What is milk made of? How is milk powder made?

Surely everyone is concerned about the question of what milk is made of. In this article we will try to find answers to it and learn a lot about this product familiar from childhood

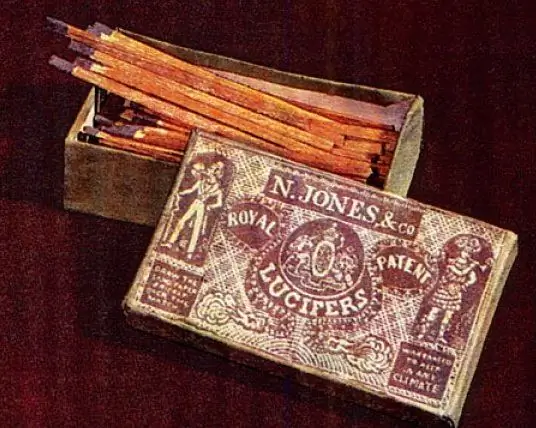

How were matches made before and how are they made today? Swedish matches

The article is devoted to the history of the creation of matches - from their very first prototypes to modern ones. It also tells about the famous Swedish matches, the evolution of the chemical components of the match head and stickers for the box

Description of steel 65G. Material for the production of knives

The variety of steel in our time is quite large. Each brand differs from another in a number of physical or chemical, or operational properties. Because of this, it is not always possible to use the same steel grade for the manufacture of various kinds of products. Steel 65G has proven itself from the best side in the manufacture of knives

440 steel - stainless steel. Steel 440: characteristics

Many people know 440 steel. It has established itself as a reliable, anti-corrosion, time-tested hard material, which is most often used for the manufacture of knives for various purposes. What is the secret of this alloy? What are its chemical, physical characteristics and applications?