2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Rolling machines are the most important equipment in obtaining metal in the form in which it is needed. They will be discussed in the article.

General information

Today, metal is the most common material from which a huge variety of things are made, from small household parts to large industrial facilities. However, there is a very important point that not everyone knows about. Simply smelting the metal and then turning it into an ingot is not enough. After the formation of the ingot, any metal is transferred to the rolling shop. The only equipment that is available in such workshops is rolling machines. It is these devices that give the desired shape, which is suitable for the subsequent use of metal. It is worth noting that this equipment is one of the oldest today. However, over the years of its use, the machine has proven itself from such a good side, has such good characteristics and productivity that it is still used today.

Machine device

In essence, the rolling machine device is not complicated or difficult to maintain, assemble or repair. The sole purpose of this device is to give shape to ingots of metal. In other words, large ingots enter the rolling mill, and as they pass through the rolling mill, they are shaped into more familiar sheet metal. In order to achieve this effect, the design of the rolling machine has two rollers that constantly rotate towards each other. From the point of view of the technological process, this work is considered quite simple. In addition, the constant improvement of technology has allowed many improvements and modifications to be made to the operation of this device. Thanks to these changes, all equipment of this type is now able to operate in a fully automatic mode.

Rolling

The rolling machine for metal performs another very important function. It doesn't just shape the leaf. As the ingot passes through this machine, the metal becomes more uniform and denser in structure. This is due to the fact that the rollers completely overwrite or close any cracks or empty spaces that could well be formed on the ingot.

Another important point - the process of turning or rolling metal into a sheet form takes place in several stages and with the participation of several types of machines. Primary rolling is carried out by blooming and slabbing devices. It is worth noting that beforeto send the ingot for rolling on these machines, it needs to be slightly warmed up. Raising the temperature of the metal will increase the plasticity of the material during its rolling. If we talk about the performance of such machines, then it is huge. One machine is capable of producing about 6 million tons of metal per year. This is taking into account the fact that the weight of ingots coming for hire can range from 1 to 18 tons.

Blooming or slabbing

Before rolling, the bars are heated in special wells. The temperature maintained in such devices can reach 1800 degrees Celsius. After passing the well, an electric car is used, which, in fact, gives out the heated ingot for rental of blooming or slabing. The difference between these machines is that blooming has only two rollers, while slabing has four. It is important to understand that the passage of this stage and the processing process itself are only primary, since at the exit from blooming or slabbing the ingot still does not have a full-fledged form of sheet material. These units are designed to form bars. Depending on its shape and size, the resulting material is divided into blooms or slabs. An important note - the use of blooming or slab rolling machines is carried out only at those industrial facilities where the metal will later be poured into molds.

General characteristics of the machine

Rolling mills are devices with smoothrollers through which metal is passed in order to give it a sheet shape. Currently, there is a huge range of these devices. The biggest difference between the machines is in the shape of the rollers. For example, there is a unit that was originally made for the production of rails. The shape of its rollers was prepared precisely for this task during the production of the machine. It is also important to understand that the machine has several pairs of rollers through which the metal passes. Constant progress has led to the fact that all types of devices are able to work in a constant automatic mode. The speed at which the stands pull the ingot through the machine can reach a record speed of 290 km/h. The annual capacity of such a rolling mill reaches several million tons. To date, such units as casting and rolling are gaining great popularity. The advantage is that they can act as a separate complete production line, unlike conventional rolling mills.

Currently, there are types of machines such as blank, sheet, strip, bar, and some types are capable of producing wire or beams.

Pipe rental

Another large category of rolling machines is intended for the production of metal pipes, not sheet metal. There are only three main types of pipe rolling machine that are currently in use. These include piercing, rolling and finishing machines.

If we talk about piercing mills, then they can have three different types of rollers used for rolling. There are barrel-shaped, mushroom-shaped and disc rollers. A device of the first type, i.e. barrel-shaped, is characterized in that these machine elements have a double-tapered shape with a diameter of 450 to 1000 mm. Both parts are located in the horizontal plane, but along the vertical axis, you can adjust the feed angle from 5 to 18 degrees or more.

Rolled screws

The profile pipe rolling machine can also perform metal screw processing. This type of operation in double-cone rolls creates tensile and shear stresses in the metal. It is important to note that the radial stress of the workpiece can reach quite large values, which creates a cavity of small diameter, which has uneven walls. In order to obtain a hole with the required diameter and at the same time avoid the presence of irregularities, and make even walls, it is necessary to roll on a mandrel. A mandrel is understood as a cone-shaped tool, which is located at the end of the rod between the rolls along the path of movement of the metal workpiece. There is a special stop for fastening the rod with such a mandrel. As the metal moves forward, it is pierced by this frame, which passes through the hole, expanding and flattening it.

Reviews about a rolling machine for a profile pipe are quite problematic to collect, since such units are used inmostly for big companies. However, here the very use of these particular units already indicates that they work stably and well. In other words, conclusions can be drawn from the fact that for a huge period of time all metalworking factories use such machines. And this means that the presence of an automatic mode and huge performance are doing their job. The disadvantages include the fact that the dimensions of such devices are quite large, and stopping them and restarting them is very problematic.

Thin tubes

It is worth noting that when rolling on piercing machines, thick-walled sleeves are obtained. After processing on this device, the workpiece is transferred to thin-tube rolling on a device such as:

- pilgrim;

- automatic;

- continuous;

- three-roller.

