2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Quality service in a car service is impossible without modern technological equipment. For a tire shop, a stand (or machine) occupies a central place in the list of tools, on which the operations of removing, pressing and installing rubber are directly performed. For trucks, massive machines are used, which are also capable of providing a higher force impact. But even in this segment there are different offers, options and modifications of equipment. Knowing its features, technical parameters and functional equipment will help you choose the right tire changer for trucks.

What is the design of the booth?

The components of a typical stand can be divided into several groups - bearing elements, clamping equipment, power mechanisms and auxiliary devices. The load-bearing elements include an easel platform with legs or supports - this part is implemented in different ways, but in any case, stability and stability are important for it. As for clamping devices, they areconsole, hydraulic equipment, spring and in some operations a turntable. The power filling is already involved in the working process, which drives the tire changer. The description of this piece of equipment depends on the type of drive, but in modern machines it is implemented by pneumatics. This mechanism saves the operator's time, coping with heavy loads. In some models, the manual principle of operation is still preserved, but it is more typical of stands designed for servicing cars. Machine tools for trucks today gravitate more towards automation, which will be discussed below.

Varieties

Indeed, the division by type of drive can be called the key in relation to the classification of tire changers. Again, it makes no sense to consider manual mechanics, since it has been preserved only in museums, but not in modern car services. If we talk about traditional and conservative solutions, then these will include semi-automatic units. They use hydraulics or pneumatics as a power unit, but the operator puts it into action - also manually, but with minimal effort. These are cheap machines that are distinguished by their reliable design, but even their outwardly modern appearance does not save them from technological obsolescence against the background of fully automated analogues. The possibilities offered by the truck tire changer stand go far beyond the scope of ergonomics alone. Interaction with drive andthe functionality of the unit is carried out by means of a remote control - wired or remote. The operator sets the speed, clamping force and other parameters with which the machine will work. Next, by pressing a single button, the user starts the workflow. In several stages, the technician independently updates the wheel.

Performance

The main performance characteristic is the diameter of the wheel, with which the machine can, in principle, work. But along with it, you need to take into account the width of the product. As a rule, these are interrelated parameters. So, the maximum wheel diameter for trucks is 90-98 inches. This is the limit, at least for common equipment that often uses tire fitting services. These values should be guided as the maximum indicator of the diameter of the tires. But this does not mean that this value should be finite. The middle segment should also not be overlooked. Universal machines, for example, can also handle 59-63 inch diameters. As for the width, it is better to select equipment for truck tire fitting, designed for a format of 30-59 inches. A wide coverage will also be beneficial in this case, as the workshop will receive more customers.

Power Specifications

Machines are usually powered by an electric motor. Another thing is that some models are powered by a 220 V mains supply, while others are powered by a three-phasesockets 380 V. In general, the power range can be represented in the corridor from 1 to 3 kW or more. It is in the case of truck wheels that we are talking about exceeding the threshold by 3 kW and, accordingly, about connecting to a 380 V network. But there are exceptions in this category too, if a pneumatic drive with a compressor unit has been introduced into the working infrastructure. Such additions minimize the load on the network, replenishing it with a supply of pressurized compressed air. But will a combined tire changer for trucks justify itself in practice? It will fully justify if energy efficiency issues are at the forefront. Pneumatics reduce not only the force from the electric motor, but also the cost of electricity. True, connecting the compressor technically complicates the complex and requires deeper maintenance.

Machine dimensions

Car service stands are famous for their large size, but in this case we are talking about a small area. For modest-sized machines, 6-8 m2 is required, taking into account not only the equipment itself, but also the technological service area. If every centimeter in a cramped room counts, then you should give preference to small-sized stands - on the market you can find boxes with parameters of 90 by 100 cm. But even in this case, there is a risk of excessive constraint on the workflow. Therefore, equipment for truck tire fitting in the format of 180-200 cm will still be the best solution. Plus, there should be about a meter radius for freedom of movementinstaller.

