2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

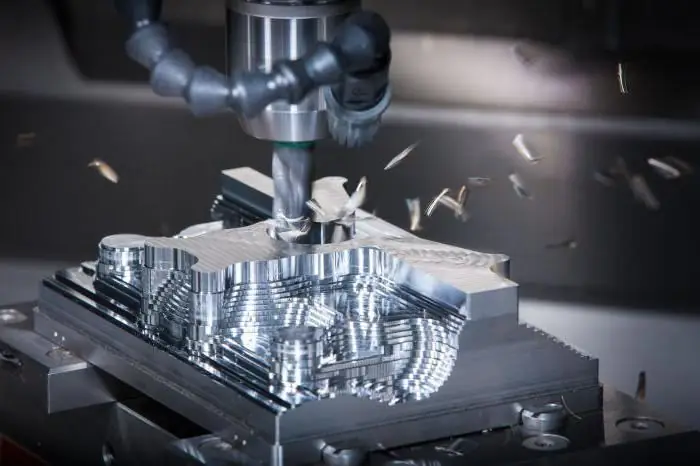

CNC machines for metalworking are used in almost every machine-building, pipe, repair plant. Modern cutting methods are intensive. The control systems are based on one service center, which is able to monitor the status of the working axes and the surrounding automation in real time. LCD screens provide information in a convenient 3D graphical format.

What does program management consist of?

CNC metalworking machines are used for the production of precision machine parts, pipe threading. The price of installations ranges from several thousand (desktop models) to several million (multi-axis machining centers) rubles. A suitable model is selected according to the tasks of production. The cost is reduced by choosing conveyor versions. Single projects are estimated at a significant amount, because it is required to create drawings with almostzero.

At the heart of the machine is a controller that defines the following positions:

- Basic anchor points.

- Movement coordinates along a given trajectory according to the control program.

- The state of analog and discrete sensors is analyzed. These include motion, level, pressure, temperature controllers.

- Signals from drive systems, controllers from lines coordinated with the machine are monitored.

- Signals are exchanged with upper level systems.

- Built-in interfaces make troubleshooting easier.

- The control program issues error codes on the monitor. It is easier for the installer to find the emergency node.

CNC machines for metalworking are equipped with innovative security systems that even experienced electronics engineers cannot bypass. This increases the reliability, safety of operation of the machines and preserves the manufacturer's warranty.

Complete sets

Dimensional accuracy is achieved using servo motors, stepper systems, rulers or encoders. Spare parts quickly fail due to the aggressive environment in enterprises. Coolant coolant is required when metalworking is performed on machine tools. Almost all production facilities work with CNC in Moscow. Western designers are introducing modern signal transmission systems with high bandwidth. This allows you to produce products at an incredible rate.

Pause for changeovers may not exceed a few seconds, which makes product manufacturers leaders in the industry. Time costs are reduced, and this is reflected in the cost of final products. The process chain line can be operated by a single operator without the involvement of expensive specialists.

Mechanics

Modern materials reduce the effect of vibration on the frame. Wear-resistant kinematic systems provide a specified mode of trouble-free operation. Temperature sensors transmit information about the condition of the thrust bearings, hydraulic system, lubrication and cooling tanks. If there is a lack of oil flow to the main loaded unit - the spindle - a malfunction message is displayed. This allows you to maintain the integrity of an expensive item.

Before starting work, the automatic system heats up the lubricating oil. Pulse dosing of the substance on the guides is carried out by timers. Drive systems constantly monitor the load on the kinematic units during movement. After the cutoff current is exceeded, a stop alarm is issued via the controller. After the fault is eliminated, the error is acknowledged by the installer.

Optional equipment

Operator panels can be equipped with a hard disk. It stores all the data of archives, changes in programs, improvements in cutting technology. This option allows you to install an operating system that restores the machine to a short overwrite. So, in the event of a failure of the control board in the memory of a newDevices transfer codes in minutes. Equipment downtime is minimized, the company does not suffer losses in case of an accident.

CNC metalworking machines are equipped with Wi-Fi transmitters, which provide wireless transmission of line status for hundreds of meters. The server collects results about finished products. According to managers, this refinement helps to control the state of the production process without leaving the office.

