2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Polyamides have been around for a long time, but glass-filled polyamides are a new generation of this material. Their difference from conventional ones lies in the fact that the introduction of such a filler as fiberglass made it possible to obtain a product that is characterized by higher strength, rigidity, resistance to heat, as well as less cracking, which manifests itself under conditions of high and low temperatures.

Description and application

Despite the fact that glass-filled polyamide has improved almost all its characteristics, there are some that have become somewhat worse. This applies to the resistance of the material to its abrasion, as well as its elasticity. An unfilled substance has higher qualities.

With regard to the use of glass-filled polyamide, parts for precision instruments are made from it. In addition, it is also used for the manufacture of cam discs for electric tool cases. In order to improve the performance of glass-filled polyamide, substances such as graphite and molybdenum disulfide are also added to the composition. These supplements improvecoefficient of friction, and hence wear resistance. You can also use talc as an additive. It is used to obtain warp-like tags.

Types of polyamide

Today, such brands as PA and PA66 are quite popular. These glass-filled polyamides are characterized by high stiffness, strength and toughness. Good resistance to various aggressive environments is observed.

As for the benefits of using such polyamide, they are as follows:

- Viscosity, hardness and high resistance to effects such as thermal warping.

- The coefficient of friction and wear resistance is also quite high.

- These types of polyamides can be used at temperatures from -60 to +150 degrees Celsius.

- The properties of glass-filled polyamide allow it to function for quite a long time even under conditions of simultaneous exposure to factors such as high temperature, high mechanical stress, as well as exposure to substances such as oil, gasoline and other aggressive compounds.

This type of polyamide itself belongs to a composite material that consists of a polyamide type resin filled with pieces of glass filaments.

Description of cast polyamides

It is worth noting that there is a group of glass-filled thermoplastic polyamides, which are obtained during the casting process. They have a number of importantshortcomings. Among them, too low a coefficient of elasticity, a low coefficient of impact strength stand out most of all. In addition, the processing of such material is accompanied by a strong grinding of fibers of the reinforcing type. During this procedure, there is also a strong abrasive wear of the equipment.

Another property of fiberglass as a filler is its high density and low adhesion. Due to these factors, it turns out that the finished product is characterized by a high weight, and there is also an incomplete use of the safety factor of the fibers. These products also show poor moisture resistance and severe delamination.

GOST glass-filled polyamide

GOST 17648-83 regulates the quality requirements of the finished product, the technological process of its production, as well as safety requirements, acceptance rules and test methods for quality control.

As far as safety is concerned, polyamides of this type belong to the group of solid and combustible substances. This product can only be processed safely at temperatures up to 270 degrees Celsius. In this case, harmful fumes will not be released, and the material itself will not be subject to decomposition. There is no threat to human he alth.

If a base marked 66 is used in polyamide, then at temperatures higher than 275 degrees Celsius, the material will begin to decompose. At this time, carbon monoxide, ammonia and carbon dioxide will be released. Thesesubstances are already hazardous to human he alth. If polyamide marked 6 or 610 is used as the base, the maximum processing temperature may increase to 300 degrees before the product begins to decompose.

Recommended:

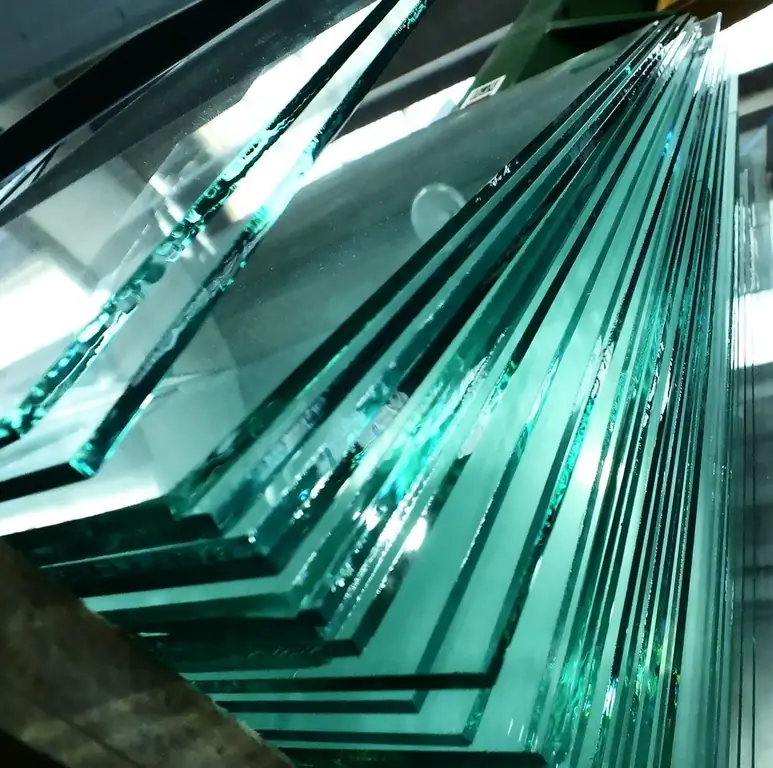

How to make glass? Glass production technology. glass products

Glass is familiar to everyone. But the process of making it is extremely exciting. Each stage is important and affects the quality of the final product. The basis is sand, soda, lime. The process is almost entirely automated. Surprisingly, glass can even be made at home

Glass sandblasting: glass processing description, equipment, application, photo

Among the numerous variations of interior decoration, sandblasting of a glass or mirror surface occupies a special place. This technology involves exposing the canvas to sand or other abrasive with a jet of compressed air released under high pressure. As a result, the surface changes and becomes matte, rough, velvety or painted with patterns. In the article we will consider what is sandblasting glass

Benefits when buying an apartment: types of benefits, government assistance, tax calculation and legal advice

The statistics in our country are disappointing: every second Russian has problems with housing. Some people save half their lives, others take out mortgages, others get in line for social programs. But people in any category will not forego benefits at the time of the transaction because they want to save money. So what are benefits and who do they apply to?

Grinding car glass. How to grind glass

The article is devoted to glass grinding. The grinding procedure, its tasks, technique, materials, etc. are considered

Glass factories in Russia. glass industry

The glass industry occupies an important place in the country's economy. Glass factories in Russia operate in almost every region. Window panes and portholes, bottles and dishes, household and interior items - without these items it is impossible to imagine modern civilization