2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:32

Automotive equipment cannot work without fuel, lubricants and other materials. They have a number of special characteristics that depend on the features of the system. Operating materials correspond to the model of vehicles, perform many functions in the process of application. What they are, how they differ, will be discussed further.

General definition

Consumables are various materials that are used in vehicles, such as gasoline, diesel fuel or gas. These are expensive and environmentally unsafe compounds for which scientists are now looking for alternatives. Instead of natural resources, electricity is involved in the process. High demands are placed on modern materials that are used in the operation of a car. This is required to improve environmental safety.

All over the world, classic types of operational materials are still the most in demand. ATas energy for the movement of the vehicle, gasoline is used, as well as other similar substances of natural origin. But all this has a bad effect on the environment.

Consumables keep the vehicle systems in the desired form. To do this, each model involves the use of its own type of fuel and other compositions. For this, a system of special markings is used. Different vehicles have a different structure. Therefore, there can be no universal materials.

Varieties

There are three groups of materials that are used in cars:

- Combustible.

- Lubricants.

- Technical fluids.

Fuel can be liquid or gaseous. In the first case, it is gasoline and diesel. They convert chemical energy into mechanical energy by means of an internal combustion engine. Gasoline is used in spark-ignition piston engines, while diesel fuel is compression ignited.

Oils used in car systems are used to save energy, which is spent on friction. At the same time, lubricants ensure the safe operation of the vehicle. Depending on the field of application of the oil, there are:

- motor;

- transmission;

- turbine;

- cylinder;

- compression;

- reduced;

- electrical insulating;

- conservation;

- vacuum;

- specialized;

- instrument.

Ba separate category is allocated to greases, with the help of which sealing, sealing, preservation, etc. are performed.

Special technical fluids can perform different functions. They can be used in hydraulics as a working fluid, as a coolant, etc.

Petrol

When considering the performance characteristics of materials, it is worth starting with the most common type of fuel - gasoline. This is a refined product, which, along with diesel fuel, is a mixture of hydrocarbons, various additional additives that improve the performance properties of the fuel.

Gasoline contains hydrocarbons that can boil away when heated to 35-200 ºС. In diesel fuels, these components boil off at 180-360 ºС. Today put forward stringent performance requirements for materials, including gasoline:

- uninterrupted supply to the engine;

- formation of a mixture with air in the right proportion;

- combustion is normal, no detonation, complete inside the engine;

- at different temperatures contributes to a quick, reliable start of the motor;

- does not cause corrosion and premature wear;

- minimum deposits in the system;

- when storing and transporting, the original qualities are preserved.

Properties of gasoline

To meet the above requirements, gasoline must have a number of properties. The most important ones are:

- Carburation properties. Gasoline must form a fuel mixture with air, which must be homogeneous and completely burn out in the engine. To do this, gasoline must have certain indicators of density, volatility, viscosity, saturated vapor pressure, low-temperature properties.

- Combustion. This is the speed of the reaction of the interaction of hydrocarbons and oxygen, which is accompanied by a large amount of heat released.

- Normal and detonation combustion. In a normal process, the process is characterized by complete combustion of fuel, its oxidation. The speed of flame propagation in this case is 10-40 m/s. During detonation combustion, the speed increases to 1500-2000 m/s. In this case, the process is uneven, a shock wave occurs.

- Antidetonation. The composition includes tetraethyl lead, which is mixed with substances that prevent the deposits of lead oxides. They are called scavengers.

Diesel fuel

Considering the main operating materials, it is worth mentioning such a variety as diesel fuel. Due to certain features, this type of engine is 25-30% more economical than gasoline varieties. In most cases, diesel fuel is used for engines of buses, trucks, and some cars.

Specific requirements are put forward for diesel fuel during operation:

- Uninterrupted entry into the system.

- Promoting good mix formation.

- Should not cause corrosive wear.

- Bexhaust, intake tract, combustion chamber, no deposits should remain on the atomizer needle.

- Initial characteristics must be preserved during transportation, storage.

The most important properties of a diesel-type fuel are its volatility, flammability, and cooldown performance.

In the process of using operating materials, it is required to ensure a good start of the motor under any conditions. Therefore, the faction cannot be easy. Heavy varieties have better self-ignition. This ability of diesel fuel is estimated by cetane number (CN). This is a conditional characteristic, which is equal to the percentage of cetane in the reference mixture. It should be equivalent to the test fuel in terms of flammability.

