2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:38

An effective way to purify water is to force it through semi-permeable membranes. Filtration processes are classified according to the size of the particles to be separated:

- microfiltration through membranes with pore sizes from 0.05 to 10 microns;

- ultrafiltration - pores from 0.001 µm to 0.05 µm;

- reverse osmosis and nanofiltration - pores 1 nm and below.

Ultrafiltration of water is designed to remove microorganisms and macroscopic inclusions from it that do not pass through the pores of the membrane.

The traditional mechanism of backfill filters is based on gravity cleaning. Ultrafiltration is similar to sifting through a porous sieve, where all particles of larger diameter are separated.

Membrane types

Filter elements are flat sheets or fibers with capillaries. Through the former, wastewater is predominantly ultrafiltered, and the latter are intended forwater treatment.

The fibers are mainly made single-channel, with an inner diameter of about 0.8 mm. They are subjected to frequent stress and can be destroyed by backwashing. Multi-channel fibers contain multiple capillaries and are significantly stronger.

Membranes are made from polymers such as polyestersulfone. Its parameters can be changed by adding other synthetic materials. The wide pH range of the liquids being processed makes it possible to effectively clean the filter elements.

Polymer membranes must be periodically decontaminated, as microbes love to eat organic matter and form colonies on it.

Long-lasting ceramic membrane, which is well washed with detergents. Its price is higher, but the service life reaches 10 years.

Filtration methods

Ultrafiltration water system consists of modules filled with hollow porous fibers. The initial liquid enters the capillaries, after which filtration occurs through the side walls. Reverse feed is also possible.

Flushing is performed by the filtrate with its supply in the opposite direction. Uniform distribution of liquid outside the fibers ensures the removal of deposits from the capillaries. Here it is important to choose the right flushing mode so that the contaminant layer is easier to remove.

Filters operate in two modes, one of which is pressure: water is supplied to the casing of the device under pressure. The immersion method is performed using membranes lowered into an open container. A vacuum is created on the outlet side and liquid is sucked through the filter material.

Modules are arranged vertically. Water enters them from one end, and is discharged from the other. The number of modules in one filter usually does not exceed two units. Due to this, fewer gaskets are required, which reduces the likelihood of leaks. Vertical modules are convenient to maintain and test. They are easy to install and remove.

Filter modes

When ultrafiltration of water is performed, filters can operate in dead-end and tangential modes. In the first case, all the water supplied is purified. The deposits from the membrane are periodically removed during the flushing process or with the drain stream. The membrane fouls quickly and the pressure drop across it must be kept low, which reduces the performance of the apparatus. The method is used for water treatment, with a low concentration of suspensions.

In the tangential mode, the filtered medium circulates along the surface of the membrane and little deposits form on it. The turbulence of the flow in the supply channel makes it possible to purify water with a high concentration of suspended matter. The disadvantages of this method are the increase in energy costs to create a high flow rate and the need to install additional pipelines.

Ultrafiltration parameters

The main parameters of ultrafiltration are:

- Selectivity - the ratio of impurity concentrations incontaminated water (Cin.) and in the filtrate (Cout.): R=(1 - C out. / Сin.) ∙ 100%. For the ultrafiltration process, it is large, which allows you to trap the smallest particles, including bacteria and viruses.

- Filtrate consumption - the amount of purified water per unit time.

- Specific filtrate consumption - the amount of product passing through 1 m2 of the membrane area. Depends on the characteristics of the filter element and the purity of the source water.

- Membrane pressure drop - the difference between the pressure on the supply side and the filtrate side.

- Permeability is the ratio between the specific flow rate of the filtrate and the pressure drop across the membrane.

- Hydraulic efficiency - the ratio between the flow rate of the filtrate and the feed water supplied.

Ultrafiltration for water disinfection

Traditional methods for the removal of microorganisms include technologies using reagents. Ultrafiltration of water consists in the physical separation of microorganisms and colloids from it due to the small size of the membrane pores. The advantage of the method is the removal of the corpses of microorganisms, algae, organic matter and mechanical particles. At the same time, there is no need for special water treatment, which is mandatory in other cases. All you need to do is run it through a 30 micron mechanical filter.

