2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:38

PPU insulation is considered the most effective today, since this material has the lowest thermal conductivity, and also has excellent waterproofing properties. The latter characteristic is due to the presence of 99 percent of closed pores in the composition of the material. Polyurethane foam insulation is neutral to chemicals, alkaline environments and acid compositions. It belongs to the G2 flammability class and has a high resistance to external influences.

General Description

Rigid polyurethane foam has excellent heat-saving qualities with a small layer thickness. Thanks to these properties, it is suitable for solving professional thermal insulation tasks, which, for economic and technical reasons, require optimal energy savings. Water absorption of the material does not exceed 1.2-2.1% of the total volume. The insulation is flame retardant even when exposed directly to fire.

PPU insulation has a low weight, which varies up to 60 kilograms per cubic meter. It is characterized by excellent strength and anti-corrosion protection of metal structures. During installation, there is no need to use additional fasteners, no cold bridges are formed in the process. It is possible to isolate with the help of this material designs of any configuration and size.

Durability

PPU insulation is durable, due to the fact that the material is not subject to decay and does not resolve under the influence of seasonal fluctuations in humidity and temperature. It is impossible not to mention the high environmental friendliness, so, according to hygienic standards, the material can be used in cold equipment, which is intended for storing food products.

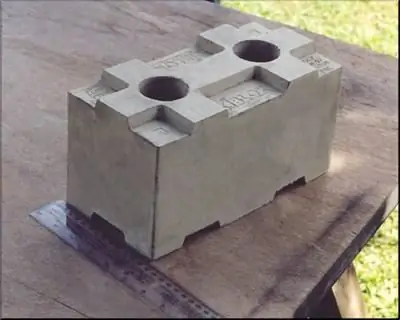

Insulation is made using the technology of pouring polyurethane foam into a mold, with the help of which it is possible to form blocks called shells. They are used for the arrangement of pipelines, the manufacture of sandwich panels and slabs. Polyurethane foam can be sprayed on any materials such as metal, wood, brick, glass, and concrete. In this case, the surface configuration does not matter.

Production of PU foam pipes

PPU insulation, the production of which will be described below, is used in the manufacture of pipes requiring special protection. The result is a thermally waterproofed product, which is manufactured in accordance with GOST 30732-2006. In this case, polyurethane foam is used as the thermal insulation material, while moisture protection is guaranteed by the presence of a polyethylene layer. Such pipes are intended for the arrangement of heating mains, the installation of which is carried out underground. In the processin the production of such three-layer systems, high-quality steel is used, with the help of which the coolant will be transported.

Products are protected by a polyurethane foam layer, which completely eliminates heat loss. Steel and polyurethane foam are protected from groundwater, which is ensured by the presence of a special cover, which is made of polyethylene. Steel pipes in polyurethane foam insulation can be of two types, each of which involves the use of its own thickness of the insulation layer. The first type is used for installation in central regions, the conditions of which are characterized by a temperate climate. The second type is designed to operate in conditions of particularly low temperatures, with regard to the northern regions. PPU-insulation (shell) during the production process is supplied with the UEC system, which allows you to timely detect damage that occurs during operation. It allows you to control the humidity of the insulation layer, signaling when the level rises.

FPU prices

PPU insulation, the price of which is presented below, can be the only right solution if you need to insulate pipes. Thus, if you need an additional system, then with a pipe diameter of 507 millimeters, a wall thickness of 3.5 millimeters and a shell diameter of 125 millimeters, the price of insulation without a steel pipe per linear meter will be 376 rubles. With an increase in the above parameters to 89x3, 5x160 millimeters, the price increases to 552 rubles. The impressive dimensions, equal to 630x8x800, imply a cost of 8600 rubles.

Positive sides of PU-insulated pipes

If you decide to insulate pipes using polyurethane foam, you can count on the high-tech characteristics of the material. Among them, one can single out an insignificant coefficient of thermal conductivity, which is 0.027 W / mk. Not to mention the strength, as well as resistance to corrosion. PPU will protect the steel pipe better than armored concrete or bitumen perlite. The steel surface does not need to be treated with an anti-corrosion coating, which will provide more impressive heat retention than mineral wool insulation. After carrying out such work, the pipes will be able to serve for 25 years or more. This is several times longer than the time that is given to pipes without appropriate processing. If you have a UEC system, you will be able to control the integrity of the product during operation, eliminating earthworks. It is worth highlighting the economic advantages, which are expressed in the fact that the use of pipes with polyurethane foam insulation reduces the installation time of heating networks by three times, reduces maintenance costs by 9 times, but as for repair work, they will be 3 times cheaper.

Conclusion

If you use pre-insulated pipes in the manner described above, you can significantly reduce the cost of construction and subsequent operation. You will have the opportunityminimize the loss of degrees of heat, which when using such pipes is 2%. Products in polyurethane foam insulation can be operated at impressive temperature ranges, which vary from -80 to +130 degrees, which is very suitable for difficult conditions in some regions of Russia.

Recommended:

Foam block: foam block dimensions, history of appearance and application prospects

Each movement of the bricklayer is performed at a certain speed. An ordinary clay brick weighing about 3 kg or a large foam block of the same mass will be installed in the wall in the same time. But the dimensions of the foam block are eight or even twelve times the size of a brick, which dramatically increases the speed of masonry. Another important advantage of a light and warm building material is that it requires an adhesive rather than a complex cement-sand mortar

Types and diameters of metal pipes. Metal pipes of large diameters

Steel pipe is a cylindrical tube and is the most used product in the steel industry. The main use of steel pipes is to transport oil, gas and water over long distances. In household appliances, such as refrigerators, ordinary steel pipes are used, as well as in heating and water supply systems

Diameters of polyethylene pipes: external, internal, purpose of pipes

What diameters polyethylene pipes have, you now know. However, for the installation of these products, it is necessary to familiarize yourself with the features of docking. Connections may or may not be detachable. The former provide for the possibility of disassembling the system during operation. To create such a connection, steel flanges are used. During operation, disassembly cannot be carried out if the connection is one-piece

Polyurethane - what is it? Production of polyurethane, products from it

Today, polyurethane is a very popular material. What is it, you will learn in this article

Production of polyurethane foam: technology, raw materials, equipment

Mounting foam from the usual means of sealing window openings has long passed into the status of a full-fledged building material, which is widely used in a variety of types of work. The variety of applications of this product also determines the need for a differentiated approach to the technologies of its manufacture. However, the differences in foam production methods are more of a cosmetic nature, without affecting the basic technological processes