Manufacturer comparison

Russian-made CNC machines for metalworking do not differ in quality and reliability from machines of Western competitors. The software is more accessible due to its free download on Internet services. Western companies are still leading due to the productivity of control centers. Designers "sharpen" the equipment for the needs of technology in a prompt manner.

Leading design bureaus founded decades ago. A team of professionals is able to update machine versions quarterly. Russian analogues appear much later. But due to the low cost of installations, there is always demand.

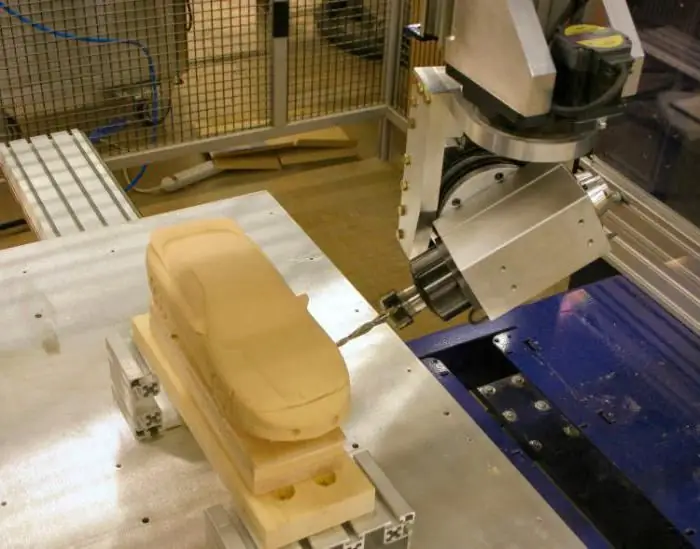

Desk types

Simple and inexpensive desktop CNC machines for metalworking have become popular. Training, production of small parts or the need to frequently change the location of the installation are the main objectives for the acquisition of such models. Compact systems are bought by manufacturers of printed circuit boards, electronics parts.

CNC machines combine two beneficial factors:

- Low cost.

- Reliability and long-term non-stop operation.

Widely used in the technology of cutting sheet materials. The machines are powered by a 220 V network, which allows you to place a working unit in a garage.

Classification of machines

CNC machines for metalworking are divided by dimensions, purpose, type of cutting, control method. Each type takes into account the characteristics of a particular production. So, pipe parts require several types of machines. Entire lines of systems are concentrated in one enterprise, stretching for hundreds of meters.

There are several types of machines:

- milling;

- engraving;

- turning;

- grinding;

- plate bending and pressing equipment.

By design, they are divided into the following types:

- portal systems;

- vertical;

- horizontal.

Cars are more likely to buy multi-axle. According to manufacturers, even for the manufacture of simple products, at least two planes of movement of the working tool are required.

Types of metalworking

Metalworking on CNC machines in St. Petersburg is offered turning, engraving, thermal. All technologies are carried out in an automatic cycle. It takes a minimum amount of time to complete an order. You do not need to spend on changeoverextra effort. The database contains the main technological programs, it is enough to download a three-dimensional model of the part from a portable medium.

The final products are controlled by the quality control department. Experts analyze surfaces using modern equipment. The accuracy of the manufactured parts allows companies to take orders from the military and the space department. On CNC systems, they achieve the manufacture of blanks in 5D planes due to additional axes of movement of the spindle assembly. According to manufacturers, with this opportunity, it turns out to work out all the technological holes in one cutting cycle.

Recommended:

CNC small business machines - overview, types, specifications and reviews

CNC machines for small businesses: types, descriptions, features, photos. CNC machines for small businesses: overview, specifications, reviews

Copper radiators: overview, specifications, types, installation features and reviews

Copper radiators are appliances made of an amazing metal, it does not corrode, excludes the reproduction of microorganisms, and is also not afraid of chemical reactions

Tire changer for trucks: overview, specifications, types and reviews

The article is devoted to tire changers for trucks. The characteristics, varieties, reviews and nuances of choosing this equipment are considered

Industrial refrigerators: overview, description, types, specifications and reviews

Most people deal with equipment like refrigerators every day. But this technique is designed for the home. What devices are in production? After all, products are sold in large volumes. Industrial refrigerators are entire structures that are a refrigerating chamber for cooling or freezing food

Industrial sewing machines: overview, description, classes, specifications and reviews

Industrial sewing machines are made in various types and have their own class. In order to understand the models, you should consider the main manufacturers and find out consumer reviews