2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:30

The industry in which the use of assembly units is most pronounced is mechanical engineering. Machine assembly units are the smaller parts that make up a complete vehicle.

Definition

The use of such parts is carried out in various areas, but the essence of the assembly process does not change. It is also worth noting that before creating a unit, a drawing is made, according to which it is necessary to manufacture the part. An assembly unit is a part consisting of several parts, which, in turn, are connected by some assembly method. Their production is carried out by the manufacturer, which is engaged in the further assembly of the finished product.

It is worth noting that such a term as an assembly unit is not always used, more often you can find another name - a node. It is also important to note that in order to facilitate the assembly process, they are divided into smaller groups - subassemblies, and they are also assigned orders.

Product assembly

As mentioned above, the assembly of assembly units is carried out at the same plant that assembles the final product. This is clearly seen in the field of mechanical engineering. However, some types of products are fully assembled on site, for example, cranes or heavy presses. But it is important to note that even in such cases, when the final stage of the assembly of the object takes place along with its installation on the foundation, the initial process of assembling the unit or its individual parts, that is, assembly units, will still be carried out at the manufacturer of this product.

There are only a few exceptions where final assembly is not carried out at the factory. This applies, for example, to the assembly of aircraft or combines. The lack of installation of the finished product is argued by the fact that it is necessary to maintain the transportability of the units along the railway tracks.

Assembly elements

The first element, which is the basis for any product that is assembled in production, is the basic assembly unit and part, or just a basic part. There are structural assembly units and technological assembly units (assemblies).

Under a structural unit is understood a part that is designed only taking into account the functional principle. The conditions for independent or self-assembly of the part are not particularly taken into account here.

A node, or a technological unit, is a product of an assembly unit, the installation of which can becarried out separately from other components of the same unit or the whole product. Also, these nodes are able to perform their functions only together with other components. For example, you can take the cylinder head or block.

Units by orders

It is important to note that for assembly units there is a classification by order. The first includes those nodes, the installation of which can be carried out independently, separately from other parts. The same units that do not get into the finished unit directly, but through being part of any assembly unit, receive the second order, the third, etc.

Currently, for example, in mechanical engineering, the assembly is divided into two stages - this is the general, as well as the assembly of individual units. The latter includes those operations, as a result of which a first-order assembly is created from assembly units of the second, third order, etc. The general assembly includes all operations during which a finished unit is created from pre-prepared units of the first order. In addition, such an installation process can show the manufacturability of the process even at the installation stage. It is determined on the basis of whether it is possible to carry out parallel assembly of individual units and the finished product from these parts. If such a possibility is present, then this significantly reduces the time spent on completing the operation.

Drawings

To create any objects, you must first prepare a design document,which contains all the necessary drawings for the manufacture of parts or the finished product. There are several types of such documents, one of which is called assembly. It contains a drawing of the assembly unit, as well as other parameters that will be needed for direct assembly and full control over the final characteristics.

It is worth noting that assembly drawings are divided into several types: for electrical installation, hydraulic installation and pneumatic installation.

Assembly drawings are considered suitable for use only if they provide complete information about the assembly unit, about its design, about how exactly the various parts of this unit should interact with each other. Also, the paper should serve as visual technical documentation, which must be guided during assembly operations.

What is the drawing for

If there is an assembly drawing, operations such as:

- Assembly of the part, as well as its component parts, if any.

- Collective processing of several parts during the direct assembly of the unit or after the completion of this stage.

- Control of the received assembly unit.

In addition to these data, if necessary, the drawing may contain information about how the resulting product should work, as well as how exactly all its components should interact. Development of such documentscarried out for each unit separately. Drawing up an assembly drawing for each of the nodes should be carried out at the stage of preparing design documentation, since this paper is mandatory.

The initial data used to create an assembly drawing are general arrangement drawings, as well as a product specification. The details of the assembly unit, or rather the drawing for each component that will be included in the final node of the first order, must also be indicated in the documentation.

What should be indicated in the drawing

Based on GOST 2.109-73, we can say exactly what each drawing should contain.

- The first thing the document should contain is an image of the part, by which it will be possible to clearly determine the location of each part, as well as what relationship should be between them.

- The second required parameter, which must be indicated on each drawing, is the size, deviation or other requirements, the fulfillment of which is strictly mandatory.

- The nature of the conjugation should be indicated if it is not set by certain numbers, but is set by fitting parts.

- The method of establishing permanent connections should be indicated - welding, soldering, and so on.

- Full dimensions of the final part.

- Technical parameters of the finished product (only if necessary).

- You need to specify the coordinates of the center of mass (if there is such a need).

Assembly Types

Like most industrial operations, assembly units are divided into types by specialists. This division is carried out according to such characteristics as technological features of all types of units, depending on the method of their technological production.