The name of each of these units is determined by the type of rolling mill used on this equipment.

Punch machine

The most famous manufacturer of this unit is Kadzama. This device is also called a roller press. The device of this thing is very simple, and it is intended for cutting cardboard, paper or plastic boxes for confectionery.

The advantages of this device include the fact that it pays off pretty quickly. The first 10,000 boxes - this is the approximate cost of one such machine. The cost of finished products, that is, boxes, is also very low. You have to pay only for the originalmaterial - cardboard. It is very easy to work with this type of machine. All it takes is just two things. First, a sheet of cardboard is placed on the punching knives, and then the feed handle is turned. The dimensions of such a device are also quite small. You can even install it on a regular table.

How to make a rolling machine?

In order to make a rolling machine for the production of profiles, you will need 3 mandatory things - this is metal, bearings and a lathe. The very same design of the machine is also quite simple. The constituent parts of a one-piece rolling machine is a table to which a worm gear motor is attached. In addition, it is necessary to fix 7 additional receiving stands on the table. It is important to know here that each cage consists of several components, and also they all have engagement with each other. That is, each cell is connected to the next. One more nuance concerns rollers. In this model of the machine, they are removable, and their fastening is carried out on the shafts. This type of arrangement and the type of rollers itself opens up wide opportunities for the production of various profiles in terms of their dimensions, as well as the type of product. If there is such a desire, then you can put a new type of rollers that will make it possible to produce an LSTK profile. In order not to be mistaken in manufacturing, it is best to draw a drawing of a rolling machine before proceeding with its assembly.

Recommended:

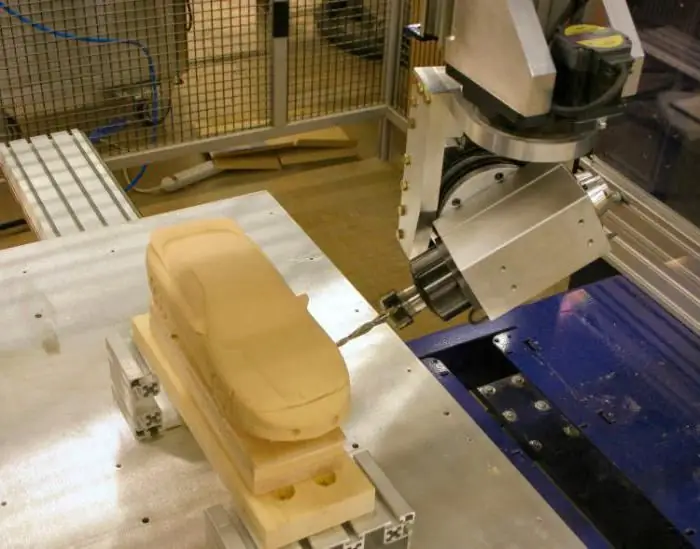

CNC small business machines - overview, types, specifications and reviews

CNC machines for small businesses: types, descriptions, features, photos. CNC machines for small businesses: overview, specifications, reviews

Machines for furniture production: types, classification, manufacturer, characteristics, instructions for use, specification, installation and operation features

Modern equipment and machines for furniture manufacturing are software and hardware tools for processing blanks and fittings. With the help of such units, craftsmen perform cutting, edging and adding parts from MDF, chipboard, furniture board or plywood

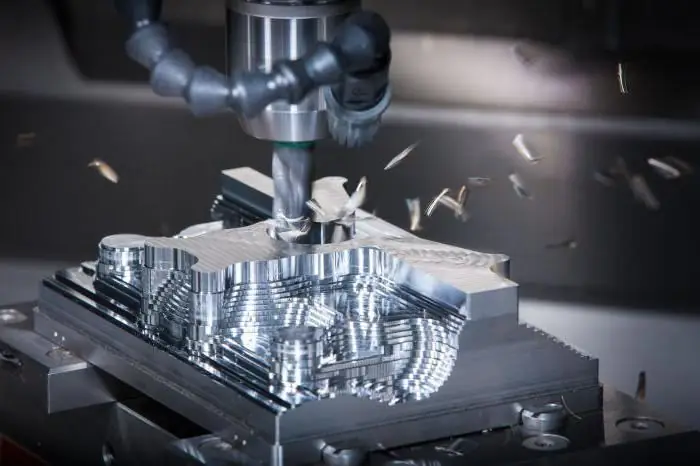

CNC machines for metalworking: overview, specifications, types and reviews

CNC machines for metalworking are used in almost every machine-building, pipe, repair plant. Modern cutting methods are intensive. The control systems are based on one service center, which is able to monitor the status of the working axes and the surrounding automation in real time. LCD screens provide information in a convenient 3D graphical format

Dough rolling machines - purpose, overview of models

In any bakery that has gone beyond the scale of "baking for family and loved ones", dough moulders are needed. What are they needed for? Do you remember the orderly rows of loaves in the bakery departments of stores. Size and appearance - one to one. This cannot be achieved by hand molding. No matter how delicious your bread is, appearance is very important to the consumer. Delicious, beautiful and smooth pastries will be much more in demand than just delicious

Traction rolling stock: classification, types, device and characteristics

At present, the railway communication is developed quite strongly. In order to move massive wagons, traction rolling stock is used. To date, such trains include locomotives, as well as multiple unit rolling stock