2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:33

Among Russian manufacturers of industrial equipment for bakery production, the brand from Saratov stands apart. Baking ovens "Voskhod" are excellent, especially if you focus on the "price / quality" ratio.

The assortment of the plant is wide enough to find something for a small "home business" level bakery, and for large-scale production. We will devote this article to the thermal equipment of the Saratov manufacturer.

Baking oven. General Requirements

Heating equipment for baking bread must:

- be able to vary the temperature range in the working chamber from 50 to 300 C;

- be able to provide steam humidification if necessary;

- have a high chamber for comfortable baking of bread in the form of L7 (the well-known high "brick");

- be able to adjustthe work of the upper and lower heating elements.

Common types of baking ovens

So, the following types of bread ovens are distinguished in production:

- Longline. The simplest version of the oven. Looks like a normal oven. Happens on 1, 2 and 3 tiers. Each tier is autonomous. Connection type - 380 V.

- Rotational. Used for baking bakery products in larger industries. They are a chamber into which a "hairpin" trolley is rolled in, on which baking sheets with flour preparations are installed.

- Tunnel. Factory scale production element. The tunnel baking oven works on the principle of a conveyor - at its beginning, dough pieces are laid out on the line, which subsequently go through a full cycle of heat treatment and by the end of the "path" they enter the stage of cooling and packaging. Such furnaces have autonomous thermal zones that can be configured in accordance with the technological map. In other words, the temperature inside the oven can be flat or change over a period of time.

- Cradle. From the name itself, the principle of operation of such furnaces is clear. Combines high performance with modest power consumption.

The hairpin is rolled into a rotary oven, where the products are baked evenly.

Voskhod deck baking ovens

The most popular positions from the assortment of the company. They are good in that the performance characteristics allow them to be used not only inbread production - many food service outlets buy for themselves, using confectionery and second courses for baking.

Why, thanks to the temperature of 350 C, this oven even bakes pizza! The only "but" - baking ovens "Voskhod" can not cope where there are capricious dishes. For example, meringue is unlikely to work in it. Popular models are as follows:

- HPE-500. It happens with a different coating - galvanized, painted, stainless. The first is the most budgetary, and practice shows that the coating does not affect the work in any way. The average price of such a furnace is 44,000 rubles. One-piece, but consists of three autonomous horizontal tiers. It has the possibility of steam generation (a special connector for water opposite each tier). Power - 19, 2 kW. Type of connection - 380 V. Temperature range varies from 50 to 350 C. The internal size of the chamber - 96.57625 cm. It is completed with six baking sheets 7046 cm in size (2 for each level);

- HPE-750/500.11. A complete analogue of KhPE-500, the main difference is one level, not three. Unfortunately, there are no "Voskhod" baking ovens on 2 levels in the size range of the plant, but, if desired, two such ovens can be stacked on top of each other in one working module. The average price is 28,000 rubles.

All furnaces of the plant exist both in the version with solid doors and with glass ones. The latter are more fragile, but are good because they allow you to control the cooking process without opening the chamber and without violating the temperature regime.

Rotary ovens "Voskhod" for baking bread

Rotational equipment at the plant from Saratov is represented by the following models of Musson-Rotor:

- Model 350. Execution - gas. For one load it is able to bake 360 pieces of pan bread in the form L7.

- Model 250 MP. Execution - gas. The amount of bread with a one-time load - 270 pieces in the form L7.

- Model 99/11-01. Execution - gas. For one load it is able to bake 180 pieces of pan bread in the form of L7.

These are quite expensive baking ovens, the average price for them is 700,000 rubles. Also, about 20% of the total cost of the equipment will need to be paid for the initial launch by the plant's specialists - otherwise it does not bear any warranty obligations.

Recommended:

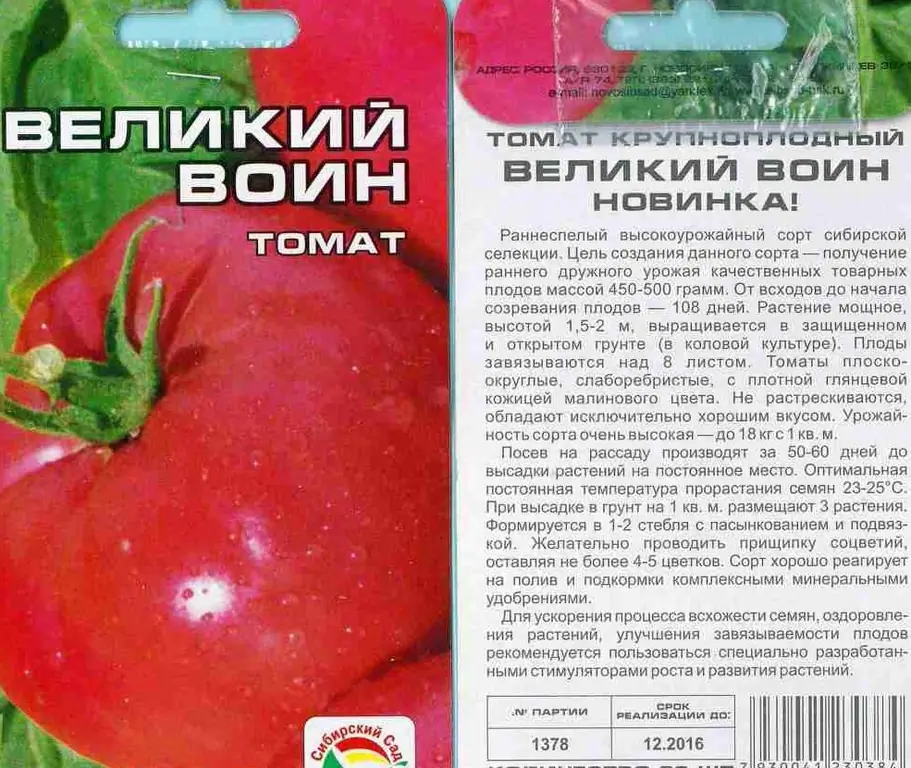

Tomato "great warrior": description, characteristics, reviews

The great warrior tomato variety was bred about ten years ago. During this period, it has become popular and in demand among lovers of large-fruited tomatoes. Its excellent taste qualities will not leave indifferent connoisseurs of this vegetable crop

Baking at home business: tips on how to open a pastry shop from scratch, the necessary equipment

If you like to please yourself and your loved ones with delicious muffins cooked by yourself, you should think about starting your own baking business at home. What you need to know in this situation will be discussed in the article

Characteristics of the Su-35. Su-35 aircraft: specifications, photo of the fighter. Comparative characteristics of the Su-35 and F-22

In 2003, the Sukhoi Design Bureau began the second in line modernization of the Su-27 fighter to create the Su-35 aircraft. The characteristics achieved in the process of modernization make it possible to call it a 4++ generation fighter, which means that its capabilities are as close as possible to the PAK FA fifth generation aircraft

Shaft furnace: device. Industrial ovens

The article is devoted to industrial shaft-type furnaces. The device of such units, their features, varieties, etc. are considered

Bread defects: photos, causes, baking problems and how to fix them

Bread making is a complex technological process. Not surprisingly, finished bakery products can have various defects. They can be caused by the poor quality of raw materials, the mistakes of the baker who kneads the dough and bakes it. It is worth noting that the flaws associated with the quality of ingredients are extremely difficult to fix, while technological flaws can be corrected. The article tells about the defects of bread and how to eliminate them