There are five main types of assembly of assembly units - this is welding, soldering, gluing, forming from polymeric materials and using a threaded connection. In addition, there is a division into one-piece types of connections, detachable fixed, detachable movable, as well as detachable-one-piece.

The first type includes such types of connections as:

- welded;

- brazed;

- glued;

- harness;

- electroradio assembly;

- combined;

- pressed.

The second group includes such types of connections as:

- threaded;

- buttoned;

- pinned;

- bayonet.

The following compounds can be attributed to the third type:

- rectilinear;

- rotational;

- combined.

The last type includes the following types:

- crimp;

- lock;

- combined and others.

Classification

All the above classifications are considered to be in common use and therefore do not require any further explanation. But there are a few exceptions that still have an additional explanation due to their classification method.

Harness assembly units are products thatwhich consist of wires, cords or cables, they are fixed to each other with the help of threads, tapes, belts or with the help of any other insulating means made according to the drawings independently. However, you can also use materials that are made according to wiring diagrams, and not just according to drawings.

Recommended:

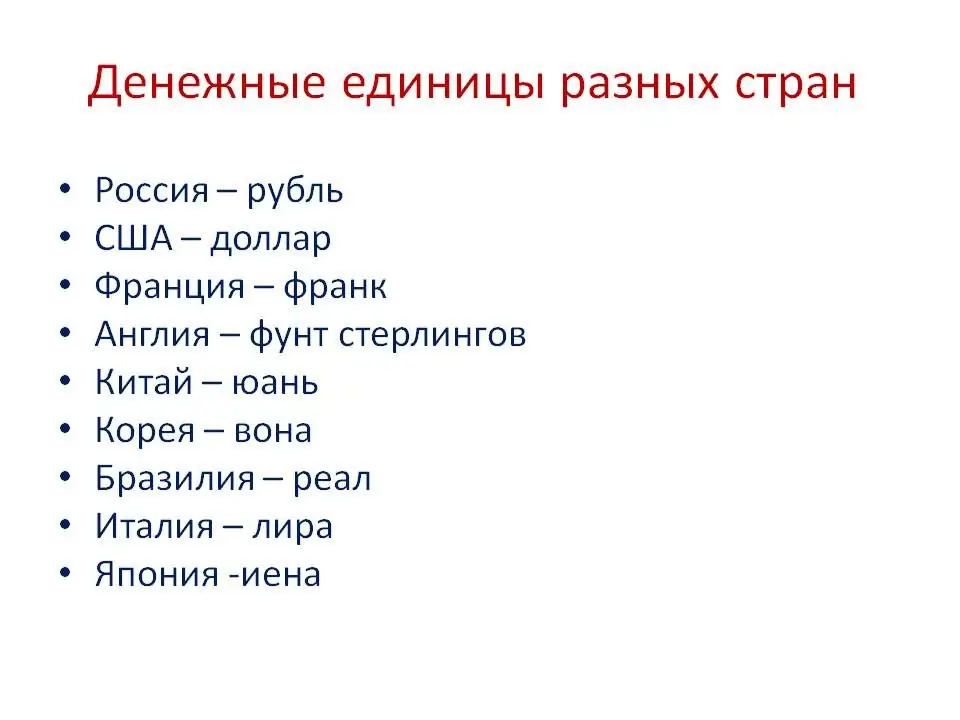

Monetary unit - what is it? Definition of the monetary unit and its types

The monetary unit serves as a measure for expressing the value of goods, services, labor. On the other hand, each monetary unit in different countries has its own measure of measurement. Historically, each state sets its own unit of money

The concept and types of organizations: definition, classification and features

The first organizations began to emerge in antiquity with the appearance of the first communities and tribes. They consisted of small groups, were very simple in structure and did not have complex goals. Now they have fully entered our lives, and without them there would be chaos and disorder everywhere. In the article we will consider in detail the types of organizations and how they operate

Classes of the Nice Classification: codes, list and classifier. What is the International Classification of Goods and Services?

For the registration of each mark of new products in business, the International Classification of Goods and Services is used. At the initial stage, the applicant determines under which category his activity falls. In the future, this will be the basis for the implementation of registration procedures and determining the amount of the fee paid by the entrepreneur

Tax and tax payments - what is it? Classification, types, concept and types

Currently, the tax system is a set of taxes and fees established by the current legislation of the Russian Federation, which are levied in the budgets of different levels. This system is based on the principles provided by law. Let us consider in more detail the issues of essence, classification, functions and calculation of tax payments

Main types and types of business plans, their classification, structure and application in practice

Each business plan is unique, because it is developed for certain specific conditions. But you need to familiarize yourself with the features of various types of business plans in order to understand their key features. Experts recommend doing this before compiling your own similar document