When buying filters, you need to determine the pore sizes of the membranes. To completely remove viruses, hole diameters should be at the level of 0.005 µm. For large pore sizes, the disinfection functionwill not run.

In addition, ultrafiltration technology provides water clarification. All suspended solids are completely removed.

Ultrafiltration water installation contains devices connected in parallel, which provides the necessary performance of the process and the possibility of replacing them during operation.

Water purification before ion exchange filters

Resin is effective at retaining 0.1-1.0 µm colloidal particles, but they quickly clog the granules. Flushing and regeneration are of little help here. It is especially difficult to remove particles of SiO2, which are especially abundant in wells and river water. After clogging, the resin begins to grow microorganisms in places not washed with cleaning solutions.

Ion exchangers are also actively clogged with emulsified oils that cannot be removed. The blockage is so severe that it is easier to change the filter than to separate the oil from it.

Filtering granules of resins are actively clogged with high-molecular compounds. Activated carbon removes them well, but it has a short service life.

Ion exchange resins are effective together with ultrafiltration removing more than 95% of colloids.

Water treatment - ultrafiltration before reverse osmosis

Operating costs are reduced by stepwise installation of filters with a successive reduction in the size of the retained particles. If a coarser cleaning is installed before the ultrafiltration module, then it increases the efficiency of reverse osmosis systems. The latter are sensitive to anionic and non-ionic flocculants if coagulation of contaminants is performed at the preliminary stage.

Large molecular organic matter quickly clogs the pores of reverse osmosis membranes. They are quickly overgrown with microorganisms. Pre-filtering water solves all problems and is cost effective when used with reverse osmosis.

Wastewater treatment

Ultrafiltration wastewater treatment makes it possible to reuse it in industry. They are suitable for use in engineering, and the technogenic load on open water bodies for drinking purposes is reduced.

Membrane technologies are used to treat wastewater from galvanic and textile production, in the food industry, iron removal systems, when removing urea, electrolytes, heavy metal compounds, oil products, etc. from solutions. This increases the efficiency of treatment and simplifies the technology.

With low molecular weight impurities, ultrafiltration can produce pure product concentrates.

Especially important is the problem of separating emulsified oils from water. The advantage of membrane technology is the simplicity of the process, low energy consumption and no need for chemicals.

Surface water treatment

Precipitation and filtration have previously been effective ways to purify water. Impurities of natural origin are effectively removed here, but now technogenic pollutants have appeared, for the removal of whichother cleaning methods are required. Especially many problems are created by the primary chlorination of water, which forms organochlorine compounds. The use of additional purification stages with activated carbon and ozonation increases the cost of water.

Ultrafiltration allows you to get drinking water directly from surface sources: algae, microorganisms, suspended particles and other compounds are removed from it. The method is effective with preliminary coagulation. At the same time, long settling is not required, since the formation of large flakes is not necessary.

Installation of ultrafiltration of water (photo below) allows you to achieve consistently good quality of purified water without the use of complex equipment and reagents.

The use of coagulation methods is becoming ineffective because many organic compounds in water are not detected by the traditional potassium permanganate oxidation method. In addition, the organic content varies widely, making it difficult to select the required concentration of reagents.

Conclusion

Ultrafiltration of water through membranes allows you to achieve its required purity with a minimum consumption of reagents. Wastewater after treatment can be used for industrial purposes.

Ultrafiltration is not always effective. The method does not allow removing some substances, for example, organochlorine compounds and some humic acids. In such cases, multi-stage cleaning is applied.

