2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Literally translated from German, this word means - dirt. Sludge is a sediment of solid small particles that is formed during the filtration or settling of a liquid. In addition, it can be a powder formed during the electrolysis of metals. As a rule, such sludge contains microparticles of precious metals. And finally, sludge comes from drilling or crushing rock.

Drilling cuttings

This species is an aqueous suspension. It has a solid part, consisting of products obtained from the destruction of the rock, as well as the walls of the well. Drill cuttings are part of the suspension that is captured by the cuttings pipe during the core drilling process. Drill cuttings include four types of waste:

- spent betonite;

- clay;

- liquid soil;

- groundwater.

It is very important to properly dispose of drill cuttings. This is a task on which the well-being of the environment depends. Today there isseveral methods of disposal, but so far experts have not come to a consensus which one is more effective.

Oil sludge

This is a stable, multicomponent system. It consists of oil products, water and mineral impurities. Oil sludge is a product that is formed during the extraction, processing and transportation of crude oil.

Types of oil sludge

In accordance with the condition for the formation of sludge, they can be divided into three independent groups:

1) ground, which are formed when crude oil or oil products are spilled onto the soil (during production or in emergency situations);

2) reservoir - are formed during the transportation of petroleum products or during their storage in tanks of different designs;

3) bottom - this type of sludge appears when oil spills settle at the bottom of a reservoir.

The sludge generated during oil production is a separate group. Coming to the surface of the earth oily combustible liquid in its composition contains small particles of s alt and rocks, water, gases. This is the so-called crude oil. The impurities contained in it seriously impede the transportation and processing of petroleum feedstock. Therefore, pre-raw caustobolite is processed in a special way. Water, mechanical impurities, s alts and solid carbons are removed from it. Water is then re-injected into the oil reservoir (to maintain pressure). As a result, mechanical impurities with oil become oil sludge.

Currently processingmentioned substance is a necessary process. Thanks to him, it is possible to restore part of the oil product. Oil sludge, regardless of the nature of its occurrence, is harmful to the environment.

Today, the only way to dispose of them is by incineration or burial. These methods are very costly financially, require strict adherence to all technological standards. But at the same time, they do not give the desired result.

Yes, unfortunately, the ideal way to dispose of oil sludge has not yet been found. As in the twentieth century, traditional methods are most often used - burning, sedimentation, filtration.

Recommended:

Exploratory drilling: features, equipment. Assistant driller for production and exploration drilling

Exploration drilling is an activity aimed at finding raw materials in the bowels of the earth. At the beginning of the 19th century in France, they searched for water in this way. In the 50s of the same century, oil was searched for with the help of exploratory drilling

Oil is a mineral. Oil deposits. Oil production

Oil is one of the world's most important minerals (hydrocarbon fuel). It is a raw material for the production of fuels, lubricants and other materials

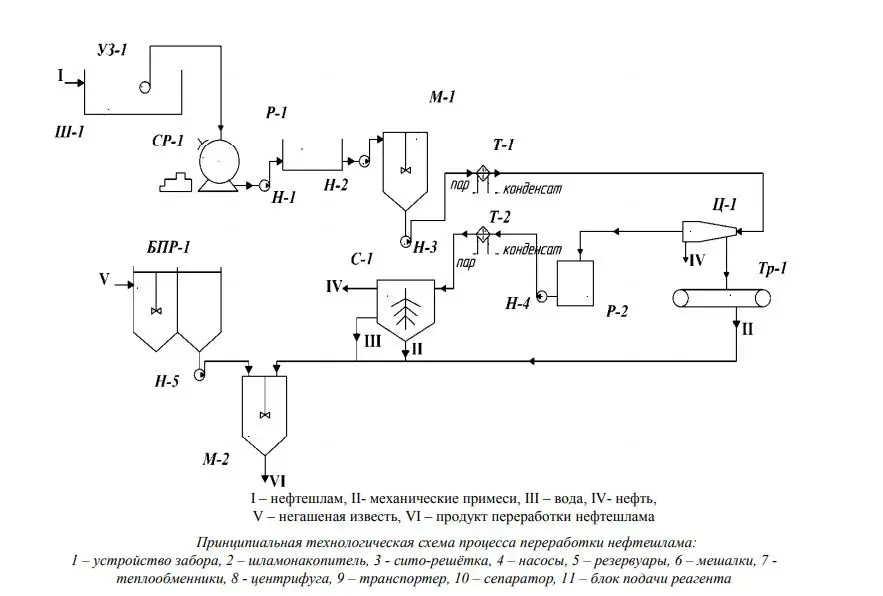

Utilization of oil sludge, removal and processing of oily waste

Oil refineries strive to optimize their technological processes as much as possible, reducing the volume of unused production products. But the thinner and deeper the processing of petroleum feedstock, the more dangerous the waste produced, which cannot be eliminated without third-party methods. One of the areas of recycling can be called the disposal of oil sludge as one of the most dangerous types of oily waste

Drilling is a type of mechanical processing of materials. drilling technology. Drilling equipment

Drilling is one of the types of material machining by cutting. This method uses a special cutting tool - a drill. With it, you can make a hole of different diameters, as well as depths. In addition, it is possible to create multifaceted holes with different cross sections

Overview of oil sludge disposal methods

Utilization of oil sludge: classification of processing methods, their advantages and disadvantages. Brief description of chemical, biological, thermal, physical and chemical technologies. Types of oil sludge. Applied equipment for their disposal