2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:25

Quartz sand is a material that is of natural origin and has characteristics such as chemical inertness, fracture resistance, strength, and sorption capacity. Most often it is used in the filtration of oil products and water, for the production of finishing and building materials, as well as in the creation of swimming pools. Now about everything in more detail.

Filtering capacity

Quartz sand for filters is used much more often than any other natural material. The fact is that its porosity is much greater compared to ordinary crushed sand. This, in turn, provides it with the highest dirt holding capacity and sorption capacity, due to which even elements such as manganese and dissolved iron are removed from the water. For the same reason, quartz sand for a pool, artificial pond or lake, or rather, for their filtration system, is almost always used. The recommended fractions in these cases range from 0.4 to 6.0 millimeters.

Construction use

Wide application of quartz sand has inconstruction industry, in particular, when creating polyurethane and epoxy floors. In this case, it should have a coarse-grained fraction. The use of this material in the manufacture of plasters and building mixtures is due to its high chemical resistance, mechanical resistance to crushing and abrasion, as well as color stability. Fine fractions are well suited for sandblasting when processing glass, concrete and metal. The material is also used in the production of artificial stone.

Other areas

The use of quartz sand is not limited to all of the above. It is often used in the construction of greenhouse drainage systems, drilling of water wells, as a feed for poultry, and as a filler for electrical insulators and waterproofing material. Recently, this type of sand can be found in aquarium and landscape design.

Production

Being a fairly common natural material, quartz sand does not directly enter filters, building materials or other applications directly from a quarry. This can be primarily explained by the nuance that in order to solve certain problems it is necessary to select a suitable fraction. In addition, sand usually contains a large number of various impurities, and therefore the material needs to be pre-treated, which is a rather complicated process.

Application Features

The appearance of ready-to-use quartz sand is preceded by several operations at once, including cleaning of raw materials from impurities, drying, fractionation, dosage and packaging. At the same time, the importance of the fraction for this material should never be underestimated, because in certain industries (for example, in the production of glass) it plays a key role. Another important criterion that characterizes quartz sand is the absence of a chemical reaction in it. This applies, first of all, to construction, because after hardening of cement mortars or concrete, undesirable consequences may occur.

Recommended:

Loose material (sand, crushed stone): production and sale

Sand and crushed stone are used as bases for various buildings and landscaping, as well as aggregates for concrete

Polyols are polyhydric alcohols (polyalcohols): properties, production and applications

Polyols - safe or not? What are polyalcohols, why are they included in the composition of chocolate, chewing gum, foam rubber and antifreeze. The most famous polyols are sweeteners. Production of polyhydric alcohols in Russia and abroad

Raw material for industry - white quartz sand

What miracles are not prepared on Earth for man! Here, for example, is an amazing sight - white sand. From afar, you won’t immediately understand: is it snowdrifts in the middle of summer, or mountains of granulated sugar, or maybe table s alt or another chemical?

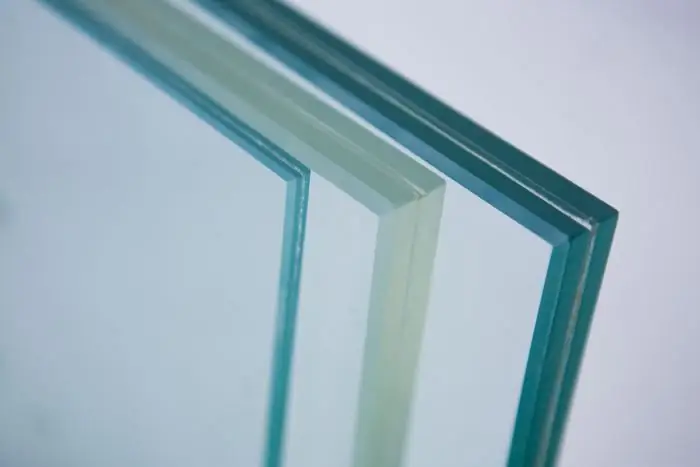

What is tempered glass: features of production, processing and applications

How is tempered glass different from regular glass? A description of the production process and the specifics of processing will help to find the answer to this question. Methods for determining tempered glass and possible options for cutting it without the use of special equipment

Titanium carbide: production, composition, purpose, properties and applications

Titanium carbide: the history of the discovery of this compound, chemical and physical and mechanical properties. Description of how to obtain it. Part coating, carbide steel fabrication and other titanium carbide applications