2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

There are a huge number of hacksaws today. All of them differ in their appearance, characteristics, etc. Also, these tools are divided into professional and home. The most significant difference between the two types will be the metal blade.

Sizes

Currently, 300 mm is considered the standard length for a web. There are also hacksaws, in which this figure is 150 mm. Shorter options are used only in cases where a large hacksaw is not suitable precisely because of its size or the craftsman needs to perform very delicate work.

If we talk about the teeth of the blade for metal, they are very small. This choice is due to the fact that it is small teeth that best cope with the task of cutting metal products. The masters of working with this tool pay attention to the fact that the canvas is the most important element, but it is worth paying due attention to the handle of the tool. For some types, it is made very unsuccessfully, and it will be inconvenient to work with such a device, even ifthe canvas for metal will meet all the qualities.

Differences between tools

As mentioned earlier, saws are conditionally divided into professional and home. The main advantage of a professional tool is that its design is more rigid, and also makes it possible to work at an angle of 90 and 55 degrees. Home appliances, on the other hand, are most often more flimsy, and during work they are constantly “stormed”. In this case, even a high-quality metal blade does not guarantee a high-quality cut. However, here it is already necessary to start from the frequency of using this tool. Home saws are much cheaper, and you should buy them only if the hacksaw is rarely used. If you have to use this tool quite often, then you should not save.

It is worth mentioning a separate type of saw - a hacksaw-handle. The main difference between this tool and a regular hacksaw is that it is designed to work with a broken metal hacksaw blade.

Product design

The design of this tool is almost the same for all models. The saw is a C-shaped arc, between the lower edges of which the blade is fixed or stretched. The working and main part of this tool is the same hacksaw blade for metal, which has many small teeth.

The handle is one of the three main parts of the device, plays a significant role in terms ofease of use of the tool during long work. Two-component composite handles with rubber inserts are considered the most successful in terms of performance and comfort of use.

The frame of this tool is an element that is designed to fasten a blade for a hacksaw for metal. In the manufacture of the frame, different materials can be used, but they depend on what type of work the saw will be used for. For example, if you need to cut high strength metals, then it is best that the frame is made of high strength composite materials.

It is important to note that the design of the frame largely determines the working conditions. If you need to cut in hard to reach places, then it is best to use a frame with blade angle adjustment or simply purchase a shorter version of the fixture.

Canvas

Hacksaw blade is a thin band made of hardened steel. Despite the fact that this is the only metal part in the design of the saw, it is also the most vulnerable to breakage, since the thickness of the product is very small. For this reason, when working with this tool, it is very important to monitor your actions. Careless and careless handling will lead to a quick breakage of a fragile structural element.

Teeth

The steel blade itself, the photo of which is shown below, cannot cut other metal parts.

The implementation of this process becomes possible due to the application of small wedge-shaped teeth to the edge of the web. It is very important to pay attention to the hardening of these teeth when choosing a tool. Proper selection will lead to the fact that the service life will increase significantly, as well as the efficiency of cutting the necessary parts. Currently, it is customary to use blades with fine teeth for cutting hard metal products, and large teeth are intended for working with soft parts. The canvases themselves can be made of different types of steel, but it is best to opt for bimetallic ones. If these could not be found, then you can pay attention to the red-hot canvases. These saw elements are made of nickel-plated stainless steel with teeth. It is worth noting that the web should be attached in such a way that the teeth go in the opposite direction from the handle.

Choose canvas

The quality of the blade is determined by its teeth. The first selection criterion is the shape of the cutting elements, which may vary depending on the inclination of the edge piece.

The second criterion for choosing a blade is the pitch of the teeth. By this parameter, you can determine what material hardness it is suitable for cutting, as well as choose the maximum possible thickness of the product that can be sawn. This indicator is measured by the number of teeth per inch of the web. It is also important to note that the thickness of the web for metal plays an important role here. For example, on a professional 300 mm hacksaw, the thickness will be 0.63 - 1.25 mm. Blade thickness for electric saws with a length of 150 mm - from 1.25 to 2.5 mm.