Functional support

The fashionable trend among manufacturers of tire fitting equipment has become the inclusion of third-party stands in complex stands. This is an option that allows the operator to apply pressure to the bead of the tire during mounting on the rim. In addition, the "hand" copes well with low-profile rubber, which is often abandoned in conventional workshops. A modern tire changer for trucks is less and less complete without a tire inflation function. Using the complete gun connected to the same compressor, the operator can fill a truck tire with air in just a few minutes.

Question of price

The cost of the stand is determined by many factors, including technical characteristics, dimensions, optional kit, power stuffing data, etc. If we talk about the entry level, then a truck tire changer in Moscow can cost 50-70 thousand rubles. It will be a solid design with a minimum set of additional functions and average power, but it will be suitable for performing typical actions.

In terms of manufacturers, it is better to turn to the brands Trommelberg, AE&T and Sivik. These are specialized vehicle equipment manufacturers trusted by professionals. Another thing is that it will be an expensive tire changer for trucks, the price of which, even in the middle category, can reach 200-300 thousand

Expert advice on choosing

Professional workshop staffrecommend focusing on high-tech solutions. They allow you to attract new customers with their novelty and functionality. As for the design and dimensions, it is advisable to look into the future in this part. The machine should be compact, which will make it possible to expand it optionally by adding other tools to the working area. For example, a powerful truck tire changer that runs on 380 V will definitely require an addition in the form of a generator set. In the event of power surges, it can replace the power supply.

Conclusion

The latest bodyshop fittings are less about performance and more about ergonomics and functionality. Moreover, the efficiency is also not satisfactory. Automation adequately copes with its tasks even without the direct participation of the operator. Moreover, truck tire changers, tire inflation stands and boxes are actively interfaced with computer diagnostic equipment. The simplest example is an indication system that not only records the pressure readings and notifies the operator about them, but also provides information about temperature, rubber condition and other properties of the serviced product. Expansion of diagnostic capabilities, in turn, allows you to more accurately coordinate the work of the mechanics of the stand, which is a new stage in the development of tire fitting equipment.

Recommended:

CNC small business machines - overview, types, specifications and reviews

CNC machines for small businesses: types, descriptions, features, photos. CNC machines for small businesses: overview, specifications, reviews

Copper radiators: overview, specifications, types, installation features and reviews

Copper radiators are appliances made of an amazing metal, it does not corrode, excludes the reproduction of microorganisms, and is also not afraid of chemical reactions

Industrial refrigerators: overview, description, types, specifications and reviews

Most people deal with equipment like refrigerators every day. But this technique is designed for the home. What devices are in production? After all, products are sold in large volumes. Industrial refrigerators are entire structures that are a refrigerating chamber for cooling or freezing food

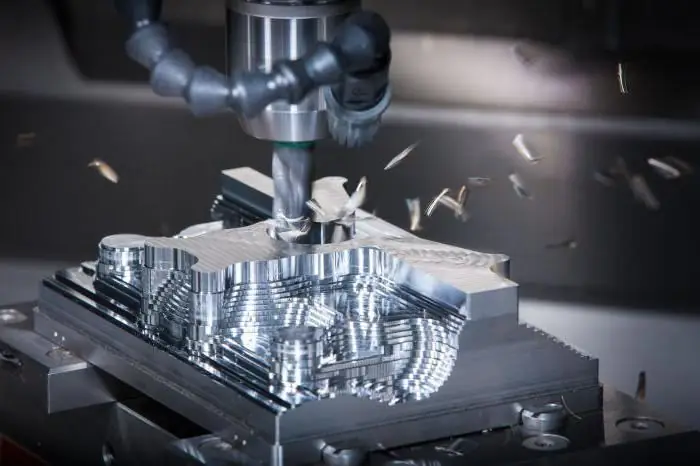

CNC machines for metalworking: overview, specifications, types and reviews

CNC machines for metalworking are used in almost every machine-building, pipe, repair plant. Modern cutting methods are intensive. The control systems are based on one service center, which is able to monitor the status of the working axes and the surrounding automation in real time. LCD screens provide information in a convenient 3D graphical format

Tire service business plan: sample, example. How to open a tire shop from scratch

Tyre service can bring a good income. Before investing in your own business, you should draw up a competent business plan