The self-ignition index affects the tendency of diesel fuel to form deposits, engine performance and easy starting. In modern vehicles, a composition is used that is characterized by a CCH from 45 to 50 units. If the fuel has this indicator at the level of 40 units, the motor will work hard. Increasing the CN above 50 units is not advisable. The fuel will burn faster than it can spread through the chamber. Because of this, the operation of the motor is disrupted. Such diesel fuel will not be able to burn completely. Smoke will be observed, and the efficiency of the motor will be noticeably reduced.

Gas fuels

Automotive consumables also include gaseous fuels. According to their physical condition, they are divided into two categories:

- compressed;

- liquefied.

If hydrocarbons are characterized by critical temperatures, below the usual level, then the gas is used in compressed form. If the indicator is higher, then the compositions in the liquefied state are used. The main requirements for gaseous fuels are:

- good mixture formation;

- high calorie;

- should not lead to corrosive wear;

- minimum deposits in the system;

- preservation of properties during storage and transportation;

- low manufacturing and shipping cost.

Propane or butane is used to produce liquefied gas. They are easy to convert to a liquid state. For their designation, the CIS marking is used. Such materials are stored under pressure of 1.6 MPa. For cars, mixtures of propane and butane are produced, which can be used in summer or winter.

Odorants are added to the composition of the CIS, which give the mixture a strong odor. This allows them to be leaked.

Automotive operating materials also include compressed gases. Their main components are methane, carbon monoxide, hydrogen. They are obtained from gases of various origins. In the marking, such compositions have the letters LNG. Methane in such a mixture contains from 40 to 82%. This gas cannot be liquefied without cooling.

When using LNG fuel, it is possible to significantly reduce the carrying capacity of the vehicle. Vehicle mileage on a full tank in thiscase will be 2 times less than on gasoline. Since methane has a high knock resistance, engines are boosted in terms of compression ratio. CNG is safer than gasoline in terms of flammability. But at the same time, starting the engine at low temperatures is difficult.

Engine oils

Operational lubricants are allocated in a separate category. One of their varieties are motor oils. They provide:

- Reduce wear of moving parts due to friction by creating a strong and thin oil film on the surface;

- seal gaps at joints;

- heat dissipation from moving parts;

- removal of wear products, contaminants from friction zones;

- protection of metal elements from corrosion;

- Prevention of deposits of any kind.

Increased requirements are put forward for motor oils today:

- optimum viscosity in all operating modes;

- good lubricity;

- low evaporation, delamination and foaming;

- corrosion protection, low oxidation grease;

- low oil consumption during engine operation;

- long service life without damage to the system;

- preservation of qualities during storage and transportation.

The main qualities of the oil are viscosity and resistance to low temperatures. Today, three groups of motor oils are used:

- synthetics (completely artificial components);

- mineral composition(produced during oil refining);

- semi-synthetics (contains mineral and synthetic compounds).

There are certain rates of consumption of operational materials, which depend on many factors. It is worth noting that for synthetic varieties of lubricants, this figure is higher. The waste rate will be 30-40% higher than that of mineral compositions. Therefore, synthetic oils are changed much less often. These are more advanced compositions that can provide high-quality protection of components and mechanisms even under loaded conditions.

Synthetic oils have better viscosity-temperature characteristics, due to which the fuel consumption of the car is reduced by 4-5%. But at the same time, it is worth noting that synthetics are far from suitable for all motors. For new-style engines, this is the best option. But for motors with mileage that were installed on cars in the past, only mineral grease is suitable. The wrong choice of composition type leads to the rapid destruction of mechanisms.

Gear oils

Today there is a huge variety of operating materials used in car systems and other units. One of the varieties of lubricant products is gear oil. It is used to improve the quality of gears. Such mechanisms are used in transmission of various types. Hypoid (screw) gears are most often used in modern cars. They have stronger teeth than straight teeth. This ensures smooth, silent operation of the mechanism.

In order for the system to work smoothly, there are increased requirements for oils for such gears. This is due to the high sliding speeds. Gear oils perform a number of functions in the system:

- reduce mechanical wear of moving parts;

- reduce friction energy losses;

- contribute to the removal of heat from rubbing pairs;

- reduce noise, gear vibration;

- Provides impact protection;

- prevent the development of corrosion;

- in hydromechanical transmissions they perform the function of a working fluid.