It should also be said that the number of teeth per inch of the blade depends on the thickness and material of the workpiece that will be sawn. For example, when sawing an aluminum workpiece with a thickness of more than 5 mm, it is necessary that the number of teeth per inch be 18. If the thickness is from 2 to 5 mm, then the number of teeth can vary from 18 to 24. If the workpiece thickness is less than 2 mm, the number of teeth should be between 24 and 32.

GOST linen for metal

GOST 6645-86 is a state standard that establishes requirements for the type, size, quality of metal sheets, etc.

This document sets out the rules for the technical production of this product. In particular, steel grades are prescribed in this GOST, from which it is necessary to make types of canvas. For example, type 1 must be made from a steel strip that meets all the requirements of GOST 23522-79. Type 2 hacksaw blade must be made of high speed steel, which is determined in accordance with GOST 19265-73. The document also states that the canvases must be subjected to heat treatment. Acceptable canvas is when the surface is free of cracks, captivity, scale or corrosion.

Recommended:

Detailed photo studio business plan. How to open a photo studio?

A good photograph is comparable only to a brilliant printed work that has not changed its content over the centuries, but at the same time every family wants to have it

How to choose a metal blade for a miter saw

Such a tool appeared on the market relatively recently. Metal cutting blade for a miter saw? For many, even experienced craftsmen, this causes a smile and distrust. Not so long ago, steel succumbed only to flame cutting, a circle grinder and a hacksaw. On cross-cutting machines, only wood and plastic materials could be processed. However, time does not stand still. Materials engineers in tandem with toolmakers are constantly working on the synthesis of new alloys

Diesel fuel: GOST 305-82. Characteristics of diesel fuel according to GOST

GOST 305-82 is outdated and replaced, but the new document, which came into force at the beginning of 2015, did not change the requirements for diesel fuel for high-speed engines so noticeably. Maybe someday such fuel will be banned for use altogether, but today it is still used both in power plants and on diesel locomotives, heavy military equipment and trucks, the fleet of which has been preserved since the days of the Soviet Union due to its versatility and cheapness

Extruded foam: specifications, thickness, density, thermal conductivity

The construction market today is overflowing with a variety of thermal insulation materials. They differ in production technology and their properties. However, one of the most popular is extruded foam, which will be discussed below

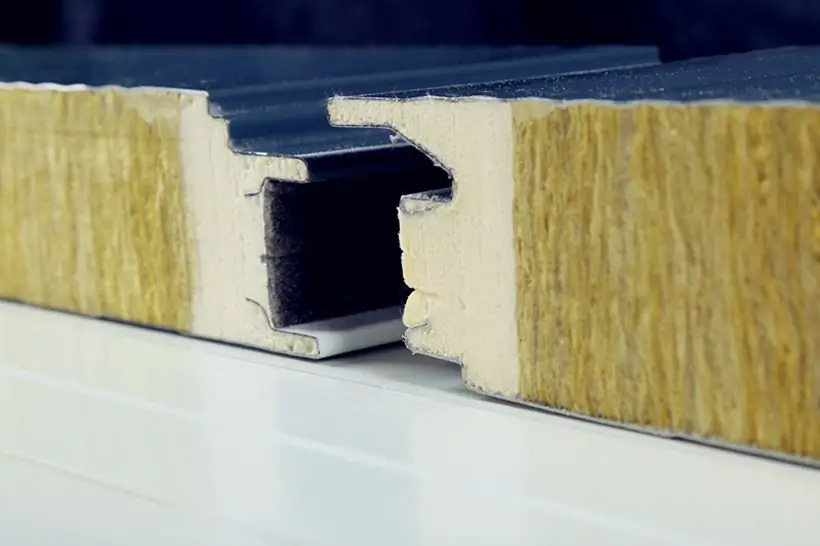

Thermal conductivity of sandwich panels: concept, main characteristics, dimensions, thickness, thermal conductivity coefficient, installation rules, pros and cons of operation

Thermal conductivity of sandwich panels will be the lowest if polyurethane foam is the basis. The parameter under consideration here varies from 0.019 to 0.25. The material is strong, dense and light. It is chemically resistant and does not absorb moisture. Rodents are indifferent to polyurethane foam, fungi and mold do not develop inside it. Working temperature reaches +160 ˚С