Recommended:

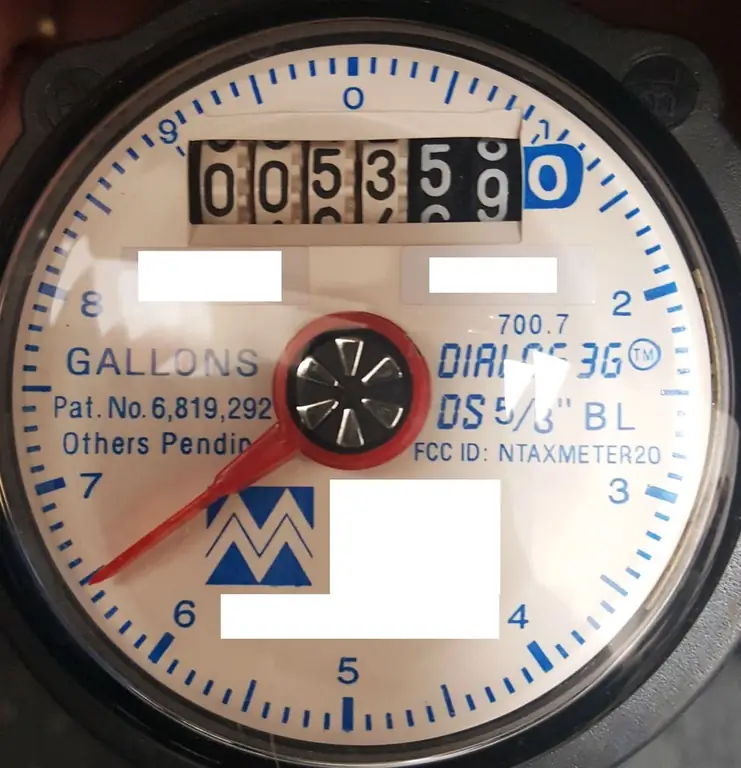

Shelf life of water meters: period of service and operation, verification periods, operating rules and time of use of hot and cold water meters

The shelf life of water meters varies. It depends on its quality, the condition of the pipes, the connection to cold or hot water, the manufacturer. On average, manufacturers claim about 8-10 years of operation of devices. In this case, the owner is obliged to carry out their verification within the time limits established by law. We will tell you more about this and some other points in the article

"Royal Water": customer and employee reviews, addresses, order conditions, delivery and water quality

Royal Water is one of the largest companies in the bottled water market. The company was founded in 1994. An extensive dealer network and a large number of branches determined the presence of the organization in many regions of the country

The rate of water consumption and sanitation. The principle of rationing water consumption

Economical use of all natural resources is the task of each of us. It is no secret that in cities there is a norm of water consumption for each inhabitant, such norms have been developed for industrial enterprises. Moreover, water disposal is also normalized, i.e. sewage

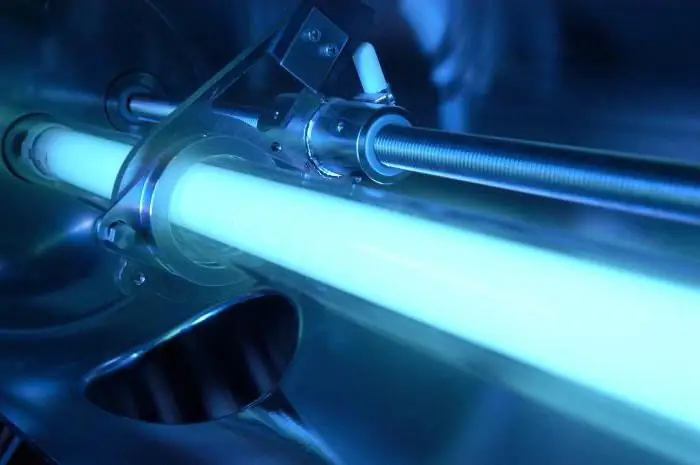

UV water disinfection: principle of operation, installation. Drinking water - GOST valid

Technologies in the field of water treatment do not stand still. Today, many methods are used to ensure the required quality of drinking liquids that meets the requirements of GOST. One of them is ultraviolet disinfection of water. It will be discussed in the article

Recycled water supply - definition, scheme and features. Recycled water supply system

Recycling water supply is created for the purpose of ecological protection of the environment, economy, and also in case of emergency caused by the creation of a small enterprise. Profitability is determined by design calculations. In the future, it will only increase due to the increase in the cost of water and the growth of fines for environmental pollution