The performance properties of materials are also subject to increased requirements. Depending on the conditions in which the lubricant works, the qualities of the material are also determined. The main parameters that affect the operation of the oil in the transmission are:

- temperature regime;

- gear speed;

- specific pressure in the contact zone.

The transmission oil is exposed to significant heat. Initially, it has the ambient temperature. Then, during operation, the heating level reaches 120-130 ºС. In some cases, the indicator can rise to 150 ºС. Therefore, the lubricant must be resistant to high temperature heating. In frost, the lubricant does not freeze, and when heated, it should not become excessively fluid.

Greases

There are some requirements for the quality of operational materials. A variety of compositions are being developed that can provide the correct working conditions for the equipment. One ofA commonly used substance in the vehicle system is grease. It has a thick, ointment-like consistency. This product consists of an oil base and a solid thickener.

Grease must have high conservation, anti-wear properties, chemical stability, heat resistance. For this, special additives are present in the composition. Greases can be:

- anti-friction;

- conservation;

- rope;

- sealing.

Considering the operational properties of materials, it is worth noting that each of the listed varieties has its own scope. Thus, antifriction compounds are used to reduce wear and friction of moving mechanisms. Conservation varieties prevent the development of corrosion during storage and operation. Rope and sealing compounds are used in the respective nodes.

Shock absorber fluids

Technical fluids include various operating materials. One of the varieties is a composition designed for body vibration damping systems. These are damping fluids that are used in telescopic shock absorbers. This allows the car to run more smoothly when driving on bad roads.

Low-viscosity liquids serve as a working fluid in the system. They are made mainly on an oil basis. The main indicator that is used to determine the properties of the damping fluid is its viscosity. Particularly high requirements are put forward to this characteristic at sub-zero temperatures. Otherwise, the performance of the shock absorbers deteriorates noticeably. The suspension may be blocked because of this. Therefore, synthetic-based formulations are used today.

Shock-absorbing fluid must have appropriate indicators of thermal conductivity, heat capacity, high lubricating properties. It should not be prone to foaming, oxidation. Important qualities are mechanical stability, volatility, compatibility with structural elements, especially with rubber seals.

Recommended:

Diamond boring machine: types, device, operating principle and operating conditions

The combination of a complex cutting direction configuration and solid-state working equipment allows diamond boring equipment to perform extremely delicate and critical metalworking operations. Such units are trusted with the operations of creating shaped surfaces, hole correction, dressing of ends, etc. At the same time, the diamond boring machine is universal in terms of application possibilities in various fields. It is used not only in specialized industries, but also in private workshops

Filter materials: types, characteristics, purpose

Modern production and ordinary consumers require purification of many substances. For this, various filter materials are used. What types of them exist and what properties they are characterized by, should be considered in more detail

Duration of the operating cycle. What is an operating cycle?

The company will not have problems with a lack of current assets if the management begins to strictly control the proportions between equity and debt capital, through which operations are financed

Steel support: types, types, characteristics, purpose, installation rules, operation features and applications

Steel poles today are most often used as lighting poles. With their help, they equip the lighting of roads, streets, courtyards of residential buildings, etc. In addition, such structures are often used as supports for power lines

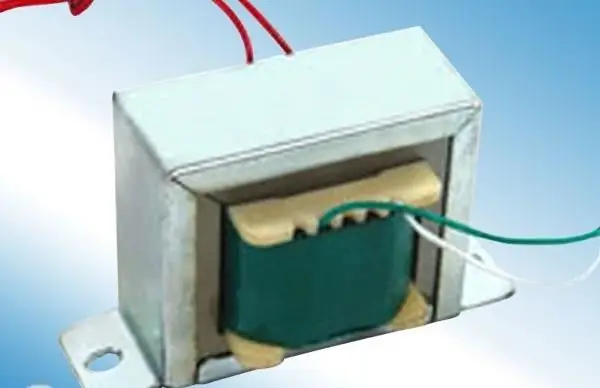

Single-phase transformer. Purpose, device and main characteristics

In practice, many repairers are often faced with the need to replace a burned-out single-phase voltage transformer. To ensure suitability, the characteristics of the replacement device should be examined